(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000174 Transfer Mechanism

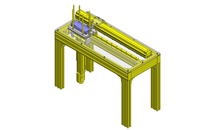

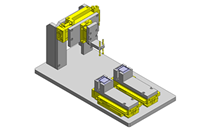

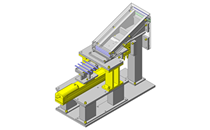

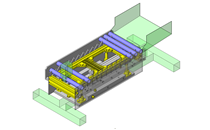

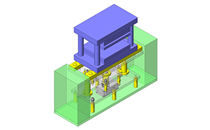

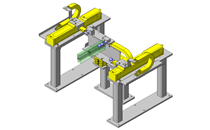

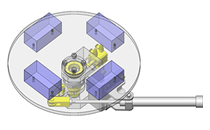

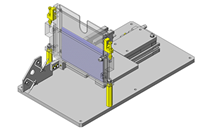

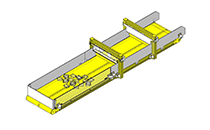

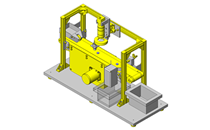

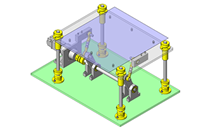

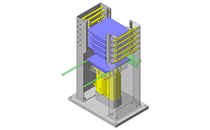

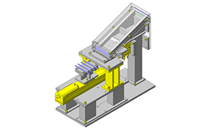

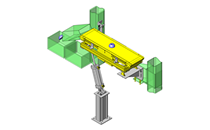

No.000174 Transfer Mechanism

22

22

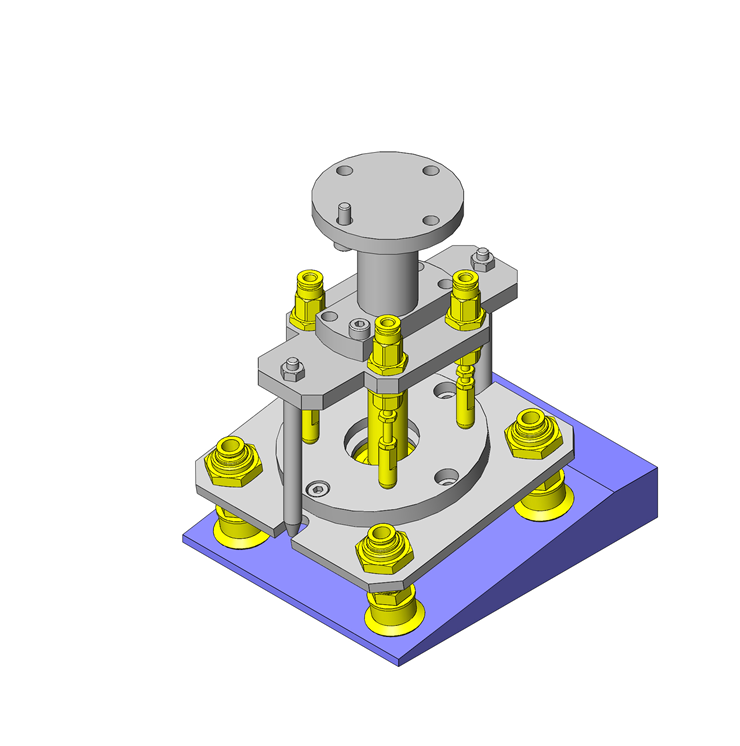

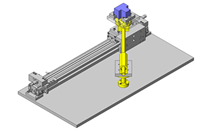

Transporting an object while retaining the angle of suction

Relevant category

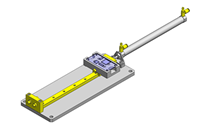

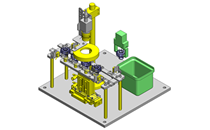

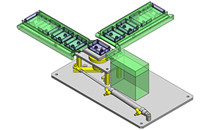

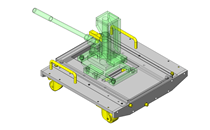

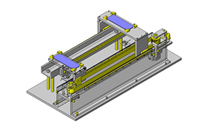

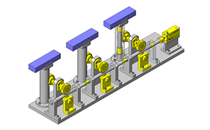

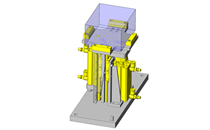

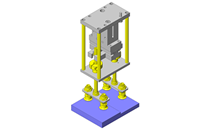

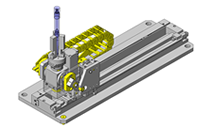

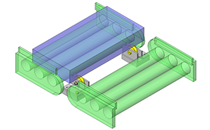

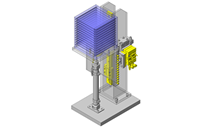

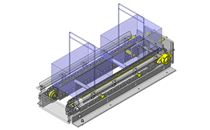

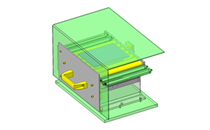

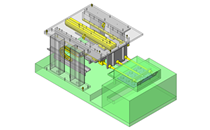

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

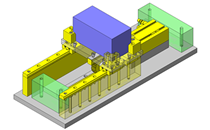

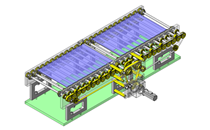

Application Overview

Purpose

- Purpose

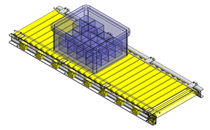

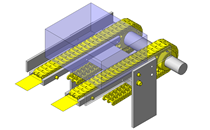

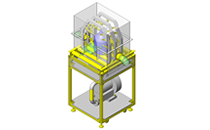

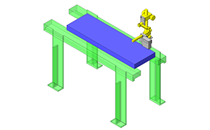

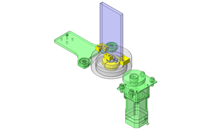

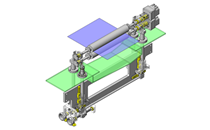

- To utilize suction cups for transporting different shape plastic cases while maintaining orientation of the workpiece.

