(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

Linear Shafts(Page2)

Configure

Specification/Dimensions

-

Environmentally friendly

-

Characteristics/Applications

-

End Shape (Left)

-

End Shape (Right)

-

Clamping Tool Type

- Not Provided

-

Shaft End Perpendicularity

-

Material

-

Heat Treatment

- Not Provided

- Induction Hardened

-

Surface Treatment

-

Shaft Dia. D(Ø)

-

Material Details

-

Shaft Fits

-

Cleaning Method

|

Basic Shape

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

- 108 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Linear Shafts-One End Male Thread with Thread Dia. Equal to Shaft Dia.-

MISUMI

[Features] Shafts (linear shafts, hardened shafts, guide shafts, slide shafts) with male threads on one end and the same diameter. L size standard expanded! You can now purchase from an even more complete lineup.Days to Ship: 3 Day(s)

3 Day(s)

-

You can add up to 6 items per a category to the compare list.

Precision Linear Shafts - One End Stepped and Male Thread One End Female Thread Type

MISUMI

[Features] Shafts (linear shafts, hardened shafts, guide shafts, slide shafts) with a stepped male thread on one end and a female thread on one end. L size standard expanded! You can now purchase from an even more complete lineup.Days to Ship: 3 Day(s)

3 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Shaft - Both Ends Threaded with Undercut](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639179/110310639179_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Shaft - Both Ends Threaded with Undercut

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Shaft - One End Threaded](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639809/110310639809_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Shaft - One End Threaded

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Shaft - One End Threaded with Wrench Flats](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639899/110310639899_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Shaft - One End Threaded with Wrench Flats

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Shaft with Retaining Ring Groove](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310638909/110310638909_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Shaft with Retaining Ring Groove

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Shaft - One End Threaded and One End Tapped](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639629/110310639629_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Shaft - One End Threaded and One End Tapped

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

Linear Shaft, Straight Type, NS Series

OZAK

[Features]

· Rigid chrome plating SUJ-2 stainless steel, straight overall length standard shaft

· Can be cut to any desired overall length and delivered.

[Note]

"C" is included in the part numbers in the manufacturer's catalog for ordering a custom specific size.

Customers can order both standard size and custom specific dimension products on MISUMI website, even though the part numbers do not contain "C."Days to Ship: 23 Day(s)

23 Day(s)

-

You can add up to 6 items per a category to the compare list.

Precision Linear Shafts - Both Ends Male Thread with Undercut

MISUMI

[Features] Shafts (linear shafts, hardened shafts, guide shafts, slide shafts) with male screw relief grooves on both ends. L size standard expanded! You can now purchase from an even more complete lineup.Days to Ship: 3 Day(s)

3 Day(s)

-

You can add up to 6 items per a category to the compare list.

MISUMI

[Features] High squareness accuracy (0.03) at the shaft end and guaranteed coaxiality of 0.02 for linear motion shafts (linear shafts, hardened shafts, guide shafts, slide shafts) with male thread relief grooves on both ends/with male thread relief grooves on both ends It is a type with a spanner groove.Days to Ship: 7 Day(s)

7 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Shaft - One End Tapped with Wrench Flats](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639539/110310639539_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Shaft - One End Tapped with Wrench Flats

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Shaft - One End Threaded with Undercut and Wrench Flats](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639989/110310639989_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Shaft - One End Threaded with Undercut and Wrench Flats

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 5 Day(s)

5 Day(s)

-

Economy seriesYou can add up to 6 items per a category to the compare list.

Linear shaft One End Stepped and Tapped with Wrench Flats

This is an economy item, The price is cheaper than the MISUMI standard product.Days to Ship: 8 Day(s)

8 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Shaft - One End Keyway](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310638999/110310638999_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Shaft - One End Keyway

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Shaft - Both Ends Threaded with Wrench Flats](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639719/110310639719_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Shaft - Both Ends Threaded with Wrench Flats

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

Days to Ship: 5 Day(s)

5 Day(s)

-

Economy seriesYou can add up to 6 items per a category to the compare list.

Days to Ship: 9 Day(s)

9 Day(s)

-

Economy seriesYou can add up to 6 items per a category to the compare list.

