(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000216 90-Degree Pallet Transfer Mechanism

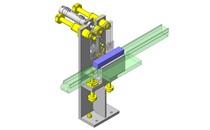

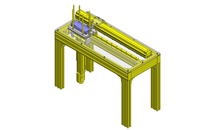

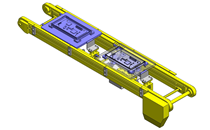

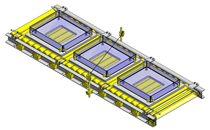

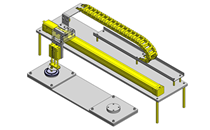

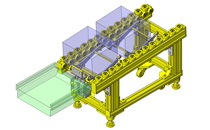

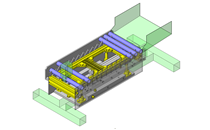

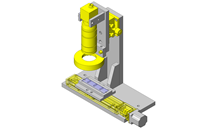

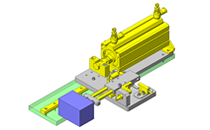

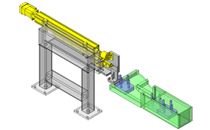

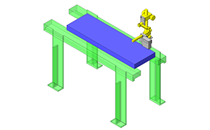

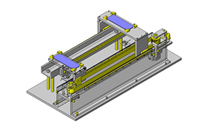

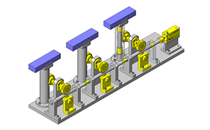

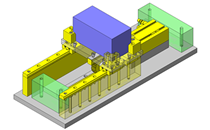

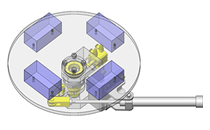

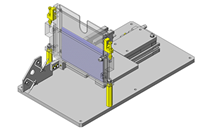

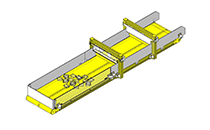

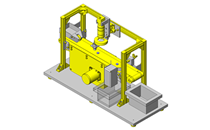

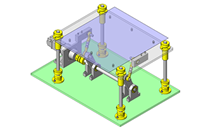

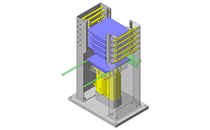

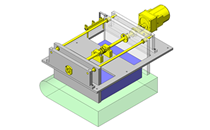

