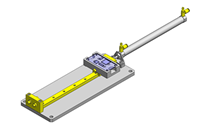

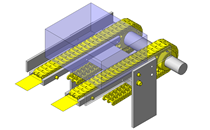

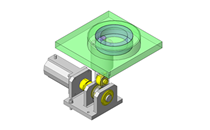

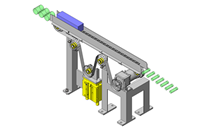

Rotary shaft

| Product name | Rotary Shafts - Straight |

| Part number | SSFHR6-35 |

| Features | g6 (ground), h7 (ground) and h9 (polished) are available. Please select based on your applications. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Can be used as a torque rotary shaft.

Back to page top

Available sizes

■Rotary Shafts - Straight

| O.D. tolerance | Material | Surface Treatment |

|

| h9 (Cold-drawn) | 1045 Carbon Steel | Black Oxide |

| Electroless Nickel Plating |

| 304 Stainless Steel | − |

| h7 (Ground) | 1045 Carbon Steel | Black Oxide |

| Electroless Nickel Plating |

| 304 Stainless Steel | − |

| g6 (Ground) | 1045 Carbon Steel | Black Oxide |

| Electroless Nickel Plating |

| 304 Stainless Steel | − |

4137 Alloy Steel

(Hardness: 30 - 35HRC) | Black Oxide |

| Electroless Nickel Plating |

■Sizes

| O.D. tolerance | Diameter | Tolerance | Length

(Configure in 0.1 mm increment) |

| h9 | φ3 | 0/-0.025 | 15.0 〜 150.0 |

| φ4 | 0/-0.030 | 15.0 〜 200.0 |

| φ5 | 15.0 〜 250.0 |

| φ6 | 20.0 〜 300.0 |

| φ8 | 0/-0.036 | 20.0 〜 400.0 |

| φ10 | 20.0 〜 500.0 |

| φ12 | 0/-0.043 | 30.0 〜 600.0 |

| φ15 | 30.0 〜 700.0 |

| φ20 | 0/−0.052 | 40.0 〜 800.0 |

| φ25 | 50.0 〜 800.0 |

| φ30 | 60.0 〜 800.0 |

| φ35 | 0/−0.062 | 70.0 〜 800.0 |

| φ40 | 80.0 〜 800.0 |

| φ50 | 100.0 〜 800.0 |

| h7 | φ6 | 0/−0.012 | 20.0 〜 300.0 |

| φ8 | 0/-0.015 | 20.0 〜 400.0 |

| φ10 | 20.0 〜 500.0 |

| φ12 | 0/-0.018 | 30.0 〜 600.0 |

| φ15 | 30.0 〜 700.0 |

| φ20 | 0/-0.021 | 40.0 〜 800.0 |

| φ25 | 50.0 〜 800.0 |

| φ30 | 60.0 〜 800.0 |

| φ35 | 0/-0.025 | 70.0 〜 800.0 |

| φ40 | 80.0 〜 800.0 |

| φ50 | 100.0 〜 800.0 |

| g6 | φ3 | −0.002/-0.008 | 15.0 〜 150.0 |

| φ4 | −0.004/-0.012 | 15.0 〜 200.0 |

| φ5 | 15.0 〜 250.0 |

| φ6 | 20.0 〜 300.0 |

| φ8 | −0.005/-0.014 | 20.0 〜 400.0 |

| φ10 | 20.0 〜 500.0 |

| φ12 | −0.006/-0.017 | 30.0 〜 600.0 |

| φ13 | 30.0 〜 600.0 |

| φ15 | 30.0 〜 700.0 |

| φ16 | 30.0 〜 800.0 |

| φ17 | 40.0 〜 800.0 |

| φ18 | 40.0 〜 800.0 |

| φ20 | −0.007/-0.020 | 40.0 〜 800.0 |

| φ22 | 40.0 〜 800.0 |

| φ25 | 50.0 〜 800.0 |

| φ30 | 60.0 〜 800.0 |

| φ35 | −0.009/-0.025 | 70.0 〜 800.0 |

| φ40 | 80.0 〜 800.0 |

| φ50 | 100.0 〜 800.0 |

* The size possible to select may vary slightly depending upon the materials. Please see the product pages for details.

