(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

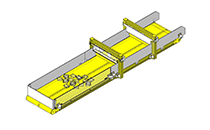

- > No.000060 Film Heat Cutting Mechanism

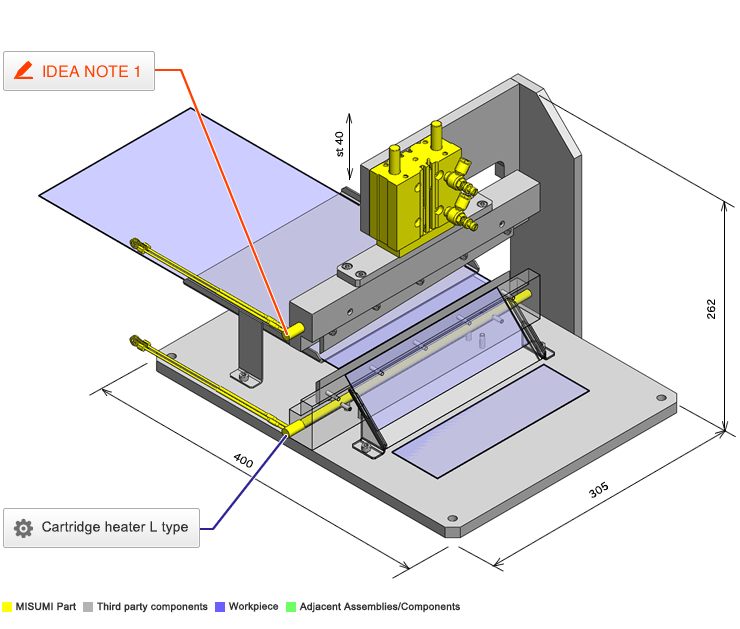

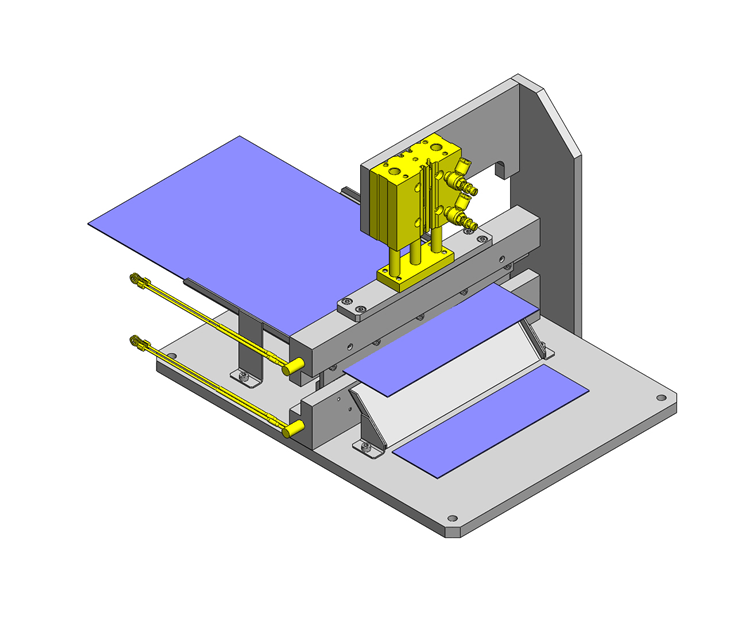

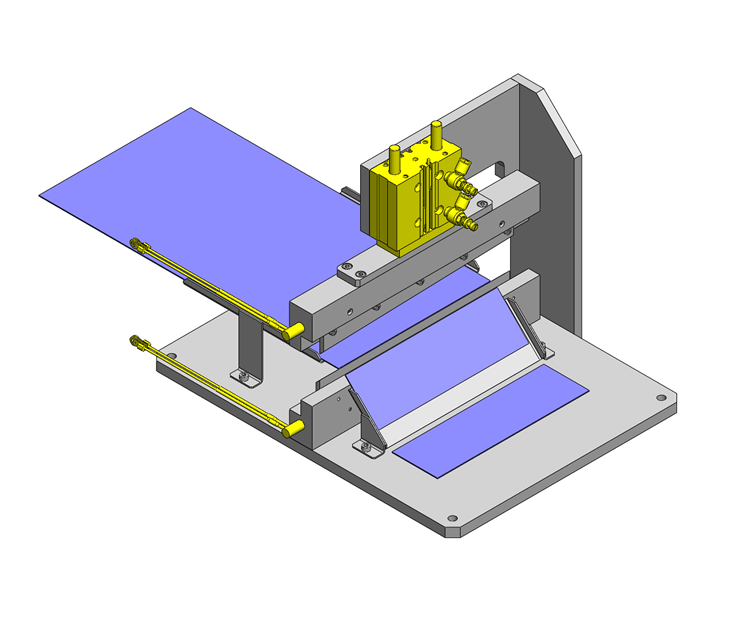

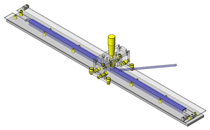

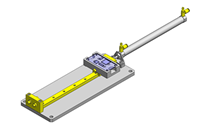

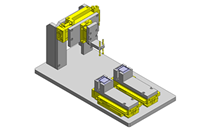

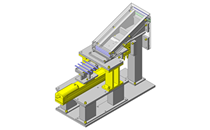

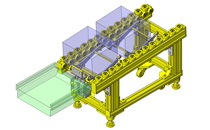

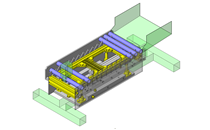

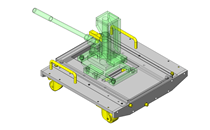

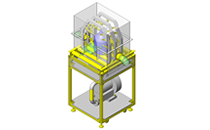

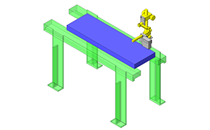

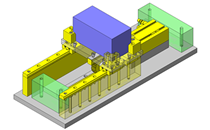

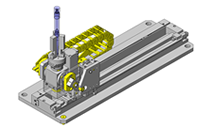

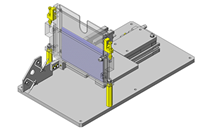

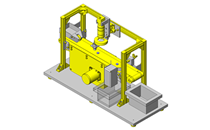

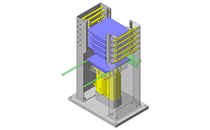

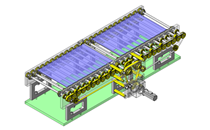

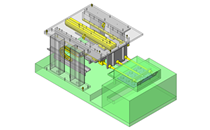

No.000060 Film Heat Cutting Mechanism

56

56

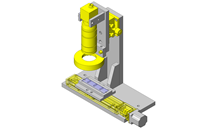

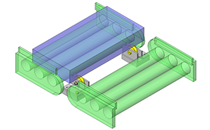

A heated blade is used to reduce the required cutting force.