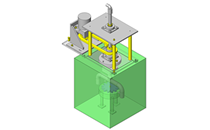

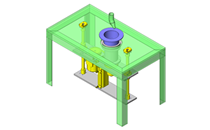

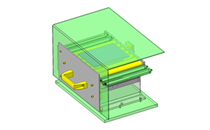

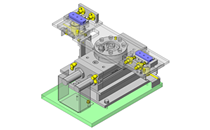

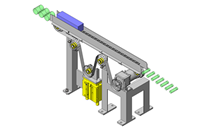

No.000216 90-Degree Pallet Transfer Mechanism

47

47

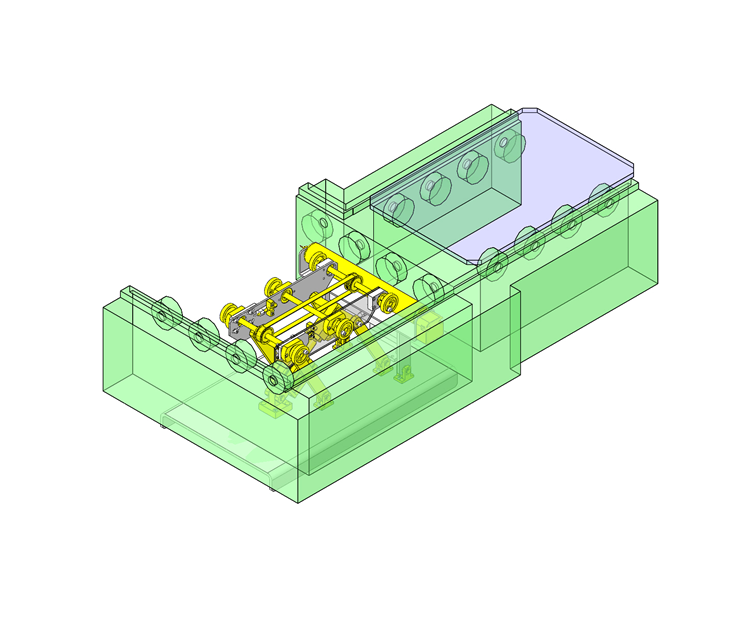

Transferring pallets at 90-degree without de-energizing the conveyors.

Relevant category

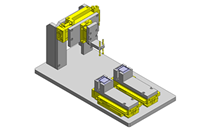

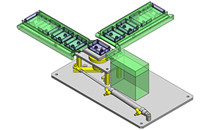

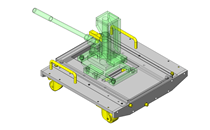

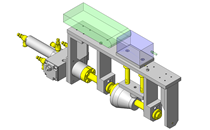

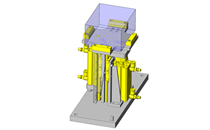

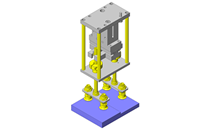

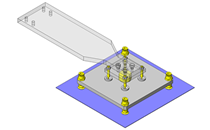

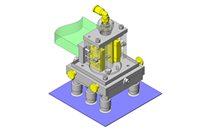

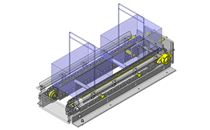

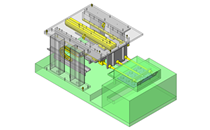

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Purpose

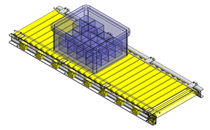

- To transfer pallet at 90-degree angle from one conveyor to another.

