(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- inCAD Library Home

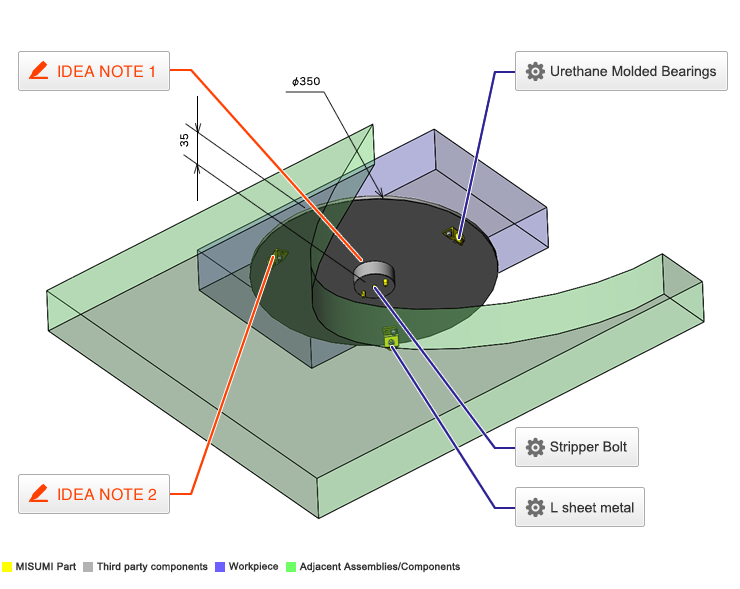

- > No.000183 Removable Turntable

No.000183 Removable Turntable

11

11

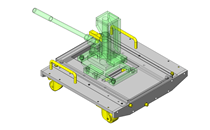

Bottom view of removable turntable.

Relevant category

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Purpose

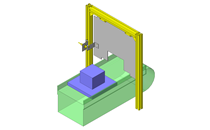

- Used for product inspection/repair.

- Operation

- Product inspection and repair are conducted on a workbench. If the turntable is not needed, it is removable by loosening center turntable bolt. When re-installing, use the two center locating pins to position the table and tightening the center bolt.

Points for use

- The turntable is rotated manually.

Target workpiece

- Shape: Block

- Size: W 430 x D 250 x H 70 mm

- Weight: 6 kg

Design Specifications

Operating Conditions or Design Requirements

- Turntable O.D.: φ350mm

- External size (workbench): W 700 x D 600 x H 170 mm

Selection Criteria for Main Components

- Select size for urethane molded bearings to support motions and to prevent deflection of the turntable.

Design Evaluation

Verification of main components

- Verify bearing durability or life span based on load rating.

- Calculate life span of the bearing

- Life span for bearings (106 rotations): L = (Cr/Pr)³ , where

Cr=7250N - Basic Dynamic load rating for B6906ZZ (from catalog)

Pr- Radial Dynamic Equivalent load (need to calculate based on application loads) - Other conditionals values:

Workpiece weight: M = 6 kg

Gravitational acceleration: g = 9.8 m/s²

Gravity by the workpiece: W = M x g = 6 x 9.8 = 59 N

Manual force used to move turntable: Assume to be Q = 200 N - Radial Dynamic Equivalent load

Pr =X×Fr + Y×Fa, where Fr-radial load, Fa-thrust load and X=1 and Y=2.3 are radial and thrust factor (values from catalog) - Assume that force acting on the bearing, Po = M + Q, acts only in the z-axis direction (thrust load), and let radial load Fr=0N, then we obtain the following:

Thrust load: Fa=Po=M+Q=259N、then

Pr=1×Fr+2.3×(M+Q)=1×0+2.3×259=596N - Bearing rated life L = (Cr/Pr)³ = (7250/596)³ = 1800 (10? rotations), has sufficient margin for our application.

- Life span for bearings (106 rotations): L = (Cr/Pr)³ , where

Other Design Consideration

- Securing repeatability of the turntable position and fixing the turntable with one bolt.

- In this example two round locating pins are used for turntable positioning, combination of round and diamond pin can also be effectively used.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category