Back to page top

Accuracy Info

■Accuracy of Rotary Shafts

| Diameter | Circularity M | Straightness |

| φ3~13 | 0.004 | 0.01/100 |

| φ14~20 | 0.005 |

| φ21~40 | 0.006 |

| φ41~50 | 0.007 |

■Length Tolerance

| Length | Dimension

Tolerance |

| over | or Less |

| 14 | 30 | ±0.2 |

| 30 | 120 | ±0.3 |

| 120 | 400 | ±0.5 |

| 400 | 800 | ±0.8 |

Back to page top

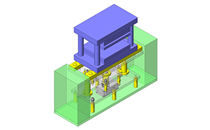

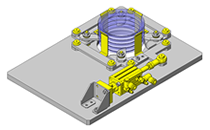

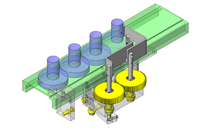

Small Ball Bearings

| Product name | Small Deep Groove Ball Bearings - Double Shielded with Flanged |

| Part number | FL696ZZ |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Suitable for supporting radial motion.

Back to page top

Available sizes

■Small deep groove ball bearings with flange, double shielded

Material: 52100 Bearing Steel

| (Name No.) | Shaft Bore Dia. | Outer Cylinder O.D. | Flange O.D. | Overall thickness | Flange

height |

|

| FL682ZZ | φ2 | φ5 | φ6.1 | 2.3 | 0.6 |

| FL692ZZ | φ6 | φ7.5 | 3 | 0.8 |

| FL682AZZ | φ2.5 | φ6 | φ7.1 | 2.6 | 0.8 |

| FL692AZZ | φ7 | φ8.5 | 3.5 | 0.9 |

| FL673ZZ | φ3 | φ6 | φ7.2 | 2.5 | 0.6 |

| FL683ZZ | φ7 | φ8.1 | 3 | 0.8 |

| FL693ZZ | φ8 | φ9.5 | 4 | 0.9 |

| FL603ZZ | φ9 | φ10.5 | 5 | 1 |

| FL623ZZ | φ10 | φ11.5 | 4 | 1 |

| FL674ZZ | φ4 | φ7 | φ8.2 | 2.5 | 0.6 |

| FL684ZZ | φ9 | φ10.3 | 4 | 1 |

| FL694ZZ | φ11 | φ12.5 | 1 |

| FL604ZZ | φ12 | φ13.5 |

| FL624ZZ | φ13 | φ15 | 5 |

| FL675ZZ | φ5 | φ8 | φ9.2 | 2.5 | 0.6 |

| FL685ZZ | φ11 | φ12.5 | 5 | 1 |

| FL695ZZ | φ13 | φ15 | 4 |

| FL605ZZ | φ14 | φ16 | 5 |

| FL625ZZ | φ16 | φ18 | 5 |

| FL676ZZ | φ6 | φ10 | φ11.2 | 3 | 0.6 |

| FL686ZZ | φ13 | φ15 | 5 | 1.1 |

| FL696ZZ | φ15 | φ17 | 1.2 |

| FL606ZZ | φ17 | φ19 | 6 |

| FL626ZZ | φ19 | φ22 | 6 | 1.5 |

| FL678ZZ | φ8 | φ12 | φ13.6 | 3.5 | 0.8 |

| FL688ZZ | φ16 | φ18 | 5 | 1.1 |

| FL698ZZ | φ19 | φ22 | 6 | 1.5 |

| FL608ZZ | φ22 | φ25 | 7 |

| FL6700ZZ | φ10 | φ15 | φ16.5 | 4 | 0.8 |

| FL6800ZZ | φ19 | φ21 | 5 | 1 |

| FL6900ZZ | φ22 | φ25 | 6 | 1.5 |

| FL6701ZZ | φ12 | φ18 | φ19.5 | 4 | 0.8 |

| FL6801ZZ | φ21 | φ23 | 5 | 1.1 |

| FL6901ZZ | φ24 | φ26.5 | 6 | 1.5 |

| FL6702ZZ | φ15 | φ21 | φ22.5 | 4 | 0.8 |

| FL6802ZZ | φ24 | φ26 | 5 | 1.1 |

| FL6902ZZ | φ28 | φ30.5 | 7 | 1.5 |

| FL6703ZZ | φ17 | φ23 | φ24.5 | 4 | 0.8 |

| FL6803ZZ | φ26 | φ28 | 5 | 1.1 |

| FL6903ZZ | φ30 | φ32.5 | 7 | 1.5 |

| FL6704ZZ | φ20 | φ27 | φ28.5 | 4 | 0.8 |

| FL6804ZZ | φ32 | φ35 | 7 | 1.5 |

| FL6904ZZ | φ37 | φ40 | 9 | 2 |

| FL6805ZZ | φ25 | φ37 | φ40 | 7 | 1.5 |

| FL6905ZZ | φ42 | φ45 | 9 | 2 |

* Please see the product pages for recommended dimensions of the mating shaft.

Back to page top

Performance info.