Days to Ship: 9 Day(s)

9 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Environmentally friendly |

| Basic Shape |

| Characteristics/Applications |

| End Shape (Left) |

| End Shape (Right) |

| Clamping Tool Type |

| Shaft End Perpendicularity |

| Material |

| Heat Treatment |

| Surface Treatment |

| Shaft Dia. D(Ø) |

| Material Details |

| Shaft Fits |

| Cleaning Method |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | OZAK | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | |||

| Product Series | Linear Shafts-One End Male Thread with Thread Dia. Equal to Shaft Dia.- | Precision Linear Shafts - One End Stepped and Male Thread One End Female Thread Type | Precision Linear Shafts - Both Ends Male Thread with Undercut | [Clean & Pack] Shaft - One End Threaded with Undercut and Wrench Flats | ||||||||||||||

| CAD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| From | ||||||||||||||||||

| Days to Ship | 3 Day(s) | 3 Day(s) | 5 Day(s) | 5 Day(s) | 5 Day(s) | 5 Day(s) | 5 Day(s) | 23 Day(s) | 3 Day(s) | 7 Day(s) | 5 Day(s) | 5 Day(s) | 8 Day(s) | 5 Day(s) | 5 Day(s) | 5 Day(s) | 9 Day(s) | 9 Day(s) |

| Environmentally friendly | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Basic Shape | Solid | One End Stepped | Solid | Solid | Solid | Solid | Solid | Solid | Solid | Solid | Solid | Solid | One End Stepped | Solid | Solid | Solid | Hollow | Hollow |

| Characteristics/Applications | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| End Shape (Left) | Threaded | Threaded | Threaded | Threaded | Threaded | With Retaining Ring Grooves | Threaded | - | Threaded | Threaded | Tapped | Threaded | Tapped | Keyway | Threaded | No Machining | No Machining | Tapped |

| End Shape (Right) | No Machining | Tapped | Threaded | No Machining | No Machining | With Retaining Ring Grooves | Tapped | - | Threaded | Threaded | No Machining | No Machining | No Machining | No Machining | Threaded | Tapped Hole | No Machining | Tapped |

| Clamping Tool Type | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Shaft End Perpendicularity | Perpendicularity (0.2) | Perpendicularity (0.2) | Perpendicularity (0.2) | Perpendicularity (0.2) | Perpendicularity (0.2) | Perpendicularity (0.2) | Perpendicularity (0.2) | - | Perpendicularity (0.2) | Perpendicularity (0.03) | Perpendicularity (0.2) | Perpendicularity (0.2) | Perpendicularity (0.2) | Perpendicularity (0.2) | Perpendicularity (0.2) | Perpendicularity (0.2) | Perpendicularity (0.2) | Perpendicularity (0.2) |

| Material | Stainless Steel ~ Steel | Stainless Steel ~ Steel | Steel | Steel | Steel | Steel | Steel | Steel | Stainless Steel ~ Steel | Stainless Steel ~ Steel | Steel | Steel | Stainless Steel ~ Steel | Steel | Steel | Stainless Steel ~ Steel | Steel | Steel |

| Heat Treatment | Not Provided / Induction Hardened | Not Provided / Induction Hardened | Not Provided | Not Provided | Not Provided | Not Provided | Not Provided | Induction Hardened | Not Provided / Induction Hardened | Induction Hardened | Not Provided | Not Provided | Induction Hardened | Not Provided | Not Provided | Induction Hardened | Induction Hardened | Induction Hardened |

| Surface Treatment | Not Provided / Hard Chrome Plating / Low Temperature Black Chrome Plating | Not Provided / Hard Chrome Plating / Low Temperature Black Chrome Plating | Hard Chrome Plating | Hard Chrome Plating | Hard Chrome Plating | Hard Chrome Plating | Hard Chrome Plating | Hard Chrome Plating | Not Provided / Hard Chrome Plating / Low Temperature Black Chrome Plating | Not Provided / Hard Chrome Plating / Low Temperature Black Chrome Plating | Hard Chrome Plating | Hard Chrome Plating | Not Provided / Hard Chrome Plating | Hard Chrome Plating | Hard Chrome Plating | Not Provided / Hard Chrome Plating | Hard Chrome Plating | Hard Chrome Plating |

