(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

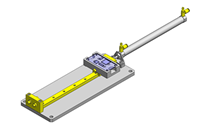

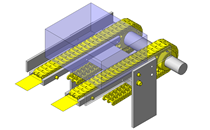

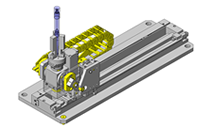

- > No.000160 Cylinder Stroke with Rack and Gear Mechanism

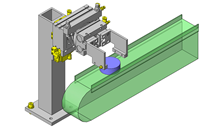

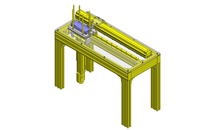

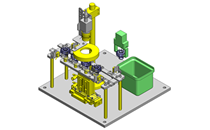

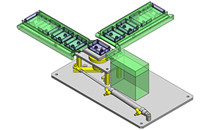

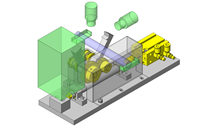

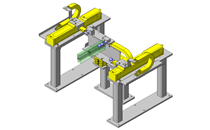

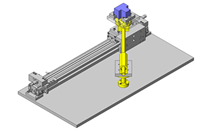

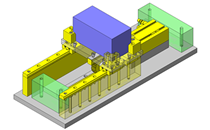

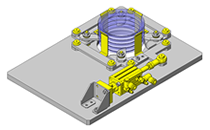

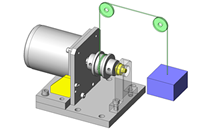

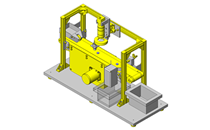

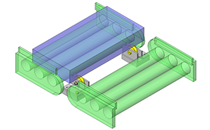

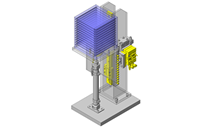

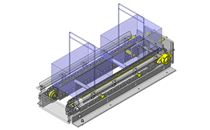

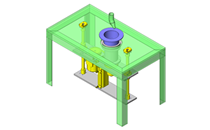

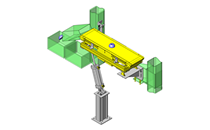

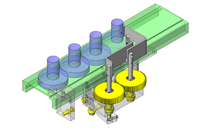

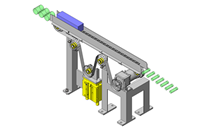

No.000160 Cylinder Stroke with Rack and Gear Mechanism

32

32

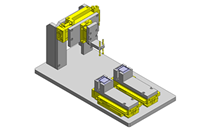

Stroke speed is increased by adding gear and rack to cylinder push.

