(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

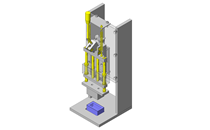

- > No.000007 Stacking Fixture

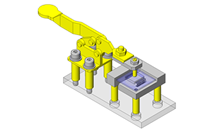

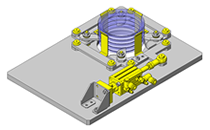

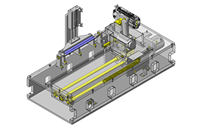

No.000007 Stacking Fixture

13

13

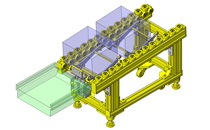

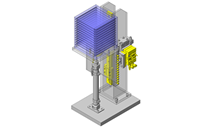

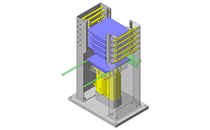

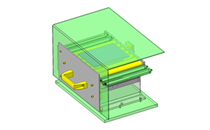

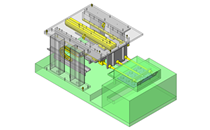

Stackable workpiece holding fixture

Relevant category

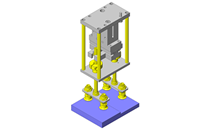

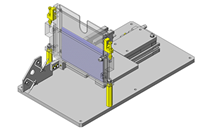

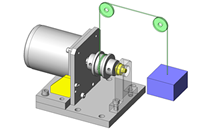

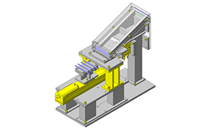

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

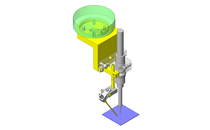

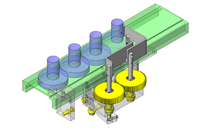

- A fixture to retain workpieces for adhesive curing.

Points for use

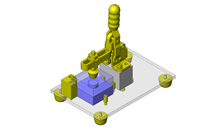

- Since workpieces are molded plastic, the retaining section is made of urethane rubber to prevent scratches.

Target workpiece

- Molded plastic product

External dims.: φ61.5 x H62mm

Weight: 30g/pc.

Design Specifications

Operating Conditions or Design Requirements

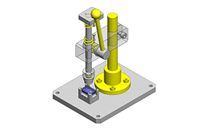

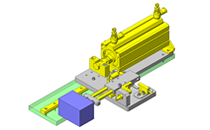

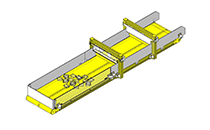

- External dimensions:

(1st level) W300 x D215 x H90mm

(nth level) W300 x D215 x H155mm - Fixture weight: 1.3kg / Level

Selection Criteria for Main Components

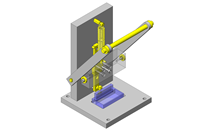

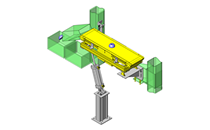

- Hex posts

- In order to make stacking possible, select post with both ends tapped and use extra low head screws with flat supporting heads.

Design Evaluation

Other Design Consideration

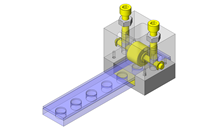

- Urethane rubber is utilized in order to prevent workpiece scratching.

- In order to prevent the top level from falling off, hex posts are inserted in counterbores on the plate.

Explore Similar Application Examples

Page

-

/

-