| Shaft Dia. D(Ø) | 3 ~ 30 | 8 ~ 50 | 8 ~ 50 | 6 ~ 50 | 6 ~ 50 | 6 ~ 30 | 6 ~ 50 | 3 ~ 40 | 8 ~ 50 | 8 ~ 30 | 6 ~ 50 | 8 ~ 50 | 8 ~ 30 | 6 ~ 50 | 6 ~ 50 | 15 ~ 30 | 6 ~ 30 | 6 ~ 30 |

| Material Details | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Shaft Fits | h5 ~ f8 | h5 ~ f8 | f8 | f8 | f8 | f8 | f8 | g6 | h5 ~ f8 | g6 | f8 | f8 | g7 | f8 | f8 | g6 | g7 | g7 |

| Cleaning Method | - | - | Degreasing / Precision Cleaning | Degreasing / Precision Cleaning | Degreasing / Precision Cleaning | Degreasing / Precision Cleaning | Degreasing / Precision Cleaning | - | - | - | Degreasing / Precision Cleaning | Degreasing / Precision Cleaning | - | Degreasing / Precision Cleaning | Degreasing / Precision Cleaning | - | - | - |

Loading...

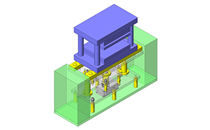

Application example related to this category

Related Categories to Linear Shafts

-

- Linear Shafts

- Shaft Supports

- Shaft Collars

- Linear Bushings

- Ball Guides

- Spline Shaft

- Oil Free Bushings, Washers

- Linear Motor Actuators

- Oil Free Plates, Guide Rails

- Linear Guides

- Cable Carriers

- Ball Screw

- Support Units

- Lead Screws, Slide Screws

- Cross Roller

- Slide Packs, V Guides, Linear Rails

- Actuators/Single Axis Robot

- Other Linear Motion Related Components

- Bellows

-

![[Clean & Pack] Shaft - Both Ends Threaded with Undercut](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639179/110310639179_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Shaft - One End Threaded](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639809/110310639809_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Shaft - One End Threaded with Wrench Flats](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639899/110310639899_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Shaft with Retaining Ring Groove](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310638909/110310638909_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Shaft - One End Threaded and One End Tapped](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639629/110310639629_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Shaft - One End Tapped with Wrench Flats](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639539/110310639539_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Shaft - One End Threaded with Undercut and Wrench Flats](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639989/110310639989_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Shaft - One End Keyway](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310638999/110310638999_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Shaft - Both Ends Threaded with Wrench Flats](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/t_misumi_wm/v1/p/jp/product/series/110310639719/110310639719_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Shaft - Both Ends Threaded with Undercut](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/t_misumi_wm/v1/p/jp/product/series/110310639179/110310639179_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack] Shaft - One End Threaded](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/t_misumi_wm/v1/p/jp/product/series/110310639809/110310639809_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack] Shaft - One End Threaded with Wrench Flats](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/t_misumi_wm/v1/p/jp/product/series/110310639899/110310639899_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack] Shaft with Retaining Ring Groove](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/t_misumi_wm/v1/p/jp/product/series/110310638909/110310638909_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack] Shaft - One End Threaded and One End Tapped](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/t_misumi_wm/v1/p/jp/product/series/110310639629/110310639629_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack] Shaft - One End Tapped with Wrench Flats](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/t_misumi_wm/v1/p/jp/product/series/110310639539/110310639539_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack] Shaft - One End Threaded with Undercut and Wrench Flats](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/t_misumi_wm/v1/p/jp/product/series/110310639989/110310639989_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack] Shaft - One End Keyway](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/t_misumi_wm/v1/p/jp/product/series/110310638999/110310638999_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack] Shaft - Both Ends Threaded with Wrench Flats](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/t_misumi_wm/v1/p/jp/product/series/110310639719/110310639719_001_20230911105917.jpg?$product_view_c$)

How can we improve?

How can we improve?