(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000225 Roller Cleaning Mechanism

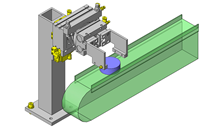

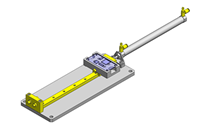

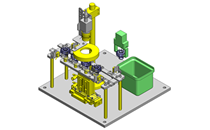

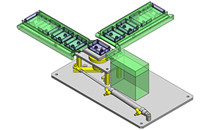

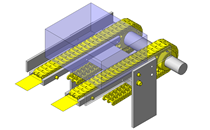

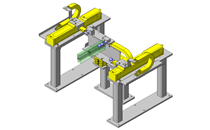

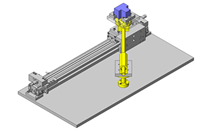

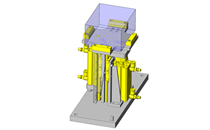

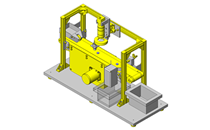

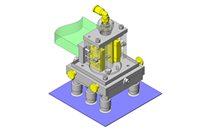

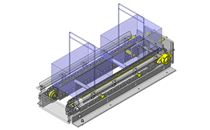

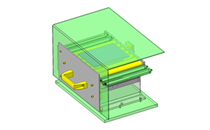

No.000225 Roller Cleaning Mechanism

29

29

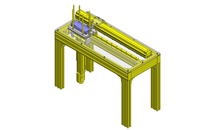

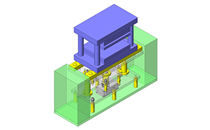

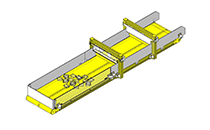

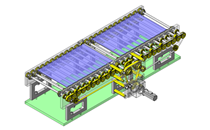

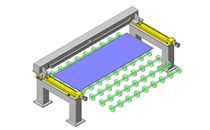

Glass substrate cleaning using a set of rollers.

Relevant category

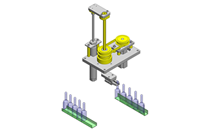

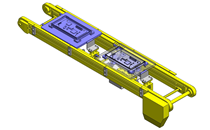

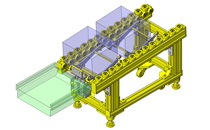

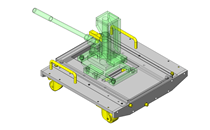

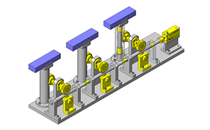

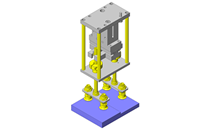

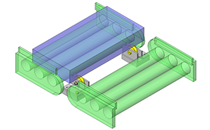

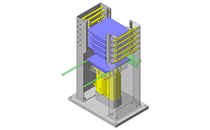

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

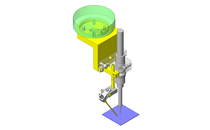

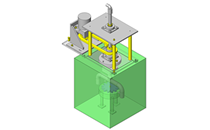

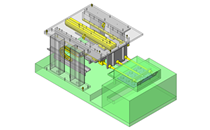

- Circuit board cleaning unit (height adjustable).

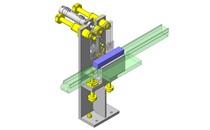

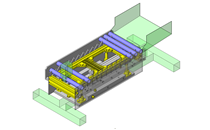

Points for use

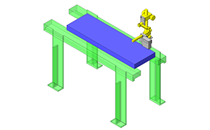

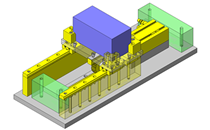

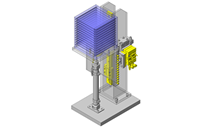

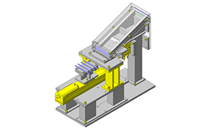

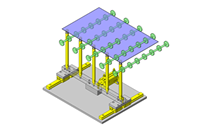

- For clean room environment.

