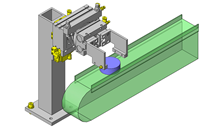

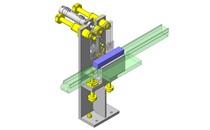

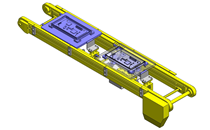

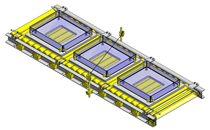

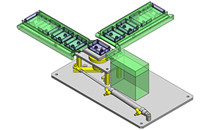

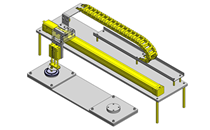

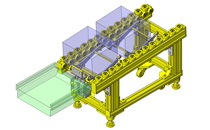

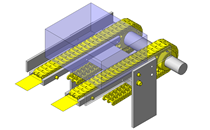

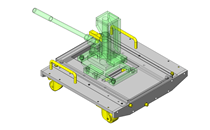

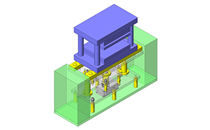

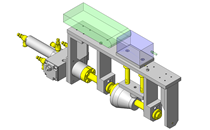

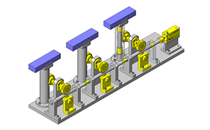

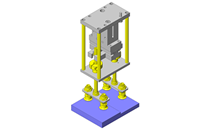

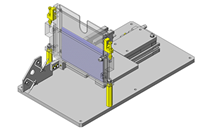

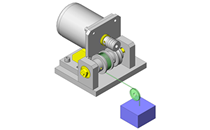

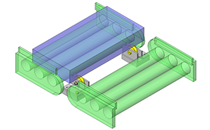

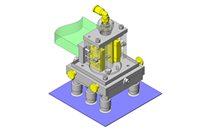

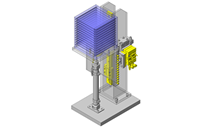

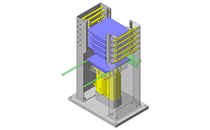

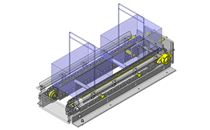

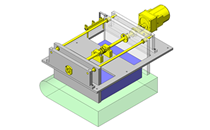

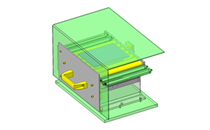

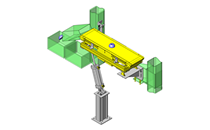

Cylinder with guides

| Product name | Cylinders with Twin Guides |

| Part number | MGCLF16-20 |

| Features | Cylinders having the guides on both ends for usability. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Compact size and allowable lateral load.

Back to page top

Available sizes

■Cylinder with guides (Fixed stroke type)

Tube

I.D. | Bearing | Plain Bushing | Linear Ball Bushing | Cylinder

Width | Overall length

(Below+St) | Thickness |

| St | 10 | 20 | 25 | 30 | 40 | 50 | 75 | 100 | 10 | 20 | 25 | 30 | 40 | 50 | 75 | 100 |

| φ12 | ○ | ○ | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | ○ | ○ | ○ | ○ | ○ | 56 | 39 | 22 |

| φ16 | ○ | ○ | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | ○ | ○ | ○ | ○ | ○ | 62 | 43 | 25 |

| φ20 | - | ○ | - | ○ | ○ | ○ | ○ | ○ | - | ○ | - | ○ | ○ | ○ | ○ | ○ | 72 | 47 | 30 |

| φ25 | - | ○ | - | ○ | ○ | ○ | ○ | ○ | - | ○ | - | ○ | ○ | ○ | ○ | ○ | 86 | 47.5 | 38 |

| φ32 | - | - | ○ | - | - | ○ | ○ | ○ | - | - | ○ | - | - | ○ | ○ | ○ | 112 | 48 |

| φ50 | - | - | ○ | - | - | ○ | - | ○ | - | - | - | - | - | - | - | - | 146 | 72 | 60 |

*Sensor sold separately

Back to page top

Accuracy Info

■Non-Rotational Accuracy

Non-Rotational Accuracy: A deviation angle centered on the piston rod, expressing the backlash caused by the clearance between the guide rod and the bearing.

Tube

I.D. | Non-rotating accuracy of tip link bar |

| Plain Bushing | Linear Bushing |

| φ12 | ±0.12° | ±0.06° |

| φ16 | ±0.10° | ±0.06° |

| φ20 | ±0.09° | ±0.05° |

| φ25 | ±0.08° | ±0.05° |

| φ32 | ±0.06° | ±0.04° |

| φ50 | ±0.05° | - |

Back to page top

Performance info.

