(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000291 Magazine Transfer Mechanism

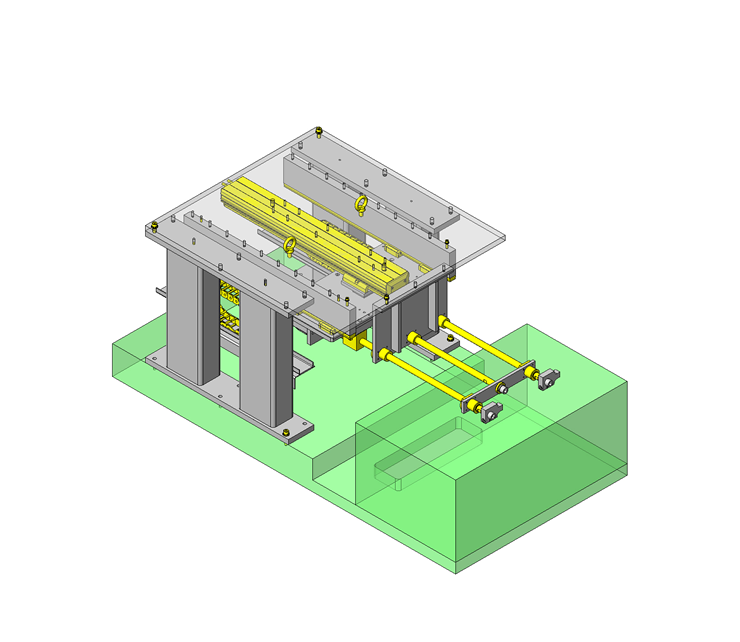

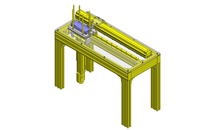

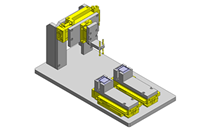

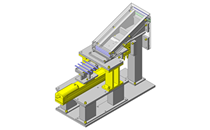

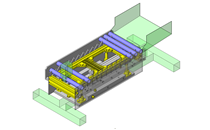

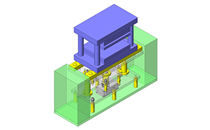

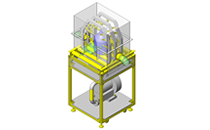

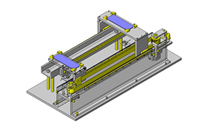

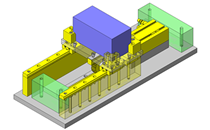

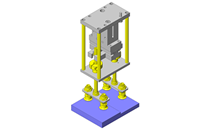

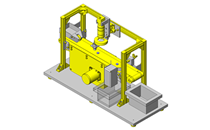

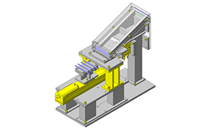

No.000291 Magazine Transfer Mechanism

37

37

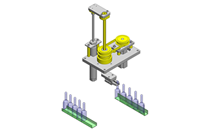

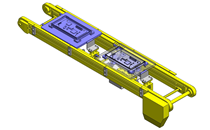

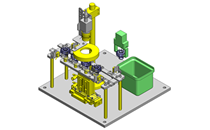

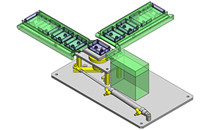

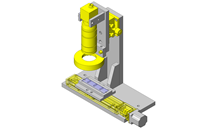

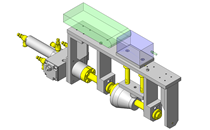

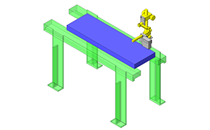

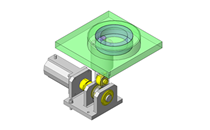

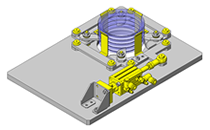

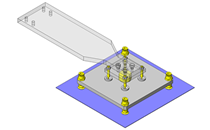

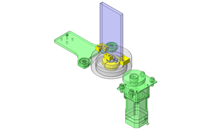

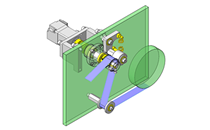

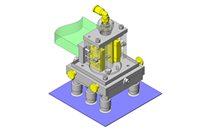

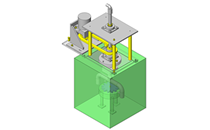

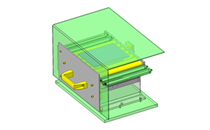

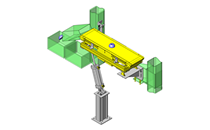

The rotary hand that pulls magazines out of the box.

