(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000077 Pressure Labeling Fixture

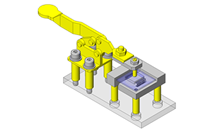

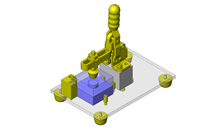

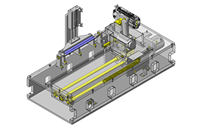

No.000077 Pressure Labeling Fixture

49

49

Long stroke toggle mechanism

Relevant category

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Labels are pressure bonded on stainless steel cases with manufactured toggle mechanism .

Points for use

- Labeling is manual, lever operated toggle mechanism.

Target workpiece

- Stainless steel case

External dims.: W50 x D30 x H19 mm - Label

External dims.: W50 x W30 x t (mm)

Design Specifications

Operating Conditions or Design Requirements

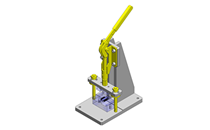

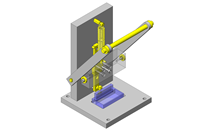

- External dimensions: W135 x D150 x H350 mm (Top edge of side plate)

- Moving section stroke: 50mm

Required Performance

- Operating load: 27.15N

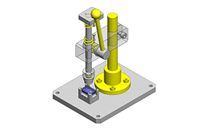

Combination of compression and tension springs.

Selection Criteria for Main Components

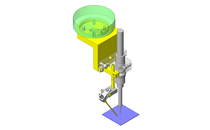

- Tension springs

- Extra light tension spring with long stroke.

Design Evaluation

Verification of main components

- Select a spring type with appropriate operation load.

- Operational force

- Operational force = Compression spring load + Tension spring load = 13.72 + 13.43 = 27.15N

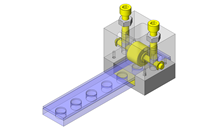

- Compression spring load

- Calculation formula: Reaction force F- kx

- Assumed applied pressure load (2pcs. used): 13.72N

- Assumed deflection when lever operated: x = 7mm (when set 1mm, stroked 6mm)

- k = F / x / (number of springs) = 13.72 / 7 / 2 = 0.98

- Spring constant: k = 0.98 N/mm selected

- Tension spring load

- Calculation formula: Reaction force F= kx + initial tension

- Assumed operation load (2pcs. used): F = 13.43N

- Initial tension: 1.08N

- Assumed deflection in operation: x = 74.4mm (when set 24.4mm, stroke 50mm)

- Spring constant: k = (13.43 - 1.08) / 74.4 / 2 = 0.083N/mm selected

Other Design Consideration

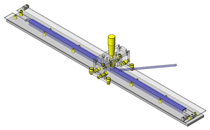

- Connection of the lever operation section and moving section is established by a linking mechanism.

- Shafts act as guides to allow for smooth operation.

- Compression spring load is adjusted by adjusting base guide position.

- Lubrication-free bushings are used for smooth sliding operation .

Explore Similar Application Examples

Page

-

/

-