90 degree Brackets (Series: IMAO (I-Frame) 20 Series)

Ninety-degree brackets are essential components used to connect aluminum extrusions at precise right angles. These brackets come in various shapes and designs, catering to different assembly requirements and structural needs. Types include tabbed brackets for enhanced stability, extruded thick brackets for a seamless frame appearance, thin brackets for compact applications, and triangle brackets for sturdy connections. Additional features may include slotted holes for flexible mounting, dust-proof covers, and easy-to-install nut-fastened options. These brackets are compatible with different series of aluminum frames, ensuring versatility in both industrial and architectural applications.

More

Less

Bracket Type Details

Brand(1 brands)

Days to Ship

- All

- 6 Day(s) or Less

2Items

Sort by

- Keyword Selected :

- Series: IMAO (I-Frame) 20 Series

- From :฿ 117.00Special Price35 Day(s)

Categories Recommended

Application Example Related to This Category

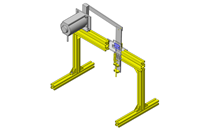

Try to Find Other Examples Clearing Mechanism Using Air Blow

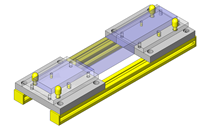

Clearing Mechanism Using Air Blow Film Press Bonding Fixture

Film Press Bonding Fixture Surface Locating Mechanism using Two Flat Plates

Surface Locating Mechanism using Two Flat Plates Test Fixture for Product Aging

Test Fixture for Product Aging

FAQ 90 degree Brackets

- Question: What are 90-degree brackets used for?

- Answer: Ninety-degree brackets are used to connect aluminum extrusions at right angles. They provide structural support and ensure precise alignment in various assemblies, such as frames, enclosures, and workbenches.

- Question: What types of 90-degree brackets are available?

- Answer: There are several types of 90-degree brackets, including tabbed brackets for stability, extruded thick brackets for a uniform look, thin brackets for compact spaces, and triangle brackets for added sturdiness. Each type serves different assembly requirements.

- Question: How do tabbed brackets enhance connection stability?

- Answer: Tabbed brackets feature protrusions on the connecting surfaces that prevent rotation during assembly. This design ensures a secure and stable connection, making them ideal for applications requiring high precision and reliability.

- Question: Can 90-degree brackets be used with different series of aluminum frames?

- Answer: Yes, 90-degree brackets are compatible with various series of aluminum frames, including 5 Series, 6 Series, 8 Series, and others. This compatibility allows for flexible design and assembly options across different projects.

- Question: What additional features can be found in 90-degree brackets?

- Answer: Some 90-degree brackets come with additional features such as slotted holes for adjustable mounting, dust-proof covers, nut-fastening for simplified installation, and gussets for easy fastening with hex wrenches. These features enhance the functionality and ease of use of the brackets.

- Question: How do I choose the right 90-degree bracket for my application?

- Answer: Selecting the right 90-degree bracket depends on the specific requirements of your project. Consider factors such as the type of connection, load-bearing needs, available space, and compatibility with the aluminum frame series you are using. Reviewing the technical specifications and features of each bracket type will help in making an informed decision.

- Question: Are there brackets designed for aesthetic purposes?

- Answer: Yes, extruded thick brackets are designed to blend seamlessly with the frame, offering a uniform and aesthetically pleasing appearance. These brackets are ideal for applications where the visual aspect is important, such as in display frames or architectural structures.

- Question: What materials are 90-degree brackets typically made of?

- Answer: Most 90-degree brackets are made from high-strength aluminum, ensuring durability and lightweight properties. Some brackets also feature additional treatments, such as anodizing, to enhance corrosion resistance and improve their appearance.

- Question: Can 90-degree brackets be used in heavy-duty applications?

- Answer: Yes, specific types of 90-degree brackets, such as extruded thick and triangle brackets, are designed for heavy-duty applications. They provide robust support and stability, making them suitable for use in industrial machinery, structural frameworks, and other demanding environments.

- Question: How do single-gusseted brackets simplify installation?

- Answer: Single-gusseted brackets allow for easy fastening using a hex wrench, eliminating the need for complex tools or adjustments. This feature makes the installation process quicker and more straightforward, especially in tight or hard-to-reach spaces.

Chat with MISUMI

Chat service is available for any inquiry to MISUMI

Service hours

9:00 - 18:00 (Mon-Sat)

For out of service hours, you can leave a message to us.

We will reply to your inquiries on the next business day.

(except Sundays and public holidays).

Noted for use

Chat service is for Corporate customers and limited for Thai language.

Request for Quotation and Place Order is not available on Chat.

This Website uses cookies. Please accept our cookie policy for your best experience.

You can learn more on how to adjust your cookie setting in our Privacy Policy here