Flat Belts For Sliding

Caution

- Canvas with sliding property in longitudinal direction are adopted, which can make the conveyed objects stay and arrange above the belt. It is suitable for longitudinal sliding (conveying direction), and for transverse sliding (belt width direction), please select existing products.

- Price updated from 05102025

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part08 CLICK here

Product Description

Flat Belts For Sliding

This conveyor belt is ideal for use in both sliding transfer and mini belt conveyor systems, with a wide range of sizes available to choose from.

[Feature]

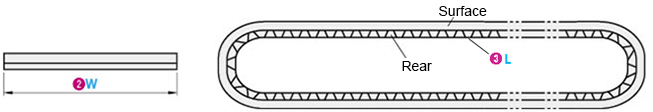

● Belt Width Minimum / Maximum (mm.) : 10 mm. and 500 mm. (can be increased by increments 1 mm.)

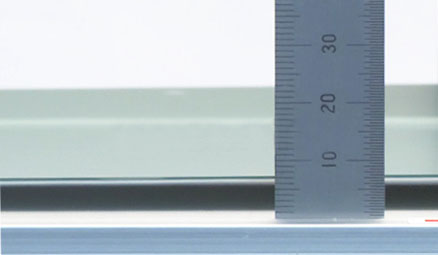

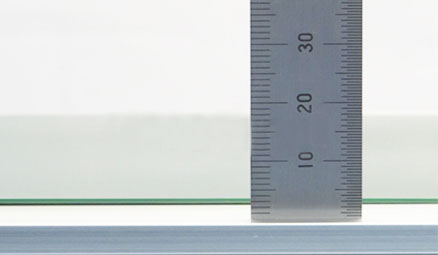

● Thickness Minimum/ Maximum (mm.): 0.5 and 1.2

● Belt Length (m.) : The size is configurable between 0.7 to 20 m., and the minimum length can be increased by increments 0.01 m.

● Surface Cover Polyester Impregnated Woven Cloth

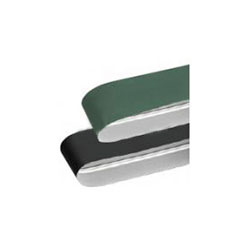

● Color: Green and White

[Application]

It is used in conjunction with pulleys to transfer materials in a conveyor system.

Economy Flat Belts For Sliding

- Engineered for smooth longitudinal transfer with advanced technology.

- Choose from a wide range of belt widths and lengths to match your needs.

- Available in versatile colors to suit your system's requirements.

- Polyester impregnated woven cloth provides durability and sliding performance.

- Perfect for mini conveyor systems with configurable options for a precise fit.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product Overview

Dimensional Drawing

Specifications Overview

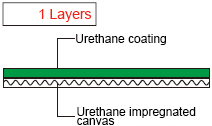

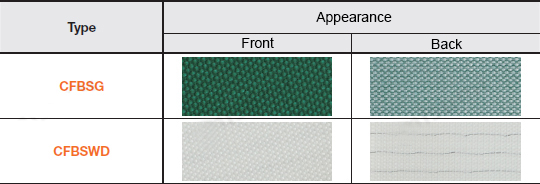

| Type |  Material Material | Color | Surface Shape | Number of Layers | Thickness mm | Minimum pulley diameter Φmm | Allowable tension N/mm | Unit weight kg/㎡ | Coefficient of friction (reference value for ground steel) | Knife edge | Continuous Operating Temperature °C | ||

| Surface | Rear | Surface | Rear | ||||||||||

| CFBSG | Urethane impregnated | Polyester canvas | Green | Flat Surface | 1 | 0.5 | 10 | 4 | 0.3 | 0.2 | 0.1 | R4 | -20~80 |

| CFBSWD | White | 2 | 1.2 | 20 | 6 | 1.2 | 0.2 | 0.1 | R5 | ||||

The permanent stretch rate of the Conveyor Belt is 1% relative to the total length. (Reference value)

The permanent stretch rate of the Conveyor Belt is 1% relative to the total length. (Reference value) At the time of shipment, fitting processing has been performed on the ribbon belt.

At the time of shipment, fitting processing has been performed on the ribbon belt. Set the inner diameter as the circumference length.

Set the inner diameter as the circumference length. Please select the pulley model after confirming the width tolerance between the pulley and the idler.

Please select the pulley model after confirming the width tolerance between the pulley and the idler.| Width (mm) | Tolerance |

| ~100 | 0 ~ -2 |

| 101~400 | 0 ~ -2 |

| 401~500 | 0 ~ -3 |

| Thickness (mm) | Tolerance | Fitting Part Tolerance |

| ~1.0 | ±0.1 | ±0.3 |

| 1.1~1.5 | ±0.2 |

| Length (mm) | Tolerance |

| ~2000 | ±10 |

| 2001~7000 | ±20 |

| 7001~10000 | ±0.3% |

| 10001~ | ±0.3% |

Specification Table

to

to  .