■Guided cylinder usage pressure range

Min. pressure(MPa): 0.1

Max. pressure(MPa): 1.0

Proof pressure(MPa): 1.5

■Theoretical thrust

(N)

Tube

I.D. | Actuating

direction | Operating pressure (MPa) |

| 0.4 | 0.5 |

| φ12 | Push | 45 | 57 |

| Pull | 34 | 42 |

| φ16 | Push | 80 | 101 |

| Pull | 60 | 75 |

| φ20 | Push | 126 | 157 |

| Pull | 94 | 118 |

| φ25 | Push | 196 | 245 |

| Pull | 151 | 189 |

| φ32 | Push | 322 | 402 |

| Pull | 241 | 302 |

| φ50 | Push | 785 | 982 |

| Pull | 660 | 825 |

■Allowable rotational torque

The following shows the dynamic allowable value with rotational torque T applied to the tips of the guide rods.

(N・m)

Tube

I.D. | Bearing

type | Stroke |

| 10 | 20 | 25 | 30 | 40 | 50 | 75 | 100 |

| φ12 | Plain Bushing | 0.50 | 0.40 | - | 0.33 | 0.28 | 0.25 | 0.77 | 0.65 |

| Linear bushing | 0.41 | 0.31 | - | 0.25 | 0.69 | 0.59 | 0.40 | 0.32 |

| φ16 | Plain Bushing | 0.91 | 0.75 | - | 0.64 | 0.56 | 0.49 | 1.25 | 1.06 |

| Linear bushing | 0.76 | 0.60 | - | 0.49 | 1.14 | 1.02 | 0.79 | 0.65 |

| φ20 | Plain Bushing | - | 1.43 | - | 1.23 | 1.08 | 0.96 | 1.51 | 1.27 |

| Linear bushing | - | 1.12 | - | 0.93 | 2.12 | 1.90 | 1.50 | 1.24 |

| φ25 | Plain Bushing | - | 2.26 | - | 1.94 | 1.71 | 1.52 | 2.38 | 2.00 |

| Linear bushing | - | 1.98 | - | 1.65 | 3.75 | 3.37 | 2.68 | 2.22 |

| φ32 | Plain Bushing | - | - | 6.71 | - | - | 5.24 | 4.30 | 3.64 |

| Linear bushing | - | - | 3.61 | - | - | 2.55 | 6.48 | 5.41 |

| φ50 | Plain Bushing | - | - | 13.0 | - | - | 10.8 | - | 10.6 |

■ Allowable lateral load

The following shows the dynamic allowable values with lateral load W (load perpendicular to the guide rod) applied to the tips of the guide rod.

(N)