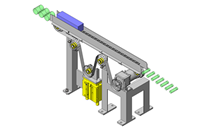

- Operation

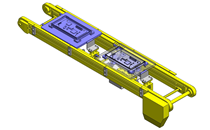

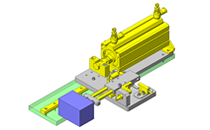

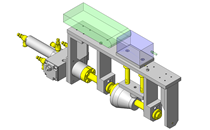

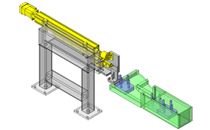

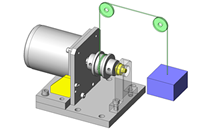

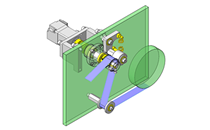

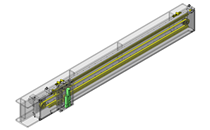

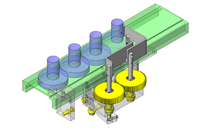

- The spherical bearings and air cylinder allow the suction cups to be tilted, so they are flush against the workpiece.

- By using regulators and electromagnetic valves, the floating pressure can be adjusted during the transfer process.

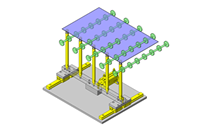

Points for use

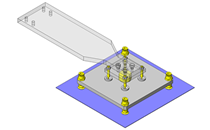

- The angle of suction cups can be retained by locking the air circuit.

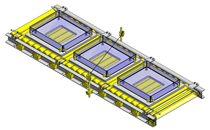

Target workpiece

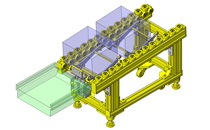

- Shape: Plastic case

- Size: W 100 x D 120 x H 20 (max) mm

- Weight:0.3kg

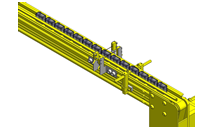

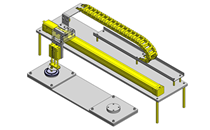

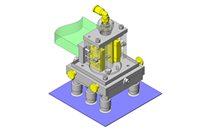

Design Specifications

Operating Conditions or Design Requirements

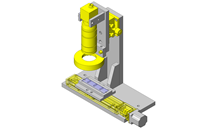

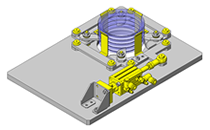

- Spherical bearing deviation angle 13°

- Cylinder stroke: 8.3 + 3 = 11.3 mm

- Output 11.3 x 70% = 7.91 N・m (air pressure 0.4 MPa)

- Spring force at 15 mm stroke 3.66 N

7.91-3.66=4.25N - External size: 96 x 100 x 130 mm

Required Performance

- Allowable weight: 1.38 kg

Selection Criteria for Main Components

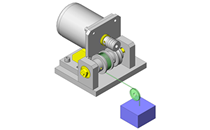

- Air Cylinder

- Output at least 3.76 N at stroke of 15 mm or more.

Design Evaluation

Verification of main components

- Verify the air cylinder output

Force conditional values at maximum tilt of the workpiece

Workpiece weight: M=0.3kg

Gravitational acceleration: g = 9.8m/s²

Workpiece maximum tilt: θ₁=13°

Distance between rotation center and workpiece center of

gravity: L₁ = 25mm = 0.025m

Distance between rotation center and cylinder mounting: L₂ = 18mm = 0.018m

Cylinder output: F = 4.25N

Suction cup diameter:d=φ20

Vacuum level: p = 70 -kPa = 0.07 -MPa

Safety factor at suction: S=4 - Air cylinder selection

- Moment by the workpiece:M₁

M₁=M×g×sinθ₁×L₁=0.3×9.8×sin13°×0.025=0.017N・m

Force F₂ applied to the cylinder by moment M₁

M₁ = F₂' x L₂ = F₂ x cosθ₁ x L₂ Thus, we have the following:

F₂=M₁/(cosθ₁×L₂) =0.017/(cos13°×0.018)=0.017/(0.97×0.018)

=0.97N

Thus, select an air cylinder with cylinder output of F. - Check the load by the selected cylinder.

Moment M₂ by the air cylinder at maximum tilt

M₂=F'×L₂=F×cosθ₁×L₂

=4.25×cos13°×0.018=4.25×0.97×0.018=0.075N・m

Therefore, M₂>M₁. Thus, meeting the condition. - Check the suction force.

Vacuum level: p = 70 -kPa = 0.07 -MPa, cup diameter: d = φ 20mm

Safety factor at suction: S = 4, number of cups: n = 4

Suction force:W=π/4×d²×p×1/S×n=π/4×20²×0.07×1/4×4=22N

Therefore, W > M x g ⇒ 22N > 3N Thus, the suction force satisfies the condition.

Other Design Consideration

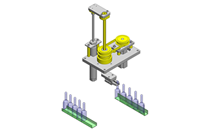

- By using a guide pin with spherical bearing, floating suction hand can be tilted in a desired direction to grip the workpiece.

- The suction hand is free floating after the workpiece is released. Therefore, it is recommended to use the four cylinders to lock the hand in place when it is not gripping a workpiece.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category