Relevant category

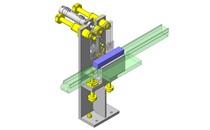

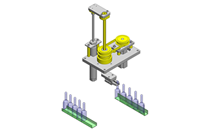

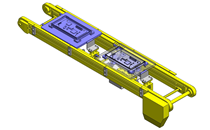

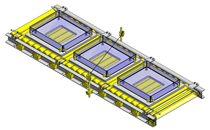

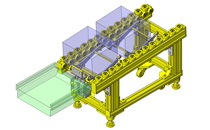

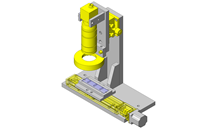

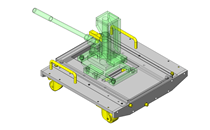

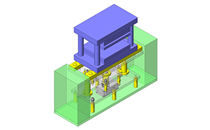

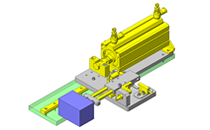

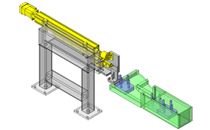

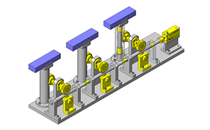

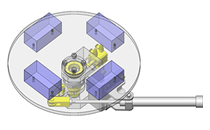

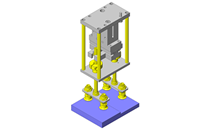

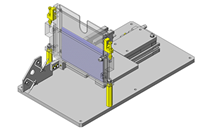

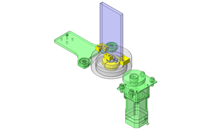

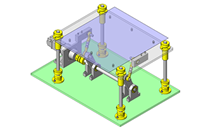

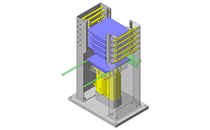

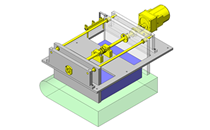

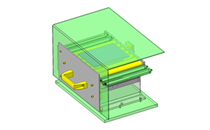

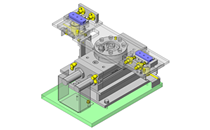

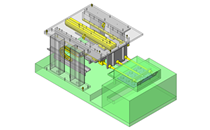

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Operation

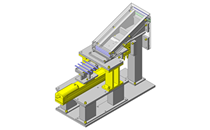

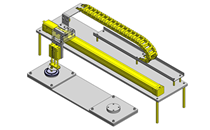

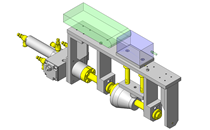

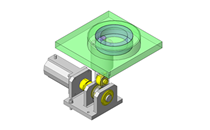

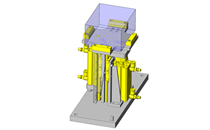

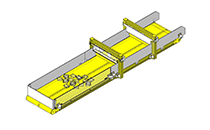

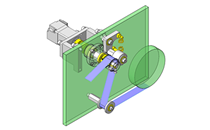

- There is a rack and gear set beneath the workpiece platform that allows it to advance faster as the cylinder pushes the gear forward.

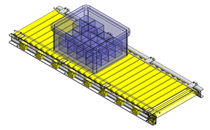

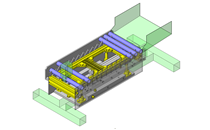

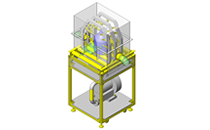

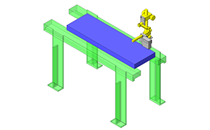

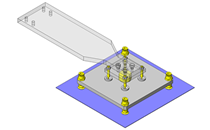

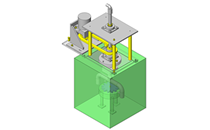

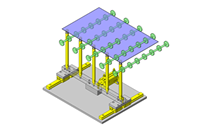

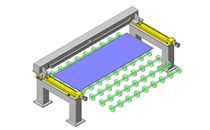

Target workpiece

- Shape: block

- Material: tungsten

- Workpiece size: 50x55x90mm

Design Specifications

Operating Conditions or Design Requirements

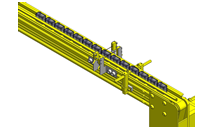

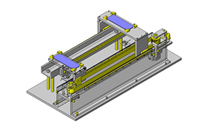

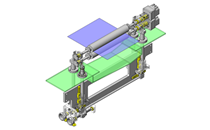

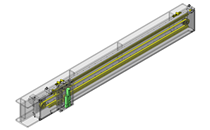

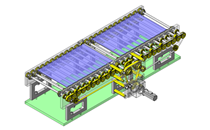

- Cylinder advance stroke: 20mm

- Movable rack stroke: 50mm

- Outer dimensions: L244xW160xH102mm

Required Performance

- Load: 47N

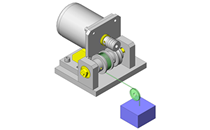

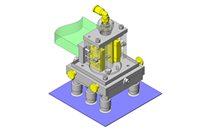

Selection Criteria for Main Components

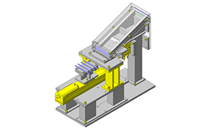

- Select wear resistant materials for the racks and pinion.

Design Evaluation

Verification of main components

- Confirmation of cylinder output

- Conditional Value

- When plant air pressure is 0.5MPa and cylinder inner diameter is 20mm,

Cylinder thrust (pushing side): 157N

Cylinder thrust (pulling side): 132N

Workpiece mass M₁ = 4.8kg, work table mass M₂ = 11.5N

Linear guide friction coefficientμ=0.005, gravitational acceleration g = 9.8m/s²

Cylinder stroke:st₁=20mm

Rack stroke: st₂=50mm - Work conservation law

- If we assume that the workload on the cylinder side and that on the rack side are the same,

Fc×st₁=F₁×st₂

Fc=F₁×st₂/st₁

Here, load applied by workpiece: F₁ is

F₁=(M₁+M₂)×μ =(48+11.5)×0.005=0.30N

- Therefore, required cylinder thrust Fc is

-

- Conclusion

Other Design Consideration

- Select appropriate gear ratio to produce the desire additional speed.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category