Tube

I.D. | Bearing

type | Stroke |

| 10 | 20 | 25 | 30 | 40 | 50 | 75 | 100 |

| φ12 | Plain Bushing | 24 | 19 | - | 16 | 14 | 12 | 37 | 31 |

| Linear bushing | 20 | 15 | - | 12 | 33 | 29 | 19 | 16 |

| φ16 | Plain Bushing | 40 | 33 | - | 28 | 24 | 21 | 55 | 46 |

| Linear bushing | 33 | 26 | - | 21 | 50 | 44 | 34 | 28 |

| φ20 | Plain Bushing | - | 52 | - | 45 | 39 | 35 | 55 | 46 |

| Linear bushing | - | 41 | - | 34 | 77 | 69 | 54 | 45 |

| φ25 | Plain Bushing | - | 69 | - | 60 | 52 | 47 | 73 | 62 |

| Linear bushing | - | 61 | - | 51 | 115 | 104 | 82 | 68 |

| φ32 | Plain Bushing | - | - | 166 | - | - | 131 | 107 | 91 |

| Linear bushing | - | - | 90 | - | - | 34 | 162 | 135 |

| φ50 | Plain Bushing | - | - | 296 | - | - | 245 | - | 241 |

Back to page top

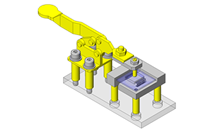

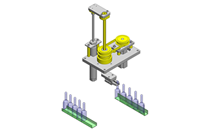

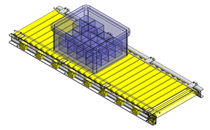

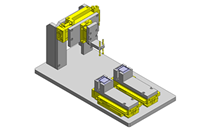

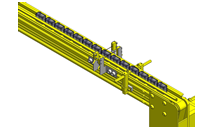

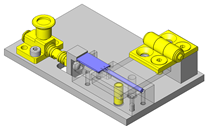

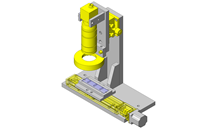

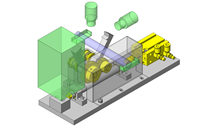

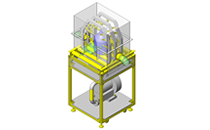

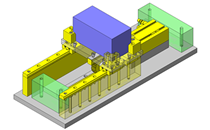

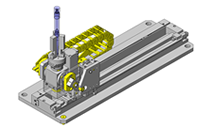

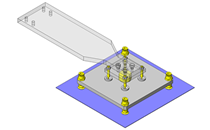

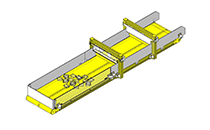

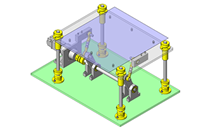

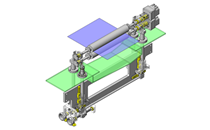

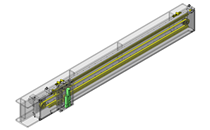

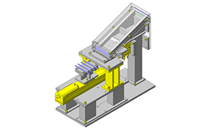

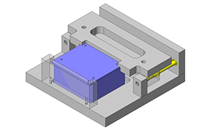

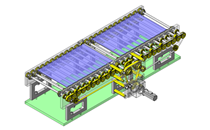

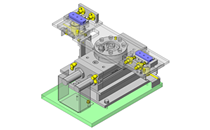

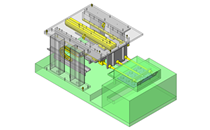

Feed Finger

| Product name | Feed Fingers |

| Part number | ATBST10B-S-BTS |

| Features | Applicable for Pallet Back-Feed Prevention of Carrier Line |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Suitable for approx. positioning of pallets

Back to page top

Risk info.

Premature claw wear

Back to page top

Available sizes

Feed Finger

●Claw specifications

| Material | Surface treatment | Hardness | | Straight | Round |

| Width | 7 | 10 | 14 | 20 | 28 | 7 | 10 | 14 | 20 | 28 |

| 1018 Carbon Steel | Electroless nickel plating | Carburizing (Depth 0.1)HV400-500 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| 304 Stainless Steel | − | − | - | ○ | - | - | - | - | ○ | - | - | - |

| Tufftride | Tufftride(Depth 0.01)HV1000 | - | ○ | - | - | - | - | ○ | - | - | - |

| MC Nylon | − | − | ○ | ○ | ○ | - | - | ○ | ○ | ○ | - | - |

● Body·Pin specifications

| Body | Pin |

| Material | Surface treatment | Shape | Claw width(Straight/Round) | Material | Surface treatment |

| 7 | 10 | 14 | 20 | 28 | | |

| 1018 Carbon Steel | Electroless

nickel

plating | Side holes

(Screw holes) | ○ | ○ | ○ | - | - | 1045 Carbon Steel | Electroless

nickel

plating |

Side holes

(Through holes) | - | ○ | ○ | - | - |

Side holes

(Tapped) | ○ | ○ | ○ | - | - |

Bottom

mount | ○ | ○ | ○ | ○ | ○ |

| π shape | ○ | ○ | ○ | ○ | ○ |

| 304 Stainless Steel | − | Side holes

(Bolt) | - | ○ | - | - | - | 303 Stainless Steel | − |

Side holes

(Through holes) | - | ○ | - | - | - |

Side holes

(Tapped) | - | ○ | - | - | - |

Bottom

mount | - | ○ | - | - | - |

| π shape | - | - | - | - | - |

●Spring specifications

| Material | Spring type |

| 304 Stainless Steel | Soft, Hard |

■Dimensions

| Claw material | Claw width | Claw shape | Spring

Type | Body shape | Body width | Overall height | Body height | Body length | Stroke |

| Max. | Min. |

1018 Carbon Steel、

MC Nylon | 7 | Straight·

Round | Soft·

Hard | Side holes(Screw) | 12 | 29 | 22.5 | 30

(Short) | 5 | 3 |

| Side holes(Tapped) |

| Bottom mount |

| π shape | 20.5 | 14 |

| 7 | Side holes(Through holes) | 12 | 38 | 31 | 40

(Standard) | 5 | 3 |

| Side holes(Tapped) |

| Bottom mount |

| π shape |

| 1018 Carbon Steel、 304 Stainless Steel、MC Nylon | 10 | Side holes(Through holes) | 19 | 38 | 31 | 40 | 5 | 3 |

| Side holes(Through holes) |

| Side holes(Tapped) |

| Bottom mount |

| π shape |

| 14 | Side holes(Through holes) | 25 | 55.5 | 43 | 55 | 10 | 5 |

| Side holes(Through holes) |

| Side holes(Tapped) |

| Bottom mount |

| π shape | 66.5 | 54 |

| 1018 Carbon Steel | 20 | Bottom mount | 38 | 63 | 49 | 65 | 10 | 5 |

| π shape | 78 | 64 |

| 28 | Bottom mount | 50 | 83 | 64 | 80 | 12 | 7 |

| π shape | 101 | 82 |

*Please check with product pages for claw, body shape details, detailed dimensions, and material.

