(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

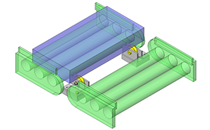

Hinge Pins(Mounting Method:Nut (Threaded))

Configure

Specification/Dimensions

-

Shaft Dia. D(mm)

-

Environmentally friendly

-

Mounting Method

-

Straight

Straight -

Retaining Ring

Retaining Ring -

Cotter Pin

Cotter Pin -

Nut (Threaded)

Nut (Threaded) -

Tapped

Tapped -

Set Screw (Set Screw Flat, D-Cut)

Set Screw (Set Screw Flat, D-Cut) -

Keyway

Keyway -

Set Screw (V Groove)

Set Screw (V Groove)

-

-

Characteristics/Applications

-

Basic Shape

-

Shouldered

Shouldered -

Straight

Straight -

Keyway

Keyway

-

-

Material

- Steel

- Stainless Steel

-

Hardness

- Not Spec-designed

- Hardness Spec-designed

-

Surface Treatment

- Not Provided

- Black Oxide

- Electroless Nickel Plating

- Hard Chrome Plating

-

Material Details

- SUS304

- SUS304 Equivalent

- SUS304-CP

-

Cleaning Method

- Degreasing

- Precision Cleaning

- Electrolytic Polishing + Precision Cleaning

Brand |

|

|---|---|

Filter By |

|

| CAD |

|

| Days to Ship |

|

- 9 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025

Until 31/03/2025

Until 31/03/2025Pivot Pins - Lock Nut with Shoulder

MISUMI

[Specification expansion]

Added hard chrome plating with excellent wear resistance.

[Features]

Hinge pin that can be tightened with a spanner.Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Pivot Pins - Lock Nut with Hex Socket Head

MISUMI

[Features]

Hinge pin that can be tightened with a hex wrench.Days to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

Days to Ship: 7 Day(s)

7 Day(s)

-

You can add up to 6 items per a category to the compare list.

Pivot Pins - Lock Nut with Extra Low Hex Socket Head

MISUMI

[Standard expansion]

We have added a U-nut type that can be expected to have a high loosening prevention effect.

Added hard chrome plating with excellent wear resistance.

[Features]

Compact design is possible due to the extremely low head.

A hinge pin that can be tightened with a hex wrench.Days to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

Days to Ship: 10 Day(s)

10 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Pivot Pin - Hex Socket, Shouldered, Lock Nut](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310641429/110310641429_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Pivot Pin - Hex Socket, Shouldered, Lock Nut

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 9 Day(s)

9 Day(s)

-

You can add up to 6 items per a category to the compare list.

Pivot Pins - Both Ends Threaded

MISUMI

[Specification expansion]

Added electroless nickel plating.

Added hard chrome plating with excellent wear resistance.

[Features]

A hinge pin that can be firmly fixed with nuts on both ends.Days to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Pivot Pin - Shouldered, Lock Nut](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310641339/110310641339_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Pivot Pin - Shouldered, Lock Nut

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 7 Day(s)

7 Day(s)

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Pivot Pin - End Shape Selectable](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310641609/110310641609_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Pivot Pin - End Shape Selectable

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 11 Day(s)

11 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Shaft Dia. D(mm) |

| Environmentally friendly |

| Mounting Method |

| Characteristics/Applications |

| Basic Shape |

| Material |

| Hardness |

| Surface Treatment |

| Material Details |

| Cleaning Method |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI |

| Product Series | |||||||||

| CAD |

|

|

|

|

|

|

|

|

|

| From | |||||||||

| Days to Ship | Same day | 4 Day(s) | 7 Day(s) | 4 Day(s) | 10 Day(s) | 9 Day(s) | 4 Day(s) | 7 Day(s) | 11 Day(s) |

| Shaft Dia. D(mm) | 4 ~ 30 | 4 ~ 25 | 4 ~ 25 | 4 ~ 25 | 4 ~ 20 | 4 ~ 25 | 6 ~ 25 | 4 ~ 25 | 4 ~ 20 |

| Environmentally friendly | - | - | - | - | - | RoHS Compliant (10 Substances) | - | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) |

| Mounting Method | Nut (Threaded) | Nut (Threaded) | Nut (Threaded) | Nut (Threaded) | Nut (Threaded) | Nut (Threaded) | Nut (Threaded) | Nut (Threaded) | Nut (Threaded) |

| Characteristics/Applications | - | - | - | - | - | Clean Washed ~ Vacuum | - | Clean Washed ~ Vacuum | Clean Washed ~ Vacuum |

| Basic Shape | Shouldered | Shouldered | Shouldered | Shouldered | Shouldered / Straight | Shouldered | Straight | Shouldered | Shouldered / Straight |

| Material | Steel / Stainless Steel | Steel / Stainless Steel | Steel / Stainless Steel | Steel / Stainless Steel | Steel / Stainless Steel | Stainless Steel | Steel / Stainless Steel | Stainless Steel | Stainless Steel |

