(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000024 Semi-automatic Grinding Device

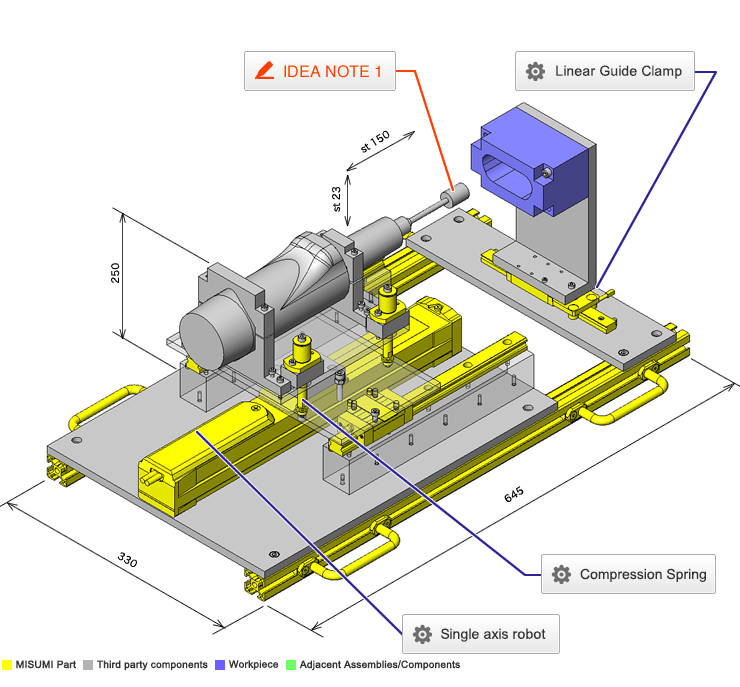

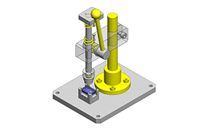

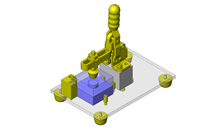

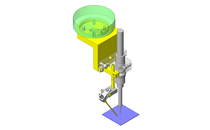

No.000024 Semi-automatic Grinding Device

75

75

A single axis robot with vertical movement controlled by hand.

Relevant category

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

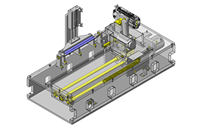

- A fixture in which a grinder is moved horizontally by a single axis robot, and vertically by hand.

- The combination blends creativity and touch with precise movements.

Points for use

- Vertical movements are supported by linear bushings and shafts.

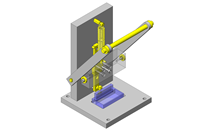

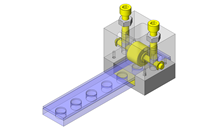

- Horizontal movements of the grinder are controlled by a single axis actuator.

Target workpiece

- Cast products:

External Dimensions: W110 x H75 x t20

Weight: 0.88kg

Design Specifications

Operating Conditions or Design Requirements

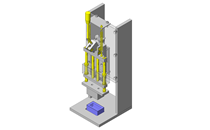

- External dims.: W645 x D330 x H250

- Horizontal stroke: 150mm

- Vertical stroke: 23mm

Required Performance

- Feeding positioning accuracy: ±0.02mm

Selection Criteria for Main Components

- Single axis robot

- Based on transported mass: 86.24N

select an actuator with a maximum load capacity exceeding what is transported. - Maximum push force of selected actuator is 120N.

- Based on transported mass: 86.24N

- Spring

- Select a spring type with a spring constant capable of supporting the grinders weight while stopped.

Design Evaluation

Verification of main components

- Verify that the spring will be able to support the grinder.

- Spring load

- Calculation formula: Reaction force F = kx

- Assumed operating load (4 pcs. Used): 86.24N

- Assumed max. deflection when pushing in the grinder: x = 44mm (21mm when setting (set length 59mm, free length 89mm), Stroke 23mm)

- Spring constant: k = 86.24 / 4 / 44 = 0.49 N/mm is selected.

Other Design Consideration

- Actuator selection is based on load capacity and stroke length.

- Linear guides are used to stabilize the horizontal motion of the system.

- Linear bushings are used to stabilize the vertical motion.

- The actuator and linear guides are connected through cam followers fitted in precise slots provided by the actuator table. This constrains the travel direction.

Explore Similar Application Examples

Page

-

/

-