Relevant category

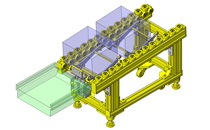

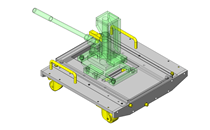

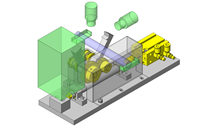

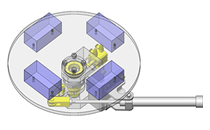

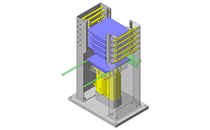

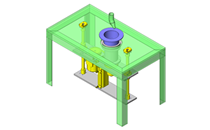

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

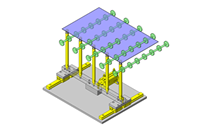

Application Overview

Purpose

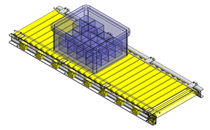

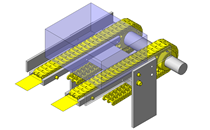

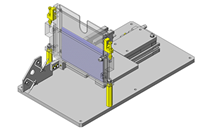

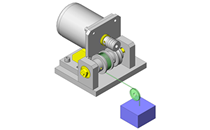

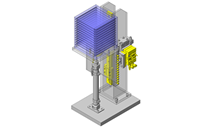

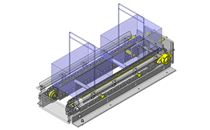

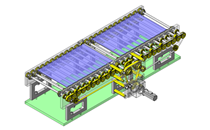

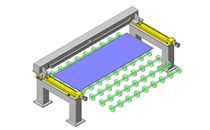

- A mechanism used to remove magazines from a box and transfer them to cutting operation.

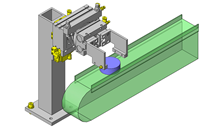

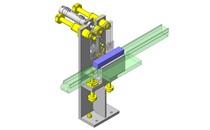

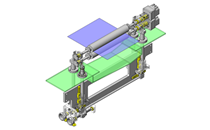

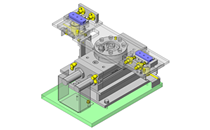

- The magazine box has limited access. The removal fingers are inserted in the horizontal position between the magazines and the box. Once they are in position, the fingers are rotated to the vertical position so they can engage the magazines.

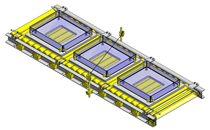

- Only one layer of magazine is pulled-out during one cycle.

Points for use

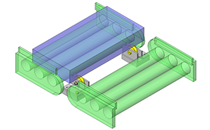

- The box used for transporting the magazines is only open on one side.

Target workpiece

- Small-part magazine

- External dimensions: W 280 x D 70 x H 23 mm

- Capacity: 0.22kg (including transporting parts: 0.33 kg)

Design Specifications

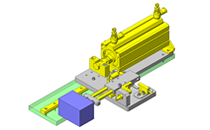

Operating Conditions or Design Requirements

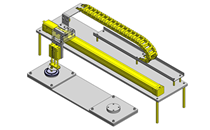

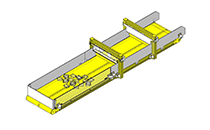

- External dimensions: W 600 x D 1005 x H 416 mm

- Pull-out stroke: 257 mm

Required Performance

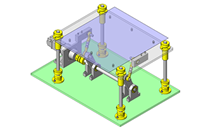

- Movable object weight: 12 kg

Workpiece weight: 0.33 x 3 = 0.99 kg

12+0.99=12.99kg

Selection criteria for Main Components

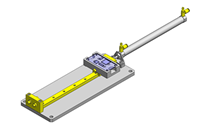

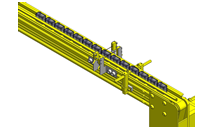

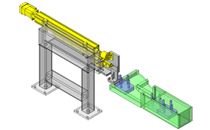

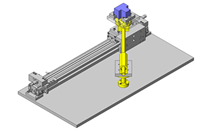

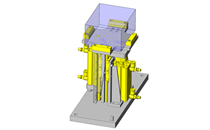

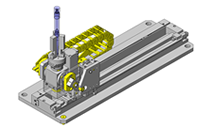

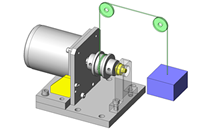

- Single axis robot

- Select one with a thrust of 127.3 N (12.99 kg) or more.

Design Evaluation

Verification of main components

- Verify that robot thrust exceeds required thrust.

- Single axis robot

- Thrust: 283 N (catalogue value)

- Required thrust: 12.99 (workpiece Capacity)×9.8=127.3 N<283 N

Other Design Consideration

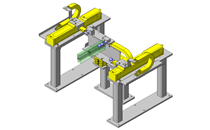

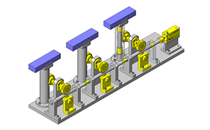

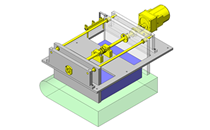

- To reduce the weight of the arms entering the box, hollow shafts are used.

- Three arms are used in the mechanism that removes the magazines. One is fixed and two are adjustable.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category