(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 28/7/2024 to 6:00 29/7/2024. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

Floating Joints

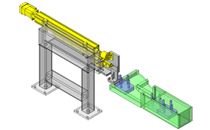

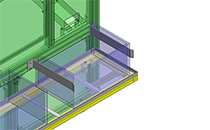

Floating Joints products from the Automation Components category can be selected based on many product specifications such as Type. The recommended brands for Floating Joints are MISUMI, CHELIC, CKD. The products of Floating Joints are offered in a total of 0 items and the product details can easily be compared. Search and select detailed specifications of parts for your machine with free CAD downloads. Wide range variety of product, on time delivery free of charge and no minimum order.

|

Type

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

Product not found.

Loading...

Related Categories to Floating Joints

FAQ Floating Joints

- Question: What are Floating Joints and their primary function?

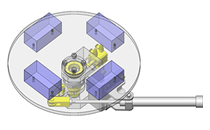

- Answer: Floating Joints are mechanical components designed to compensate for misalignment between a cylinder rod and the driven workpiece. They absorb both lateral (side-to-side) and angular (rotational) misalignment, ensuring smooth linear motion and preventing damage to connected parts.

- Question: How do Floating Joints improve installation accuracy?

- Answer: Floating Joints significantly reduce the need for precise alignment during installation. Their ability to accommodate misalignment simplifies the process, reducing the need for high-precision machining and alignment of connected components.

- Question: What types of Floating Joints are available?

- Answer: Floating Joints are offered in various configurations to suit different applications:

Quick Connection Type: Facilitates easy and fast installation with a holder.

Tapped Type: Connects directly to components with tapped threads.

Flange Mounting: Mounts via either round or square flanges.

Screw Mount Type: Features various sizes with threaded connections. - Question: What materials are used in Floating Joints?

- Answer: Floating Joints are commonly constructed from brass, stainless steel, or carbon steel. Surfaces are often treated with hard chrome plating or electrophoretic paint to enhance durability and resistance to abrasion and corrosion.

- Question: How do I choose the right Floating Joint for my application?

- Answer: Consider the following factors when selecting a Floating Joint:

Connecting Thread Nominal (M): The size of the thread on both the cylinder side and the workpiece side.

Connection Type: Threaded, tapped, or flange mount.

Applicable Cylinder: Compatibility with air or hydraulic cylinders.

Allowable Misalignment and Angular Deviation: Ensure the joint can handle the expected misalignment in your specific setup. - Question: What are the operational limits of Floating Joints?

- Answer: Temperature Range: Typically -20°C to 70°C (-4°F to 158°F), but can vary depending on materials and surface treatment.

Misalignment Capacity: Varies by type and size. Check specifications for allowable lateral offsets and angular deviation. - Question: What precautions should be taken when using Floating Joints?

- Answer: Avoid Rotary Motion: Floating Joints are designed for linear motion only.

Cushioning Mechanism: Use cylinders with built-in cushioning to prevent impact damage to the joint.

External Stop Structures: Consider external stop cushioning to absorb excessive impact loads and protect equipment. - Question: Can Floating Joints be used in compact or confined spaces?

- Answer: Yes, compact and ultra-short Floating Joint designs are available specifically for use in tight spaces.

- Question: What are the benefits of using Floating Joints in automation systems?

- Answer: Reduced Installation Time: Simplified alignment saves time.

Increased Longevity: Reduced stress on components extends their lifespan.

Versatility: Suitable for a wide array of factory automation applications.

How can we improve?

How can we improve?