Back to page top

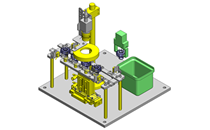

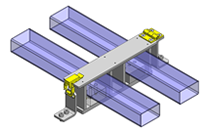

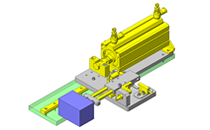

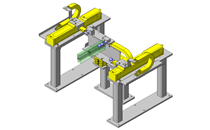

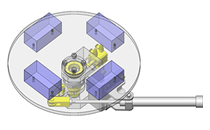

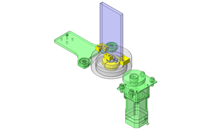

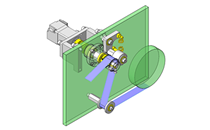

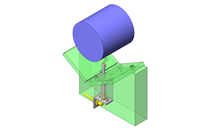

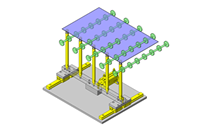

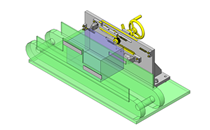

Mechanism Info.

■Feed finger structural diagram

| Key | Name | Qty. |

| ① | Claw | 1 |

| ② | Spring | 1 |

| ③ | Body | 1 |

It has a pivoted claw. When a pallet passes over the top, the claw returns by a spring, preventing reverse traveling of the pallet.

Back to page top

Performance info.

■Spring load of Feed Finger (N)

Claw

(Straight/Round) | Spring type | Set | Stroke3 | Stroke5(7) | Stroke10(12) |

| Width | Body | Spring

top section | Claw tip | Spring

top section | Claw tip | Spring

top section | Claw tip | Spring

top section | Claw tip |

| 7 | Short | Soft | 0.4 | 0.3 | 1.1 | 0.7 | 1.5 | 1.0 | - | - |

| Hard | 1.4 | 1.0 | 2.4 | 1.6 | 2.9 | 2.0 | - | - |

| 7 | Standard | Soft | 0.3 | 0.2 | 1.0 | 0.7 | 1.5 | 1.0 | - | - |

| Hard | 1.7 | 1.1 | 2.6 | 1.7 | 3.1 | 2.1 | - | - |

| 10 | - | Soft | 0.3 | 0.2 | 1.0 | 0.7 | 1.5 | 1.0 | - | - |

| Hard | 1.8 | 1.2 | 2.6 | 1.7 | 3.2 | 2.1 | - | - |

| 14 | - | Soft | 0.9 | 0.7 | 1.3 | 1.1 | 1.7 | 1.3 | 2.4 | 1.9 |

| Hard | 2.6 | 2.1 | 3.1 | 2.5 | 3.5 | 2.8 | 4.3 | 3.5 |

| 20 | - | Soft | 2.3 | 1.8 | - | - | 3.0 | 2.4 | 3.8 | 3.0 |

| Hard | 3.6 | 2.8 | - | - | 4.5 | 3.5 | 5.5 | 4.3 |

| 28 | - | Soft | 3.7 | 2.6 | - | - | 5.2 | 4.0 | 6.3 | 4.8 |

| Hard | 4.9 | 3.4 | - | - | 6.7 | 5.2 | 8.0 | 6.2 |

*Stroke 5·10 value for 28A, 28B will be stroke 7·12 respectively.

Back to page top

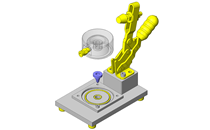

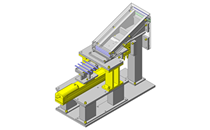

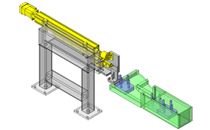

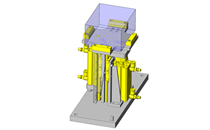

IDEA NOTE Prevent pallet looseness.

By using a feed finger with a round claw, the feed finger and pallet can be placed closer with each other, minimizing play.