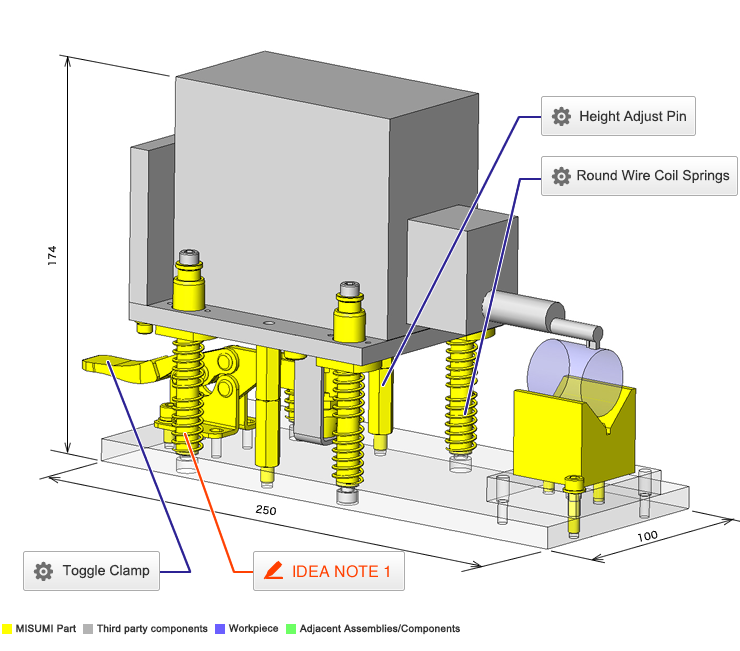

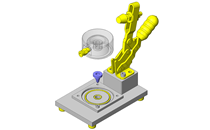

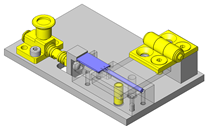

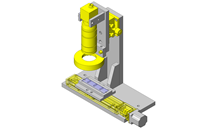

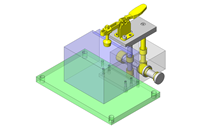

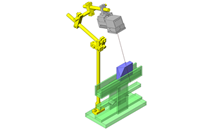

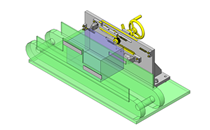

Toggle Clamp

| Product name | Toggle Clamps -Horizontal Handle- |

| Part number | MC01-3 |

| Features | Hold Down, Flange Base Type. Low Profile-designed. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Improves workability with a single lever action

Back to page top

Available sizes

Toggle Clamps -Horizontal Handle-

| Main body material | 1018 Carbon Steel | 304 Stainless Steel |

| Surface treatment | Trivalent chromate | - |

| Clamping force(N) | 264.6 | 264.6 | 400 | 882 | 2352 | 264.6 | 264.6 | 882 | 2352 |

| Weight(g) | 30 | 35 | 60 | 130 | 265 | 30 | 35 | 130 | 265 |

| Arm open/close angle | 90° | 90° | 90° | 85° | 90° | 90° | 90° | 85° | 90° |

| Handle open/close angle | 75° | 75° | 75° | 73° | 65° | 75° | 75° | 73° | 65° |

| Overall width | 23.8 | 23.8 | 23.8 | 36 | 35 | 23.8 | 23.8 | 36 | 35 |

| Overall height(Clampled) | 17.3 | 17.3 | 34.6 | 37.8 | 47.6 | 17.3 | 17.3 | 37.8 | 47.6 |

| Overall height(Unclamped) | 48.3 | 48.3 | 78 | 96.8 | 110.2 | 48.3 | 48.3 | 96.8 | 110.2 |

| Overall length (Clamped) | 71 | 69.1 | 100.6 | 143.5 | 173 | 71 | 69.1 | 143.5 | 173 |

| Clamp position | Fixed | Variable | Variable | Variable | Variable | Fixed | Variable | Variable | Variable |

| Accessory | Nylon Bolt | Bolt with rubber

Material: NBR

Hardness: Shore A70 | Stainless steel bolt |

* Please see the product pages for shape details and dimensions.

Back to page top

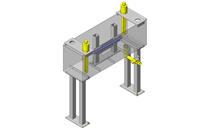

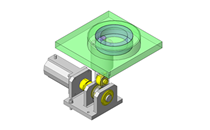

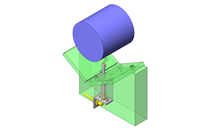

Round Wire Coil Springs

| Product name | Round Wire Springs -Spring Constant 0.5~1.0 N/mm- |

| Part number | WL14-65 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Used to raise the measurement section when the toggle clamp is released.