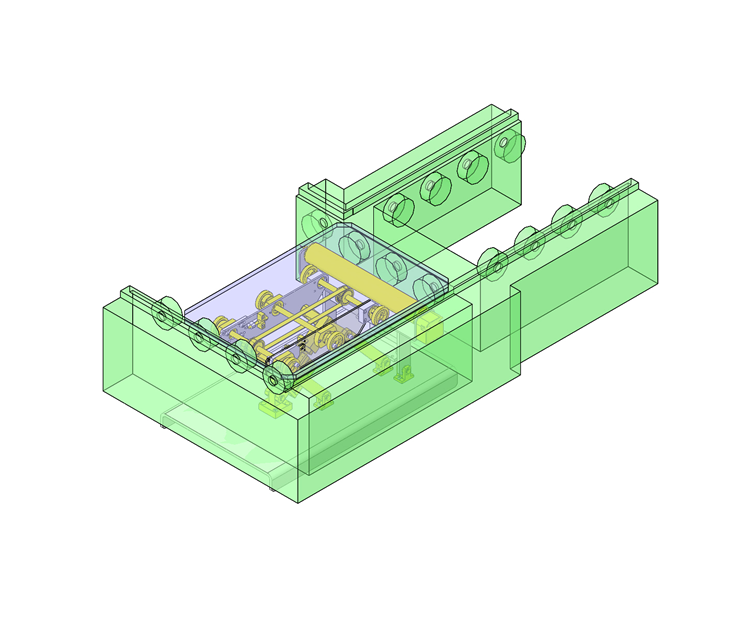

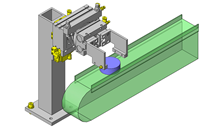

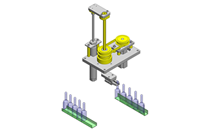

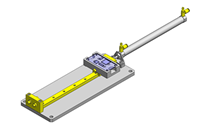

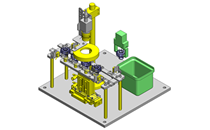

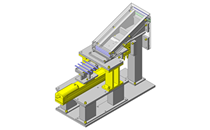

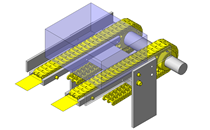

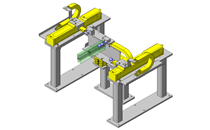

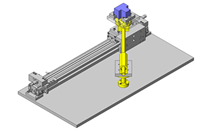

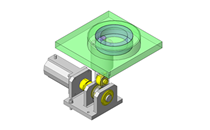

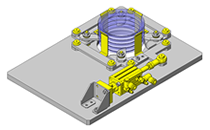

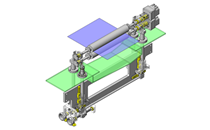

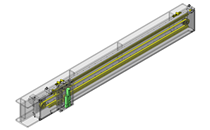

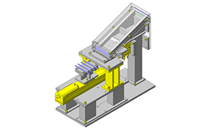

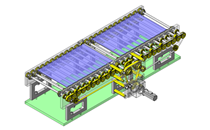

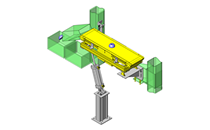

- Operation

- At the transfer position, bellow the conveying height, is the lifting and transfer mechanism. When a pallet is in the transfer position the cylinder moves the unit and lifts the workpiece from conveyor. To make 90-degree transfer drive roller pulls the workpiece onto the next station. Besides drive roller (motor powered) workpiece is also supported by 3 sets of free-wheeling rollers as part of the lift and transfer unit. When the pallet leaves, the transfer unit cylinders retract and transfer unit is once again below the conveying height.

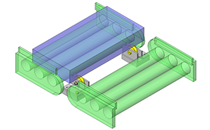

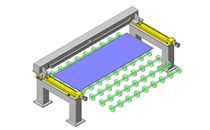

Target workpiece

- Pallet

- Size:W450×D300×H10mm

- Weight:3.7kg

- Load capacity:8kg

Design Specifications

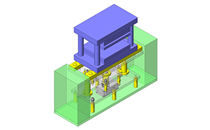

Operating Conditions or Design Requirements

- Operational Specifications

- To conduct right angle transfer of pallets smoothly and prevent the conveyor rollers from being damaged, the transfer action should be started after the pallet is lifted.

- Transfer speed: 12 to 14 (m/min)

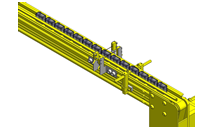

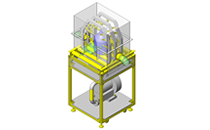

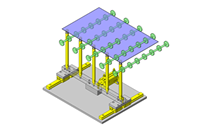

- Dimensions

- W500×D300×H250mm

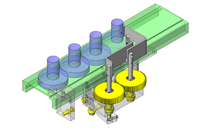

Selection Criteria for Main Components

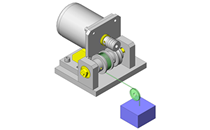

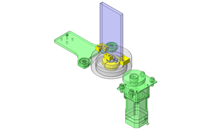

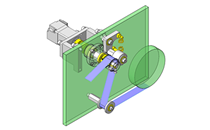

- A cylinder is selected based on the pallet and load capacity.

- A motor roller is selected based on load capacity.

- The drive roller diameter is selected based on needed transfer speed.

Design Evaluation

Verification of main components

- A motor roller and a cylinder is selected based on the workpiece load.