Relevant category

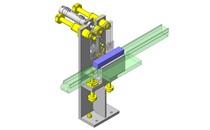

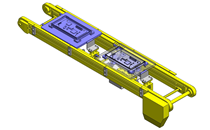

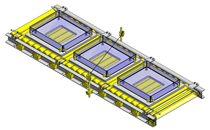

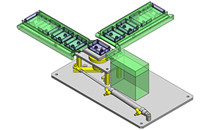

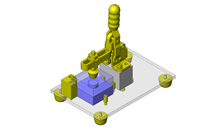

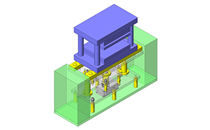

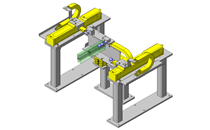

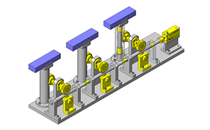

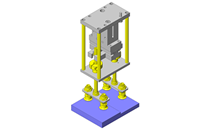

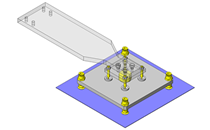

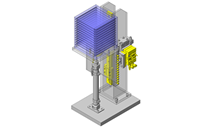

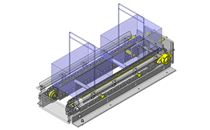

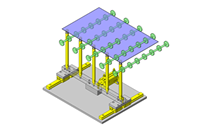

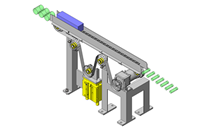

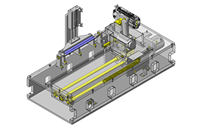

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

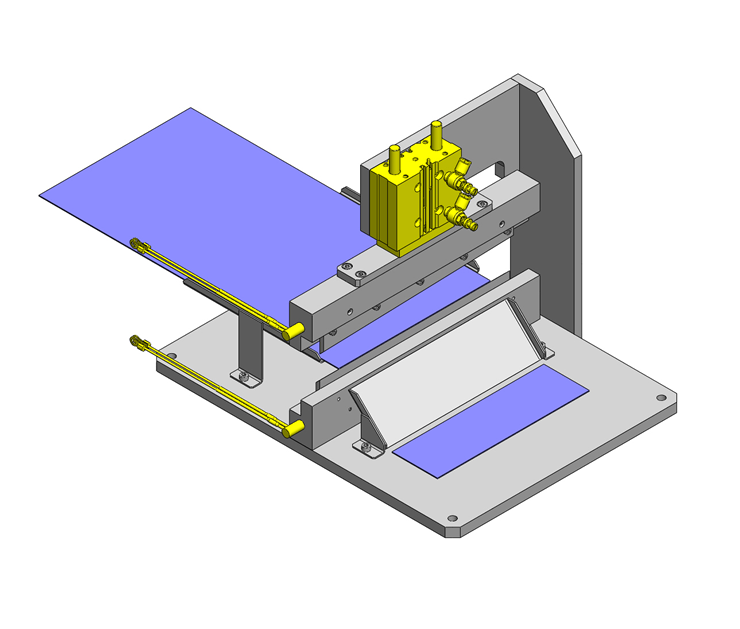

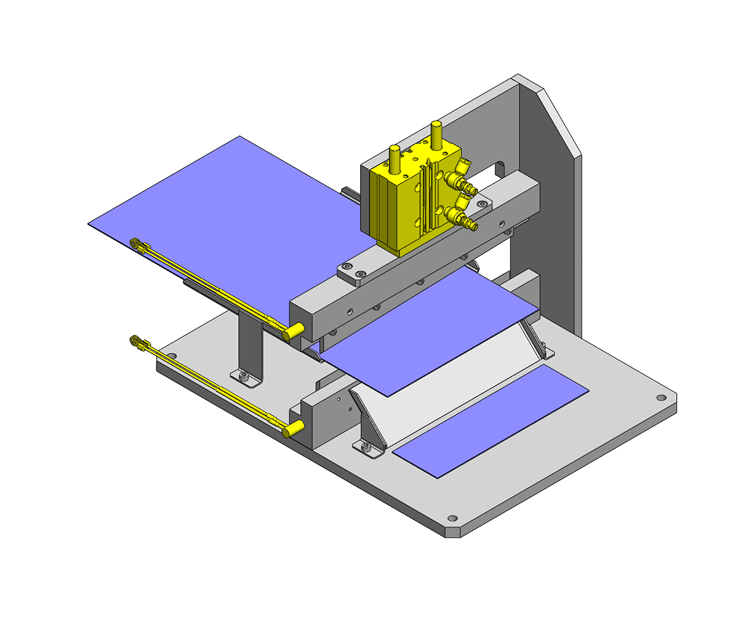

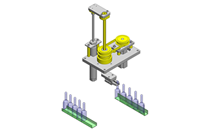

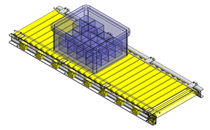

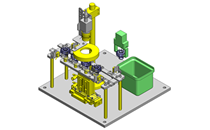

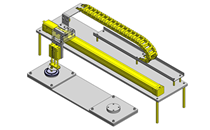

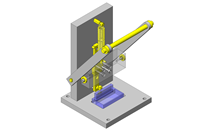

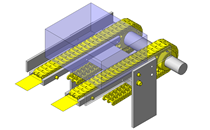

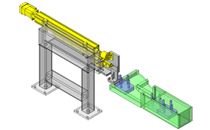

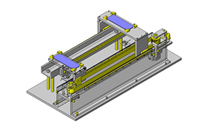

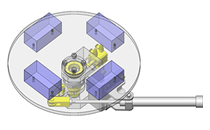

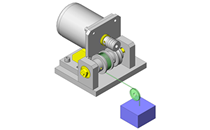

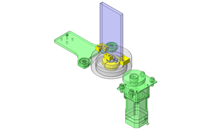

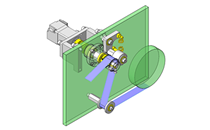

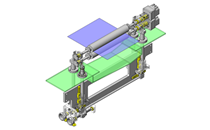

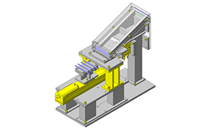

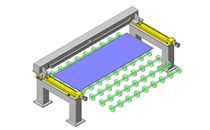

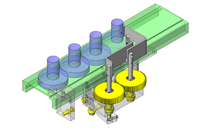

- Combining a cartridge heater with a blade to cut specified lengths of resin belt.

Target workpiece

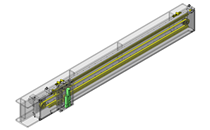

- Thin resin belt.

- Workpiece size: Width 200, Thickness 1mm

Design Specifications