Back to page top

Available sizes

■Round Wire Springs -Spring Constant 0.5~1.0 N/mm-

Deflection

(Free length ratio) | Material | O.D.

range | Free length

range |

| Spring Steel (ASTM A228) | 304 Stainless Steel |

| 75% | ○ | ○ | φ3~16 | 5~70 |

| 60% | ○ | ○ | φ3~27 | 5~90 |

| 45% | ○ | ○ | φ3~27 | 5~90 |

| 40% | ○ | ○ | φ2~27 | 5~100 |

| 40% | ○ | ○ | φ3~27 | 5~80 |

| 35% | ○ | ○ | φ3~27 | 5~100 |

| 30% | ○ | ○ | φ4~27 | 5~100 |

| 25% | ○ | ○ | φ3~27 | 5~100 |

■Sizes and Dimensions

| O.D. | Free length | Coil wire DIA. | Solid length | Max. deflection | Load(N) |

| φ12 | 10 | φ0.8 | 4.8 | 4 | 4 |

| 15 | φ0.9 | 7.2 | 6 | 5.9 |

| 20 | φ0.9 | 7.2 | 8 | 7.8 |

| 25 | φ0.9 | 7.2 | 10 | 9.8 |

| 30 | φ1 | 10.5 | 12 | 11.8 |

| 35 | φ1 | 10.5 | 14 | 13.7 |

| 40 | φ1 | 10.5 | 16 | 15.7 |

| 45 | φ1.1 | 15.4 | 18 | 17.7 |

| 50 | φ1.1 | 15.4 | 20 | 19.6 |

| 55 | φ1.1 | 15.4 | 22 | 21.6 |

| 60 | φ1.2 | 22.8 | 24 | 23.5 |

| 65 | φ1.2 | 22.8 | 26 | 25.5 |

| 70 | φ1.2 | 22.8 | 28 | 27.5 |

| 80 | φ1.3 | 34.5 | 32 | 31.4 |

| φ13 | 10 | φ0.85 | 5.1 | 4 | 4 |

| 15 | φ0.9 | 6.3 | 6 | 5.9 |

| 20 | φ1 | 8.7 | 8 | 7.8 |

| 25 | φ1 | 8.7 | 10 | 9.8 |

| 30 | φ1.1 | 13.2 | 12 | 11.8 |

| 35 | φ1.1 | 13.2 | 14 | 13.7 |

| 40 | φ1.1 | 13.2 | 16 | 15.7 |

| 45 | φ1.1 | 13.2 | 18 | 17.7 |

| 50 | φ1.1 | 13.2 | 20 | 19.6 |

| 55 | φ1.1 | 13.2 | 22 | 21.6 |

| 60 | φ1.1 | 13.2 | 24 | 23.5 |

| 65 | φ1.2 | 18.6 | 26 | 25.5 |

| 70 | φ1.2 | 18.6 | 28 | 27.5 |

| 80 | φ1.4 | 37.8 | 32 | 31.4 |

| 90 | φ1.4 | 37.8 | 36 | 35.3 |

| φ14 | 15 | φ1 | 7.5 | 6 | 5.9 |

| 20 | φ1 | 7.5 | 8 | 7.8 |

| 25 | φ1 | 7.5 | 10 | 9.8 |

| 30 | φ1.1 | 11 | 12 | 11.8 |

| 35 | φ1.1 | 11 | 14 | 13.7 |

| 40 | φ1.1 | 11 | 16 | 15.7 |

| 45 | φ1.2 | 15.6 | 18 | 17.7 |

| 50 | φ1.2 | 15.6 | 20 | 19.6 |

| 55 | φ1.2 | 15.6 | 22 | 21.6 |

| 60 | φ1.2 | 15.6 | 24 | 23.5 |

| 65 | φ1.3 | 22.1 | 26 | 25.5 |

| 70 | φ1.3 | 22.1 | 28 | 27.5 |

| 80 | φ1.3 | 22.1 | 32 | 31.4 |

| 90 | φ1.5 | 43.5 | 36 | 35.3 |

| φ16 | 15 | φ1.1 | 8.2 | 6 | 5.9 |

| 20 | φ1.1 | 8.2 | 8 | 7.8 |

| 25 | φ1.2 | 10 | 10 | 9.8 |

| 30 | φ1.2 | 10 | 12 | 11.8 |

| 35 | φ1.2 | 10 | 14 | 13.7 |

| 40 | φ1.2 | 10 | 16 | 15.7 |

| 45 | φ1.4 | 21 | 18 | 17.7 |

| 50 | φ1.4 | 21 | 20 | 19.6 |

| 55 | φ1.4 | 21 | 22 | 21.6 |

| 60 | φ1.4 | 21 | 24 | 23.5 |

| 65 | φ1.5 | 29.7 | 26 | 25.5 |

| 70 | φ1.5 | 29.7 | 28 | 27.5 |

| 80 | φ1.5 | 29.7 | 32 | 31.4 |

| 90 | φ1.6 | 40 | 36 | 35.3 |

| φ18 | 20 | φ1.5 | 10 | 8 | 23.5 |

| 25 | φ1.6 | 12 | 10 | 29.4 |

| 30 | φ1.6 | 12 | 12 | 35.3 |

| 35 | φ1.7 | 16.2 | 14 | 41.2 |

| 40 | φ1.7 | 16.2 | 16 | 47.1 |

| 45 | φ1.8 | 19.8 | 18 | 53 |

| 50 | φ1.8 | 19.8 | 20 | 58.8 |

| 55 | φ1.8 | 19.8 | 22 | 64.7 |

| 60 | φ1.8 | 19.8 | 24 | 70.6 |

| 65 | φ2 | 32 | 26 | 76.5 |

| 70 | φ2 | 32 | 28 | 82.4 |

| 80 | φ2 | 32 | 32 | 94.1 |

| 90 | φ2.2 | 43 | 36 | 105.9 |

| 100 | φ2.2 | 43 | 40 | 117.7 |

*Other sizes are available. Please see the product pages.