- Conditional value: spring constant k = 9.8N/mm, spring free length X0 = 65mm, spring length when roller makes contact X1 = 47.2mm, distance between roller base rotation shaft and spring part Lk1 = 83mm, distance between roller base and roller contact point Lk2 = 158mm, air cylinder thrust at 0.5 MPa Fs0 = 402N, cylinder efficiency η = 0.8, cylinder thrust angle θ1 = 36°, distance between cylinder link rotation shaft and cylinder thrust point Ls1 = 150mm, distance between cylinder link and roller contact point Ls2 = 140.6mm, angle formed by motor roller shaft and drive roller shaft θ2 = 30.4°, angle formed by cylinder link and cylinder thrust direction θ3 ≈ 90°, motor roller strength Fm = 490N, motor roller diameter D1 = 42.7mm, drive roller diameter D2 = 40mm, motor roller speed V1 = 12.7m/min, friction coefficient between drive roller and pallet μ1 = 0.1, friction coefficient between motor roller and drive roller μ2 = 0.6 (metal and rubber), rated tangential force of motor roller N1 = 14.2N, workpiece weight M = 3.7 + 8 = 11.7kg, gravitational acceleration g = 9.8m/s²

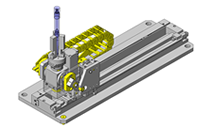

- Selection of motor roller

- Drive roller strength

[Force by spring]

If we put Fk1N as spring force and Fk2N as the force applied to the roller contact point, from the balance of moment around the roller base rotation shaft,

Fk1×Lk1=Fk2×Lk2

Fk2={k×(X0-X1)}×Lk1/Lk2={9.8×(65-47.2)}×83/158=91.6N

Therefore, the force in the normal direction applied by the spring to the roller contact face:Fk=Fk2×cosθ2=91.6×cos30.4=79N

[Force by cylinder]

If we put Fs1 as cylinder thrust and Fs2 as force applied to the roller contact point by the cylinder, from θ3 ≈ 90° and the balance of moment around the cylinder link rotation shaft,

Fs1×Ls1=Fs2×Ls2

Fs2={P0×η}×Ls1/Ls2={402×0.8}×150/140.6=343.1N

Angle formed by the cylinder thrust direction, drive roller shaft, and motor roller shaft:θ4=θ1+θ2=66.4°

Therefore, the force in the normal direction applied to the roller contact face by the cylinder:Fs=Fs2×cosθ4=343.1×cos66.4=137.4N

[Confirmation of roller strength]

From Fs > Fk, push force to motor roller:F=Fk=79N<490N=Fm

⇒As Fm > Fk, the condition is met. - Transfer Speed

As the roller is placed in between, considering the roller ratio,

transfer speed: V2 = V1 x D1/D2 = 12.7 x 42.7/40 = 13.5m/min, hence, the condition (12 to 14m/min) is met. - Pull force of drive motor

Maximum transmission force of motor roller and drive roller: P = F x μ2 = 79 x 0.6 = 47.4N

As N1 < P, the tangential force of the motor roller is transmitted to the drive roller without loss.

[Roller transfer capability]

Required tangential force of drive roller: N2 = 9.8 x M x μ1 = 9.8 x 11.7 x 0.1 = 11.5N

Considering the roller ratio, the required tangential force of the motor roller: N3 = N2 x D1/D2 = 11.5 x 43.7/40 = 12.3N < 14.2N = N1

⇒As N1 > N3, the condition is met.

- Drive roller strength

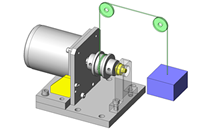

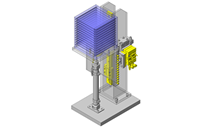

- Selection of air cylinder

- Confirmation of lift cylinder thrust

As links are used in this mechanism,

Lifting power: Fu = Fs0 x η x sinθ1 = 402 x 0.8 x sin36° = 189N

Workpiece weight:M×g=114.7N<189N=Fu

⇒The condition is met.

- Confirmation of lift cylinder thrust

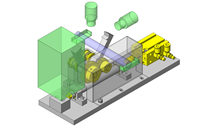

Other Design Consideration

- Air cylinder and links allows lift unit to fully engage the pallet and allows drive roller to stay in contact with pallet during transfer.

- Although this mechanism is designed assuming the transfer conveyor height as 200 mm, an arrangement with a lower design height is also possible.

- Movement in the direction opposite to this setting is also possible.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category