(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000013 Long Workpiece Holding Fixture

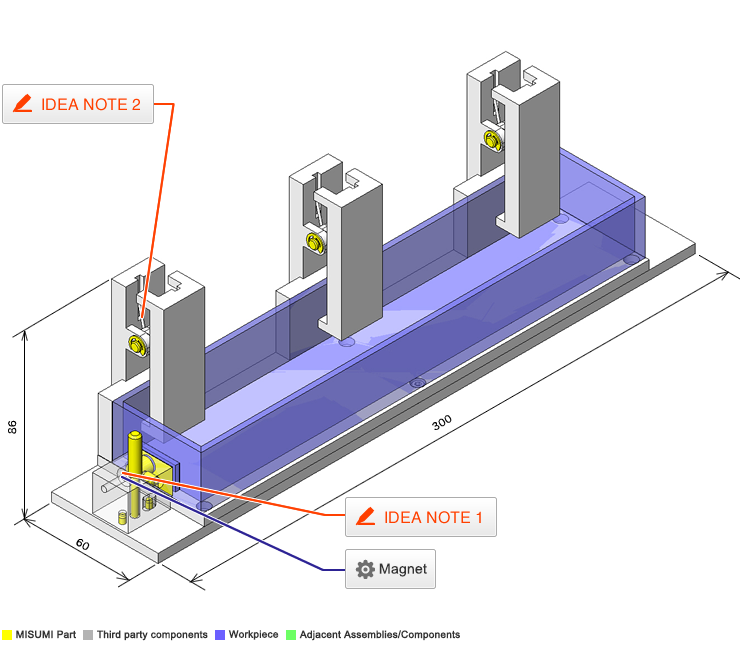

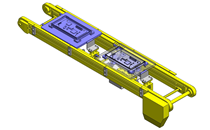

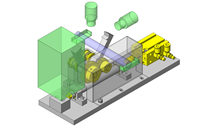

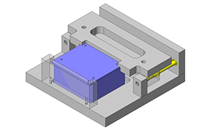

No.000013 Long Workpiece Holding Fixture

34

34

Magnetic and physical workpiece clamp.

Relevant category

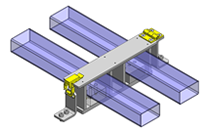

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

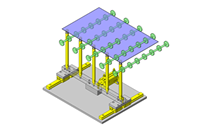

- Clamping mechanism which utilizes magnets as well as clips.

- Each clamp is separated allowing multiple points of contact.

Points for use

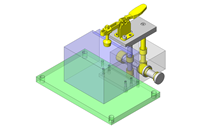

- The magnet locates the workpiece, and the clips hold it in place.

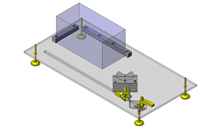

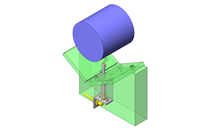

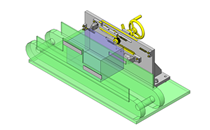

Target workpiece

- Long magnetic objects.

Dims: W50 x D150 x H30, t3

Design Specifications

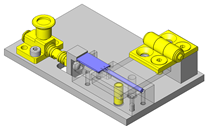

Operating Conditions or Design Requirements

- External dims.: W300 x D60 x H86

Required Performance

- Spring load: 10.23N (Unclamped)

8.26N(Workpiece clamped)

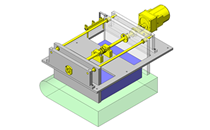

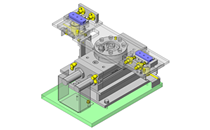

Selection Criteria for Main Components

- Clamps

- Spring with low constant is selected in order to reduce the operation efforts.

- Magnet

- Select a magnet with attraction force appropriate for the application.

- For this example, springs with constant : 2.44N・mm/deg. is selected.

Design Evaluation

Verification of main components

- Select a spring appropriate for the application.

- Spring load

- Calculation formula: Reaction force F = k x θ / l

Spring constant (k): 2.44 mm/deg

Max. operational angle (θ): 78

Load point distance from the coil center (I): 18.6mm

- Calculation formula: Reaction force F = k x θ / l

- Clamp released

- Spring. operational angle (θ): 78°

F = 2.44 × 78 / 18.6 = 10.23 N

- Spring. operational angle (θ): 78°

- Workpiece clamp

- Spring. operational angle (θ): 63°

F = 2.44 × 63 / 18.6 = 8.26 N

- Spring. operational angle (θ): 63°

Other Design Consideration

- Magnetic attraction force can be adjusted by magnet size and position.

- Select a torsional spring that makes the clip easily operational.

- Provide a magnet block and fixing pins on the right hand side to accommodate different workpieces.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category