Operating Conditions or Design Requirements

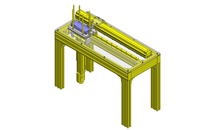

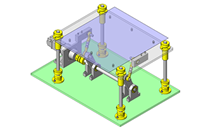

- External dims.: W305 x D400 x H262 mm

- Stroke: 40mm

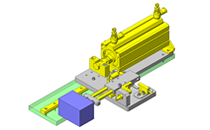

Selection Criteria for Main Components

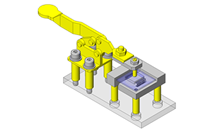

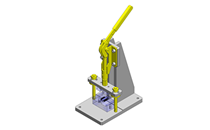

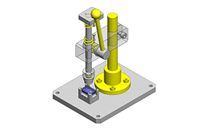

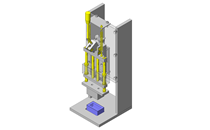

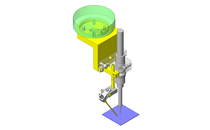

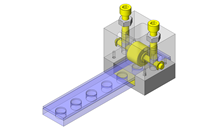

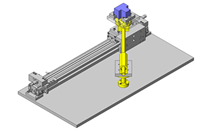

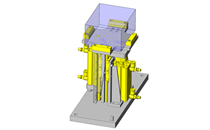

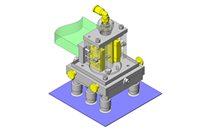

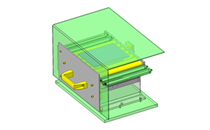

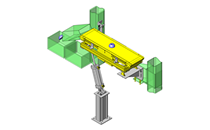

- Cartridge heater

- The electrical wire harness is perpendicular to the heater.

Design Evaluation

Verification of main components

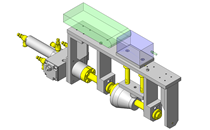

Verify the electric power density of the heater based on the required amount of heat.

- Conditional value: Mass of heated object M = 3 kg

Specific heat Hc = 0.110 for the object to be heated [kcal / kg ℃]

Temperature rise Ta = 60℃ (Normally 20℃ is raised to 80℃)

Heating time Tm = 0.25 h

From efficiency η = 0.3 - Required amount of heat for the heater Q[kW] = (M × Hc × Ta) / (860 × Tm × η)

= (3 × 0.110 × 60) / (860 × 0.25 × 0.3)

= 0.307kW = 307W - Power density of heat generating section [W / cm²] = W / (3.14 × (D / 10) × (L / 10 - 1.5))

=310 / (3.14 × 0.8 × 30 - 1.5)

=4.3 W/cm²

→(2 ≦ 4.3 [W / cm²] ≦ 15), this can be produced.

Other Design Consideration

- The blade is placed diagonally to improve the cutting performance.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category