| Hardness | Not Spec-designed / Hardness Spec-designed | Not Spec-designed / Hardness Spec-designed | Not Spec-designed / Hardness Spec-designed | Not Spec-designed / Hardness Spec-designed | Not Spec-designed / Hardness Spec-designed | Not Spec-designed | Not Spec-designed / Hardness Spec-designed | Not Spec-designed | Not Spec-designed |

| Surface Treatment | Not Provided / Black Oxide / Electroless Nickel Plating / Hard Chrome Plating | Not Provided / Black Oxide / Electroless Nickel Plating / Hard Chrome Plating | Not Provided / Black Oxide / Electroless Nickel Plating | Not Provided / Black Oxide | Not Provided / Black Oxide / Electroless Nickel Plating / Hard Chrome Plating | Not Provided | Not Provided / Black Oxide | Not Provided | Not Provided |

| Material Details | - | - | - | - | - | SUS304 | - | SUS304 Equivalent | SUS304 |

| Cleaning Method | - | - | - | - | - | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | - | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning |

Loading...

Related Categories to Hinge Pins

FAQ Hinge Pins

- Question: What are hinge pins used for?

- Answer: Hinge pins are crucial components used to facilitate the rotation or pivot of connected parts in various machinery and equipment. They serve as pivot points, allowing for smooth and controlled rotational movement, commonly used in automation components and mechanical assemblies.

- Question: What types of hinge pins are available?

- Answer: Hinge pins are available in various types to suit different applications, including:

• Straight Hinge Pins: Simple, straight pins used for general applications.

• Shouldered Hinge Pins: Feature a shoulder to limit axial movement.

• Cotter Pin Hinge Pins: Designed for easy fixing with a cotter pin.

• Retaining Ring Hinge Pins: Secure with retaining rings to prevent axial movement.

• Threaded Hinge Pins: Include a nut or threaded section for secure fastening.

• Set Screw Hinge Pins: Include a flat or groove for set screws to secure them in place. - Question: How do I select the right hinge pin?

- Answer: When selecting hinge pins, consider the following factors:

• Shaft Diameter (D): Ensure the pin matches the diameter of the shaft or hole.

• Mounting Method: Choose based on how the pin will be secured (e.g., retaining ring, cotter pin, threaded).

• Material: Select from steel, stainless steel, or other materials based on the required strength and corrosion resistance.

• Surface Treatment: Options include black oxide, electroless nickel plating, or hard chrome plating for enhanced durability and corrosion resistance.

• Hardness: Determine if a specific hardness specification is required for your application. - Question: What materials are hinge pins made from?

- Answer: Hinge pins are typically made from materials such as:

• Steel: Offers high strength and durability, suitable for most applications.

• Stainless Steel: Provides excellent corrosion resistance, ideal for harsh environments or applications requiring high cleanliness. - Question: Why is surface treatment important for hinge pins?

- Answer: Surface treatments enhance the durability and performance of hinge pins. Common treatments include:

• Black Oxide: Provides moderate corrosion resistance and a dark finish.

• Electroless Nickel Plating: Offers superior corrosion resistance and a smooth surface.

• Hard Chrome Plating: Provides excellent wear resistance and a hard surface, extending the life of the hinge pin. - Question: How should hinge pins be maintained?

- Answer: To ensure the longevity and performance of hinge pins:

• Regular Inspection: Check for signs of wear, corrosion, or damage.

• Proper Lubrication: Apply appropriate lubricants to reduce friction and wear.

• Cleaning: Keep hinge pins clean from dirt and debris, especially in precision applications. - Question: Can hinge pins be customized?

- Answer: Yes, hinge pins can be customized in terms of diameter, length, material, and surface treatment to meet specific application requirements. Options for customization include selecting specific diameter tolerances, end shapes, and mounting methods.

- Question: What are the potential issues with improper hinge pin selection?

- Answer: Improper selection of hinge pins can lead to:

• Misalignment: Resulting in increased wear and operational inefficiency.

• Insufficient Strength: Leading to failure under load.

• Corrosion: Reducing the lifespan if the material or surface treatment is not suitable for the environment.

![[Clean & Pack] Pivot Pin - Hex Socket, Shouldered, Lock Nut](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310641429/110310641429_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Pivot Pin - Shouldered, Lock Nut](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310641339/110310641339_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Pivot Pin - End Shape Selectable](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310641609/110310641609_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Pivot Pin - Hex Socket, Shouldered, Lock Nut](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/v1/p/jp/product/series/110310641429/110310641429_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack] Pivot Pin - Shouldered, Lock Nut](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/v1/p/jp/product/series/110310641339/110310641339_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack] Pivot Pin - End Shape Selectable](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/v1/p/jp/product/series/110310641609/110310641609_001_20230911105917.jpg?$product_view_c$)

How can we improve?

How can we improve?