■Load info of Small deep groove ball bearings with flange, double shielded

| (Name No.) | Shaft Bore Dia. | Outer Cylinder O.D. | Basic Load Rating | Allowable Rotational

Speed rpm

(Reference) |

| Cr(Dynamic)N | Cor(Static)N |

| FL682ZZ | φ2 | φ5 | 169 | 50 | 85000 |

| FL692ZZ | φ6 | 330 | 98 | 75000 |

| FL682AZZ | φ2.5 | φ6 | 208 | 74 | 71000 |

| FL692AZZ | φ7 | 385 | 127 | 63000 |

| FL673ZZ | φ3 | φ6 | 208 | 74 | 71000 |

| FL683ZZ | φ7 | 390 | 130 | 63000 |

| FL693ZZ | φ8 | 560 | 179 | 60000 |

| FL603ZZ | φ9 | 570 | 187 | 56000 |

| FL623ZZ | φ10 | 630 | 218 | 50000 |

| FL674ZZ | φ4 | φ7 | 222 | 88 | 60000 |

| FL684ZZ | φ9 | 640 | 224 | 53000 |

| FL694ZZ | φ11 | 715 | 276 | 48000 |

| FL604ZZ | φ12 | 957 | 345 | 48000 |

| FL624ZZ | φ13 | 1300 | 485 | 40000 |

| FL675ZZ | φ5 | φ8 | 217 | 91 | 53000 |

| FL685ZZ | φ11 | 715 | 281 | 45000 |

| FL695ZZ | φ13 | 1080 | 430 | 43000 |

| FL605ZZ | φ14 | 1330 | 505 | 40000 |

| FL625ZZ | φ16 | 1729 | 670 | 36000 |

| FL676ZZ | φ6 | φ10 | 465 | 196 | 45000 |

| FL686ZZ | φ13 | 1080 | 440 | 40000 |

| FL696ZZ | φ15 | 1350 | 530 | 40000 |

| FL606ZZ | φ17 | 2190 | 835 | 38000 |

| FL626ZZ | φ19 | 2336 | 885 | 32000 |

| FL678ZZ | φ8 | φ12 | 515 | 252 | 40000 |

| FL688ZZ | φ16 | 1610 | 710 | 36000 |

| FL698ZZ | φ19 | 1990 | 865 | 36000 |

| FL608ZZ | φ22 | 3350 | 1400 | 34000 |

| FL6700ZZ | φ10 | φ15 | 855 | 435 | 15000 |

| FL6800ZZ | φ19 | 1716 | 840 | 37000 |

| FL6900ZZ | φ22 | 2695 | 1273 | 34000 |

| FL6701ZZ | φ12 | φ18 | 926 | 530 | 13000 |

| FL6801ZZ | φ21 | 1915 | 1041 | 33000 |

| FL6901ZZ | φ24 | 2886 | 1466 | 31000 |

| FL6702ZZ | φ15 | φ21 | 937 | 582 | 11000 |

| FL6802ZZ | φ24 | 2073 | 1253 | 28000 |

| FL6902ZZ | φ28 | 4321 | 2259 | 26000 |

| FL6703ZZ | φ17 | φ23 | 1000 | 658 | 9500 |

| FL6803ZZ | φ26 | 2233 | 1456 | 26000 |

| FL6903ZZ | φ30 | 4588 | 2565 | 23000 |

| FL6704ZZ | φ20 | φ27 | 1041 | 729 | 8500 |

| FL6804ZZ | φ32 | 4015 | 2462 | 21000 |

| FL6904ZZ | φ37 | 6381 | 3682 | 19000 |

| FL6805ZZ | φ25 | φ37 | 4303 | 2932 | 18000 |

| FL6905ZZ | φ42 | 7001 | 4540 | 16000 |

Back to page top

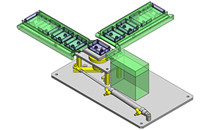

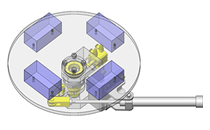

Gussets

| Product name | Gussets- Tapped Holes, Standard Holes Position, Standard Perpendicularity Type |

| Part number | RBBW30-30-6 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Suitable as L-shaped reinforcement

Back to page top

Available sizes

■Rib - Tapped Hole Fixed Dimensions

| Precision Type | Material | Surface Treatment |

Standard Grade

(Perpendicularity: 0.05/100)

/

Precision Grade

(Perpendicularity: 0.02/100) | 1018 Carbon Steel | − |

| Black Oxide |

| Electroless Nickel Plating |

| 5052 Aluminum Alloy | − |

| Clear Anodize |

| Black Anodize |

| 304 Stainless Steel | − |

■Sizes and Dimensions

| Precision Type | Short side | Long side | Thickness/Tapped Hole Dia. | Tapped

Hole Depth |

| 30 | 40 | 50 | 60 | 80 | 100 | 1018 Carbon Steel / 304 Stainless Steel | 5052 Aluminum Alloy |

| t6 | t9 | t12 | t16 | t6 | t10 | t12 | t16 |

Standard Grade

(Perpendicularity: 0.05/100)

