(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

- > No.000180 Mechanism to Check Part Condition

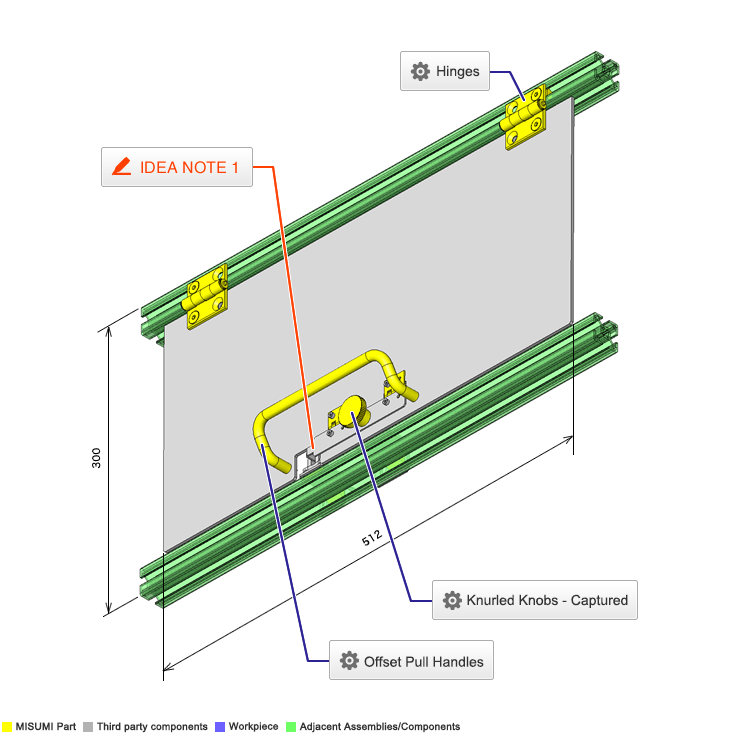

No.000180 Mechanism to Check Part Condition

22

22

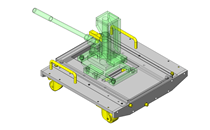

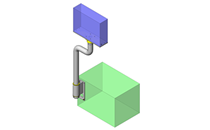

Sensor position adjustments using a spring hinge.

Relevant category

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Purpose

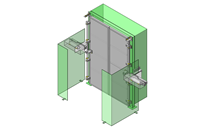

- Prevents failure when closing or affixing the maintenance door.

- Operation

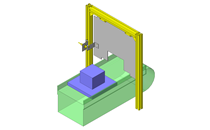

- After closing the door, fix the bracket connected to the door with the spring hinge using the knurled knob. At this point, the bracket shields the sensor from light. By removing the knurled knob, the bracket and knob are flipped up, tripping the check sensor.

Points for use

- Manually operated.

Target workpiece

- Doors that require interlock.

Design Specifications

Selection Criteria for Main Components

- Spring hinges that can be flipped up against the weight of the knob.

Design Evaluation

Verification of main components

- The spring hinges are verified based on the load moment, to see whether the dog moves away from the sensor.

-

- Conditional Value:

Total mass of dog and knob: m = 0.10kg

Horizontal distance between hinge shaft and center of gravity of dog and knob: a 20.0mm

Load of hinge spring: k = 0.40kgf

Hinge spring load definition angle: θ = 270°

Hinge spring load position: b = 16mm

Number of hinge springs: n = 2pieces

Hinge spring load in free condition: k0 = 0.10kgf

Hinge spring angle in free condition: θ0=90°

Target hinge angle: θ1 = 225°

Gravitational acceleration: g = 9.8m/s2

Hinge spring load at target angle: k1 = {(k - k0)/(θ - θ0)} x θ1 = {(0.4 - 0.1)/(270 - 90)} x 225 = 0.375kgf

Total hinge spring load at target angle: k1' = k1 x n = 0.375 x 2 = 0.75kgf

Moment by dog and knob: M1=m x g x a, hence, M1 = 0.1 x 9.8 x 20 = 2.0kgf・mm

Moment by hinge: M2 = k1' x b, hence, M2 = 0.75 x 16 = 12.0kgf・mm

From M1 < M2, the angle of the hinge at an unfixed state satisfies the target angle θ1 at which the dog moves away from the sensor.

- Conditional Value:

Other Design Consideration

- The mechanism is designed so that when flipped up, the spring hinge flips the total weight of the dog away from the sensor.

- The photomicrosensor should be set to turn on when shielded from light, and the interlock should be applied when the sensor turns off due to the door being open or failure of the sensor.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category