(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000308 Sheet Forming Machine

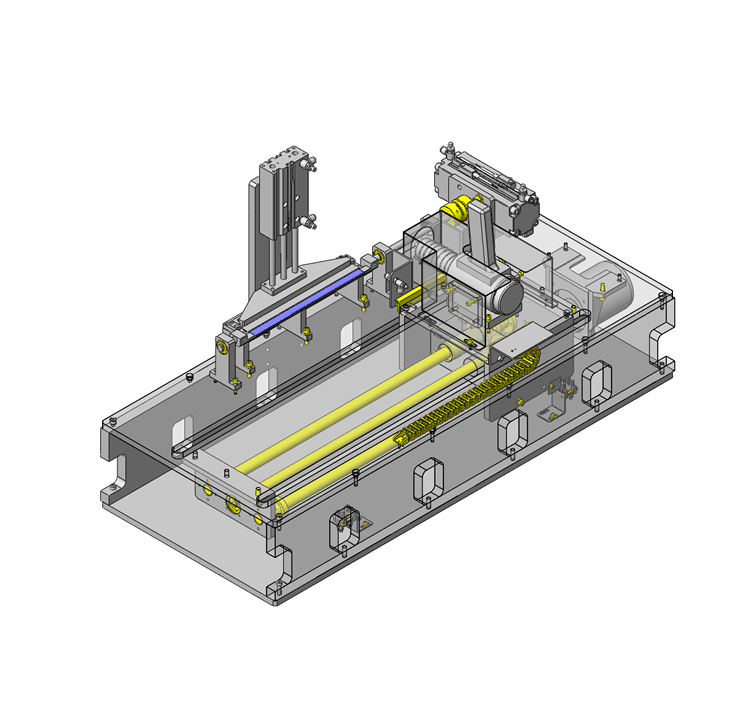

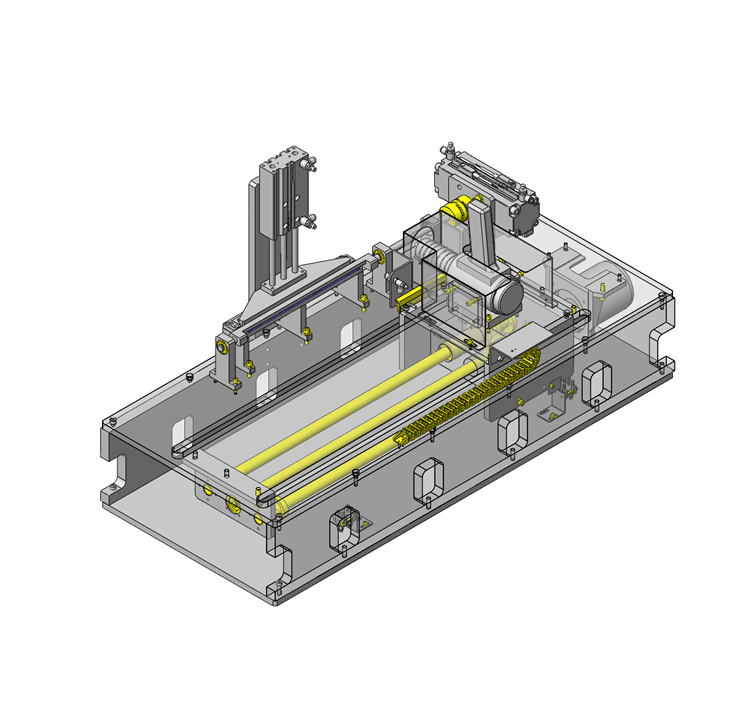

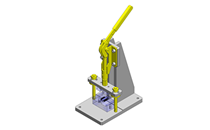

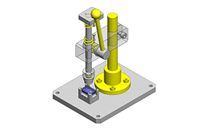

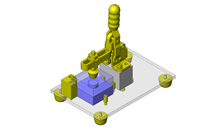

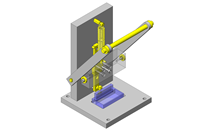

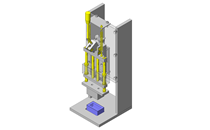

No.000308 Sheet Forming Machine

149

149

Simplified bending/forming machine

Relevant category

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- To roll the end portion of a resin sheet into a U shape.

Points for use

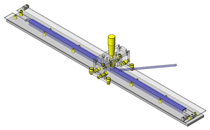

- After the operator sets a resin sheet on the machining table, pressing the start button (1) clamps the resin sheet, (2) rotates the roll bar by 180° (bending the resin sheet into a U shape), (3) starts leftward travel of the heater at 120mm/2.3 sec, (4) activates the heater ON timer, (5) moves the heater to the right end of the resin sheet, (6) performs heating travel on the resin sheet at 260mm/4.9 sec, (7) makes the heater travel at 20mm/0.4 sec, (8) stops the heater at the left end (stroke end), (9) starts rightward travel of the heater, (10) performs heating travel on the resin sheet, (11) turns the heater OFF (by timer operation), and (12) stops the heater at the right end. Optimum conditions such as heating and air blow performed in combination, heater stop during rightward travel, and air blow travel should be determined through trial and error.

Target workpiece

- Shape: resin film

- Size: 260 x 45 x t0.7mm

Design Specifications

Operating Conditions or Design Requirements

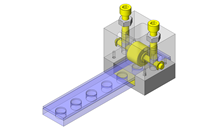

- Sheet clamp stroke: 100mm

- Sheet rotation angle: 180°

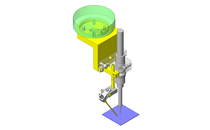

- Heater: 1kw

- Heater travel unit stroke: 474mm

- Travel time: 7.5sec (variable speed)

- Outer dimensions: W987 x D455 x H514mm

Required Performance

- Positioning accuracy: ±0.2mm

Selection Criteria for Main Components

- Selection of heater

- Heating temperature of 250°±30° adjustment by room-temperature compressed air blow (through trials and errors)

The hot air blow ON/OFF timing is determined by the timer activated during travel.

Heating time 15sec (in reciprocating operation)

- Heating temperature of 250°±30° adjustment by room-temperature compressed air blow (through trials and errors)

Design Evaluation

Verification of main components

- A motor with a torque that can withstand the load is selected.

- Load of table unit: M = 7kg

Lead of lead screw: L = 0.004m

Drive section efficiency: η = 0.26

Friction coefficient of guide: μ = 0.15

Motor startup torque Tm = 0.28N·m

Rotation speed range of speed controller motor: n = 90 to 1400rpm

Motor rotation speed: N = 60 x V/L

= 60 x 53/4

≒ 800rpm

Load: F = μ x M x 9.8

= 0.15 x 7 x 9.8

= 10.3N

Load torque: T = LF/2πη

= 10.3 x 0.004/2 x 3.14 x 0.26

= 0.026N・m

Therefore, T < TM

- Load of table unit: M = 7kg

Other Design Consideration

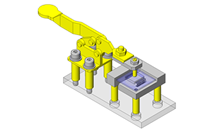

- A cylinder with a guide is used for sheet clamping to reduce cost.

- For sheet rotation, a stopper is provided on the rotary actuator to make the bending amount adjustable.

- The heater is fixed with screw clamps for facilitating replacement, and as its traveling accuracy and stopping accuracy specifications are rough, lead screws and a small-size speed controller motor are used.

- The temperature of hot air is 450°C at the heater air blow port. To adjust the temperature, it is also equipped with an air blow nozzle.

- The heating time should be determined through trial and error. The heating time is around 15 seconds (reciprocation).

Explore Similar Application Examples

Page

-

/

-