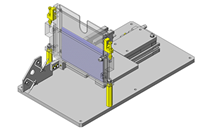

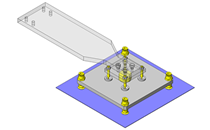

- A cover is added to protect equipment from splashing of dirt and cleaning agent.

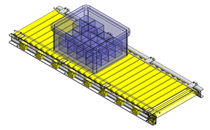

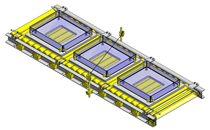

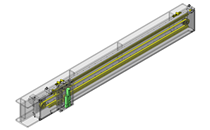

Target workpiece

- Glass circuit board: W 400 x D 500 x t 0.5mm

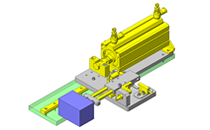

Design Specifications

Operating Conditions or Design Requirements

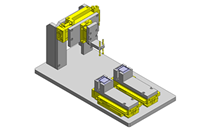

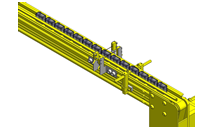

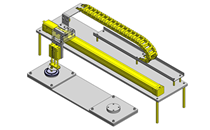

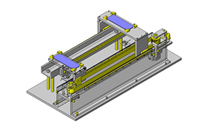

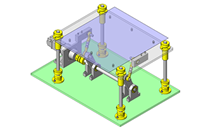

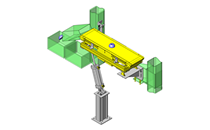

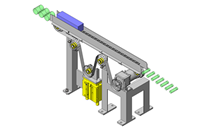

- Up and down adjustment stroke +/- 5mm

- External size: W 198 x D 1143 x H 753mm

Required Performance

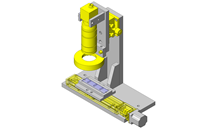

- Load of section for up and down: P = 300N

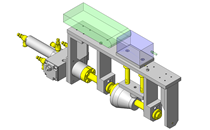

Selection Criteria for Main Components

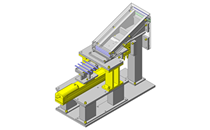

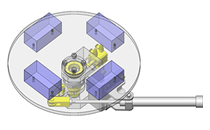

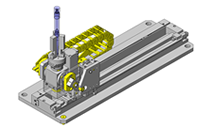

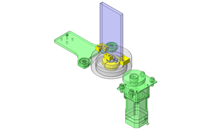

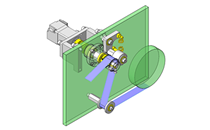

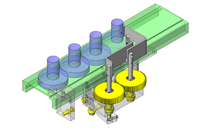

- Select the tilting angle of knob, screw and roller follower that are operable for up and down movement by turning the knob manually.

Design Evaluation

Verification of main components

- Required manual operation force and motor moment of inertia under operating conditions are verified.

- Condition values: Up and down section load P = 300N, tilting angle of roller follower section α = 6°, efficiency of M16 x 1.0 η = 0.08, lead of M16 x 1.0 L = 1, friction coefficient of linear guide μ = 0.003

- Force due to up and down section: Fs = P x sinα = 300 x sin6°= 300 x 0.1 = 30N

- Friction resistance force: Fa = μ x P = 0.003 x 300 = 0.9N

- Torque to turn knob: T = (FS + FA) x L/(2πη) = (30 + 0.9) x 1/(2π x 0.08) = 78N・mm

- The force required for turning knob manually is F = 78/40 = 2N≒0.2kg because of knob diameter: 40mm

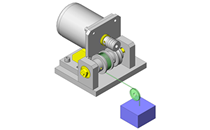

- Selection of Motor.

- Permissible load inertia of moment of motor: JM = 10 x 10-4kg・m²

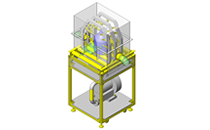

Other Design Consideration

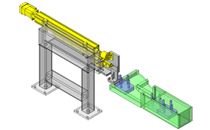

- The height adjustment mechanism of brush cleaning is connected by a front/back side shaft.

- Motor splash cover is easily removable to be cleaned or replaced.

- A protective cover is separately installed for mechanical elements such as the linear guide during cleaning (omitted in example image).

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category