/

Precision Grade

(Perpendicularity: 0.02/100) | 20 | ○ | ○ | ○ | ○ | ○ | | M3 | | | | M3 | | | | Diameter x 1.5 |

| 30 | ○ | | | | | | M3 | | M6 | | M3 | | M6 | |

| ○ | ○ | ○ | ○ | ○ | | M5 | M6 | | | M5 | M6 | |

| 40 | | ○ | ○ | ○ | ○ | ○ | | M5 | M6 | | | M5 | M6 | |

| | | | | | | | M6 | M8 | | | M6 | M8 |

| 50 | | | ○ | ○ | ○ | ○ | | M5 | M6 | | | M5 | M6 | |

| | | | | | | | M6 | M8 | | | M6 | M8 |

| 60 | | | | ○ | ○ | ○ | | M5 | M6 | | | M5 | M6 | |

| | | | | | | | M6 | M8 | | | M6 | M8 |

| 80 | | | | | ○ | ○ | | M5 | M6 | M8 | | M5 | M6 | M8 |

| | | | | | | | M6 | M8 | | | M6 | M8 |

| ## | | | | | | ○ | | M5 | M6 | M8 | | M5 | M6 | M8 |

| | | | | | | | M6 | M8 | | | M6 | M8 |

Back to page top

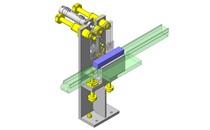

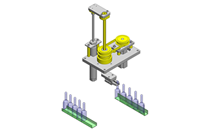

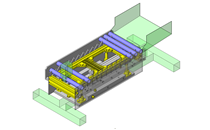

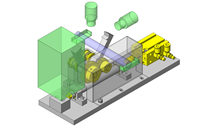

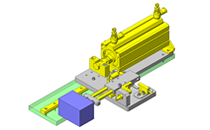

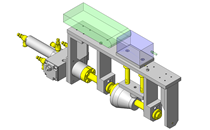

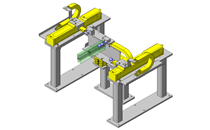

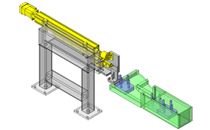

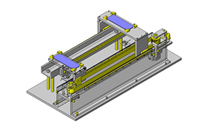

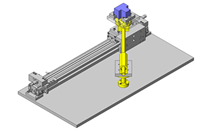

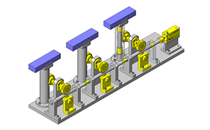

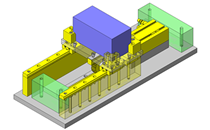

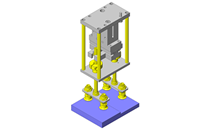

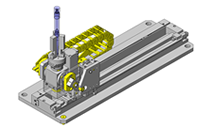

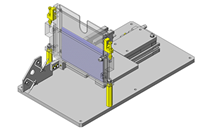

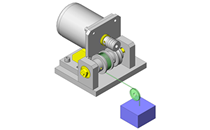

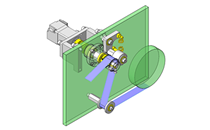

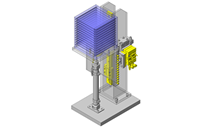

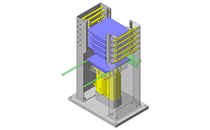

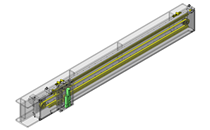

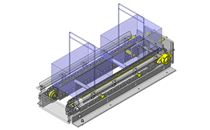

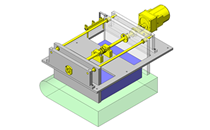

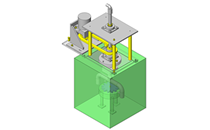

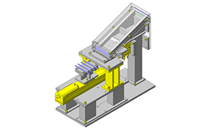

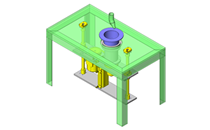

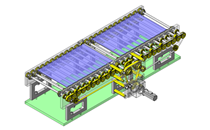

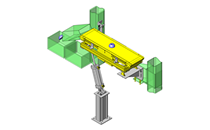

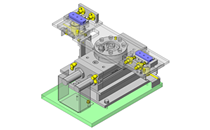

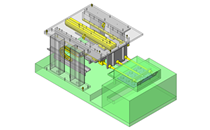

IDEA NOTE Reducing moment generated on the motor shaft.

Wire winding drum is fixed on each end: the motor axis and shaft end supported by bearing.