. |  Part Number Type Part Number Type | - |  Conveyor Belt Width W (mm) Conveyor Belt Width W (mm) | - |  Circumference Length L (m) Circumference Length L (m) | ||||

| CFBSG | - | 350 | - | 4.23 | |||||

■Specification Table

| Part Number |  Circumference Length Ⅼ(m) Circumference Length Ⅼ(m) | |

Type Type |  Conveyor Belt Width W (mm) Conveyor Belt Width W (mm)Can be specified down to 1mm increments | Can be specified down to 0.01m increments |

| CFBSG | 10~500 | 0.70~20.00 |

| CFBSWD | ||

At the time of shipment, fitting processing has been performed on the ribbon belt.

At the time of shipment, fitting processing has been performed on the ribbon belt.Product Features

For general use: suitable for general conveying purposes of food packaging, cardboard boxes, metal, and plastic, etc.

For electronic parts: anti-static specifications, suitable for the transmission of anti-static electronic parts. The surface resistivity value is 10⁶~10⁸Ω.

For sliding: canvas with sliding performance in longitudinal direction is used to make the conveying objects stay and be arranged above the belt.

For conveying bulk materials: The surface is of textured shape, which can be used in horizontal transportation of bulk objects.

|  |  |  |  |  |  |  | |||||||

For general use | For general use | For general use | For electronic parts | For sliding | For sliding | For conveying bulk materials | For conveying bulk materials |

Feature 2: Can prevent both sides of the belt from being raised

For 1 layer of flat belt, the back is made of weaving with stronger rigidity to effectively prevent the belt from being raised on both sides.* Problems of products circulating on the market.

Feature 3: more layers and types are available

The results of MISUMI Conveyor Belt installation test are for reference only.

The results of MISUMI Conveyor Belt installation test are for reference only.Precautions

| Part Number | Surface Material Performance Table | ||||

| Type | Chemical resistance of covering layer | Tolerance to animal and vegetable oils | Flame Retardance | Water and heat resistance | Static resistance |

| CFBSG | 〇 | 〇 |  | 〇 |  |

| CFBSWD | 〇 | 〇 |  | 〇 |  |

Applicable 〇 May be corroded

Applicable 〇 May be corroded  Not applicable

Not applicable

Not suitable for unpackaged food transportation.

Not suitable for unpackaged food transportation.■ Belt appearance list

Usage Method

The suitable tension force of the flat belt depends on the structure of the conveyor, material, the weight of the goods, etc., so it can not be determined as a few percent.

Please do not over-tension as it is permanently tensioned. Please refer to the following method for adjusting method.

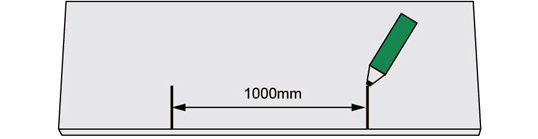

① Select a length of 1000mm and draw a mark on an inconspicuous part of the Conveyor Belt.

② Slowly tension the flat belt until the marking line reaches 1002mm.

③ Drive the Conveyor Belt in this state and confirm that the flat belt is not slipping. (If the flat belt deflects, then adjust it)

Carry out the transmission test after confirming no problems. If the transmission is smooth, you can continue to use the belt.

If the flat belt slips after the item is put on, perform Step ④.

④ When the Conveyor Belt slips, please tighten the flat belt slightly. Every time you need to confirm the slip until the flat belt does not slip.

Adjust the deviation and carry out the transmission test. Confirm smooth transmission before use.

⑤ It is recommended to check the tension state regularly.

■ Simple selection steps for Conveyor Belt

① Determine the necessary conditions for selection. (Maximum total weight of workpiece, pulley diameter, transmission power, etc.)

② Calculate the stress borne by the belt.

③ Choose the belt whose allowable stress is greater than the stress calculated in ②.

④ Confirm the oil resistance and chemical resistance of the belt, and confirm the sliding properties based on the coefficient of friction.

⑤ Determine the Conveyor Belt.

Example of Use

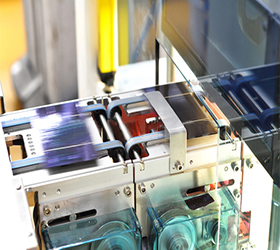

Equipment name: cutting mechanism for workpieces in vertical stacking

Intended use: cut the vertically stacked covers one by one and send them out to the structure that is glued to the cylindrical workpiece

Structure and design points: to cut the vertically stacked covers one by one, use a flat belt for sliding, and match the shape of the sliding tray to the cover, and send them out one by one.

Application Industries

| Smart phone | Food | Electronic & Electrical Appliances | ||

|  |  | ||

| Solar cell | Semiconductor | LCD | ||

|  |  |

Related Products

| Urethane round belt, welded joint product, free end product, hollow rope type | Conveyor Belt, Flat belt, with anti-running rib | Conveyor Belt, flat belt with anti-running rib and single row middle drive, φ30 | ||

|  |  | ||

| Typical model: MBT5-150 | Typical model: HBLTDS350-4.5 | Typical model: CVGP-100-1000-25-TA220-IM-25-H-A | ||

| Reasons for recommendation: rich specifications, excellent quality | Reasons for recommendation: anti-running rib design | Reasons for recommendation: anti-running rib models effectively prevent deviation |