Back to page top

Performance info.

■Spring constant of round wire coil spring, O.D. referenced type (N/mm)

| O.D. | Max deflection (Free length) Type |

| 75% | 60% | 45% | 40% | 40% | 35% | 30% | 25% |

| φ2 | - | - | - | 0.5 | - | - | - | - |

| φ3 | 0.1 | 0.3 | 0.5 | 1 | 1.5 | 2 | - | 3.9 |

| φ4 | 2.9 | 4.9 |

| φ5 | 2 | 2.9 | 5.9 | 9.8 |

| φ6 |

| φ8 |

| φ10 | 0.2 |

| φ12 |

| φ13 | 9.8 | 19.6 |

| φ14 |

| φ16 |

| φ18 | - | 0.5 | 1 | 2.9 | 3.9 | 4.9 | 14.7 | 29.4 |

| φ20 | - | - |

| φ22 | - | 29.4 |

| φ27 | - |

Back to page top

Technical calculations

■Coil spring load calculations

Load = Spring constant x Deflection

Back to page top

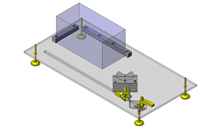

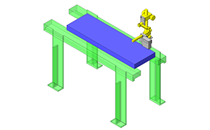

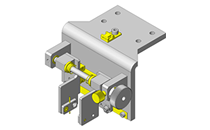

Height Adjust Pin

| Product name | Height Adjust Pins- Hex, B/F Standard |

| Part number | JPRA6-30.00 |

| Features | Can be used for height-adjusting. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Height accuracy is necessary for this application example.

Back to page top

Available sizes

■Height Adjust Pins- Hex, B/F Standard

| Material | Surface treatment | Hardness |

| 4137 Alloy Steel | − | Heat treated hardness 46~50HRC |

| Black oxide | Heat treated hardness 46~50HRC |

| Hard chrome plating | Heat treated hardness 46~50HRC |

| Plating thickness 3μm or more | Plating hardness 750HV~ |

| 304 Stainless Steel | − | − |

| 440C Stainless Steel | − | Heat treated hardness 50~55HRC |

■Sizes and Dimensions

Thread DIA.

(Coarse) | Head height | Head

Hex size | Under head

thread length |

| (Configure in 0.01mm increments) |

| M3 | 2.00〜10.00 | 6 | 5 |

| M4 | 7 | 6 |

| M5 | 8 | 8 |

| M6 | 5.00〜30.00 | 10 | 8 |

| M8 | 13 | 10 |

| M10 | 10.00〜50.00 | 17 | 12 |

| M12 | 19 | 15 |

Back to page top

Accuracy Info

■Accuracy of height adjust pins threaded type (Hex)

Head height tolerance: +0.01/0

Back to page top

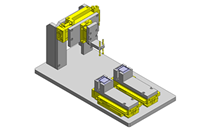

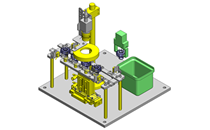

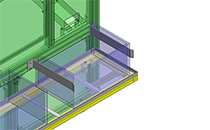

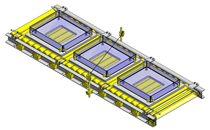

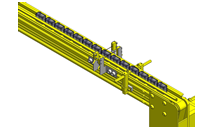

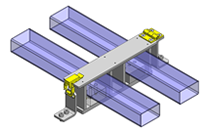

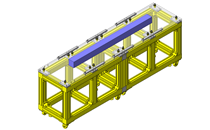

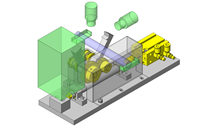

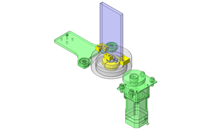

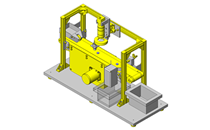

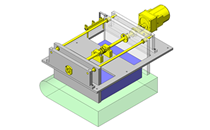

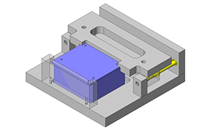

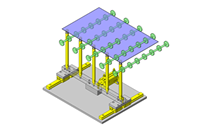

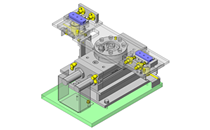

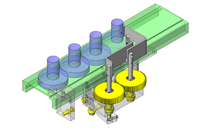

IDEA NOTE Up/down mechanism with springs and bushings + One touch holding.

The inspection instrument movements are guided by bushings and shafts, and raised by the springs. While inspecting, the toggle clamp pushes the inspection instrument down.