(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

Other Cylinders

Special cylinders are cylinders with a shape or application that is different from a regular cylinder. For example, the ultra-compact cartridge cylinder is threaded on the outer diameter to facilitate mounting onto a jig or panel; the low friction cylinder can be operated across a wide range of drive conditions, such as pressure or speed; and the precision cylinder is equipped with an internal guide function. The applications and locations of use of special cylinders vary according to type. In many cases, these cylinders are introduced in order to improve efficiency, such as saving space or improving maintainability, reducing work times or making production line operations smoother. To enable a flexible response to highly specialized requirements, special cylinders are also available whose specifications can be specified in detail, such as the type and quantity of screws and switches, and whether additional functions are equipped.

Configure

Specification/Dimensions

-

Cylinder I.D: D(Ø)

-

Stroke: L(mm)

- 1

- 1,000

- 1,002

- 1,003

- 1,005

- 1,010

- 1,020

- 1,025

- 1,030

- 1,035

- 1,041

- 1,050

- 1,060

- 1,070

- 1,080

- 1,083

- 1,090

- 1,100

- 1,110

- 1,115

- 1,120

- 1,125

- 1,127

- 1,130

- 1,135

- 1,140

- 1,145

- 1,150

- 1,155

- 1,170

- 1,180

- 1,190

- 1,200

- 1,210

- 1,220

- 1,230

- 1,250

- 1,255

- 1,260

- 1,270

- 1,290

- 1,295

- 1,300

- 1,303

- 1,310

- 1,320

- 1,323

- 1,340

- 1,350

- 1,355

- 1,370

- 1,380

- 1,400

- 1,420

- 1,430

- 1,450

- 1,460

- 1,470

- 1,500

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 10/5

- 11

- 12

- 12/6

- 13

- 14

- 15

- 15/5

- 15/8

- 15/9

- 15/10

- 15/12

- 16

- 17

- 18

- 19

- 20

- 20/5

- 20/6

- 20/9

- 20/10

- 20/11

- 20/12

- 20/13

- 20/14

- 20/15

- 20/19

- 21

- 22

- 24

- 24/12

- 25

- 25/5

- 25/6

- 25/7

- 25/8

- 25/9

- 25/10

- 25/11

- 25/12

- 25/13

- 25/14

- 25/15

- 25/16

- 25/17

- 25/18

- 25/19

- 25/20

- 25/21

- 25/22

- 25/23

- 25/24

- 26

- 27

- 28

- 29

- 30

- 30/5

- 30/9

- 30/10

- 30/11

- 30/12

- 30/14

- 30/15

- 30/16

- 30/17

- 30/19

- 30/20

- 30/21

- 30/22

- 30/23

- 30/24

- 30/25

- 30/26

- 31

- 32

- 34

- 35

- 35/8

- 35/10

- 35/15

- 35/20

- 35/25

- 35/28

- 35/30

- 35/34

- 36

- 37

- 38

- 39

- 40

- 40/5

- 40/6

- 40/7

- 40/10

- 40/15

- 40/19

- 40/20

- 40/22

- 40/25

- 40/27

- 40/29

- 40/30

- 40/32

- 40/34

- 40/35

- 41

- 42

- 43

- 45

- 45/5

- 45/10

- 45/15

- 45/18

- 45/19

- 45/20

- 45/22

- 45/28

- 45/29

- 45/32

- 45/40

- 48

- 49

- 50

- 50/5

- 50/8

- 50/10

- 50/11

- 50/12

- 50/13

- 50/14

- 50/15

- 50/16

- 50/17

- 50/18

- 50/20

- 50/21

- 50/22

- 50/23

- 50/24

- 50/25

- 50/26

- 50/27

- 50/30

- 50/32

- 50/33

- 50/34

- 50/35

- 50/36

- 50/38

- 50/39

- 50/40

- 50/41

- 50/42

- 50/43

- 50/45

- 50/47

- 50/48

- 50/49

- 51

- 52

- 54

- 55

- 55/5

- 55/10

- 55/15

- 55/20

- 55/25

- 55/26

- 55/35

- 55/40

- 55/50

- 56

- 58

- 60

- 60/5

- 60/10

- 60/15

- 60/16

- 60/20

- 60/25

- 60/30

- 60/35

- 60/37

- 60/38

- 60/40

- 60/42

- 60/45

- 60/50

- 60/55

- 63

- 64

- 65

- 65/25

- 65/27

- 65/28

- 65/30

- 65/31

- 65/35

- 65/38

- 65/40

- 65/45

- 66

- 67

- 70

- 70/10

- 70/15

- 70/35

- 70/38

- 70/39

- 70/40

- 70/47

- 70/50

- 70/55

- 72

- 75

- 75/5

- 75/6

- 75/10

- 75/15

- 75/16

- 75/18

- 75/20

- 75/21

- 75/22

- 75/23

- 75/24

- 75/25

- 75/26

- 75/27

- 75/29

- 75/30

- 75/31

- 75/32

- 75/33

- 75/35

- 75/36

- 75/37

- 75/38

- 75/39

- 75/40

- 75/41

- 75/42

- 75/43

- 75/45

- 75/46

- 75/47

- 75/48

- 75/50

- 75/52

- 75/53

- 75/54

- 75/55

- 75/57

- 75/58

- 75/60

- 75/62

- 75/63

- 75/65

- 75/66

- 75/67

- 75/68

- 75/69

- 75/70

- 75/71

- 75/73

- 75/74

- 76

- 77

- 80

- 80/12

- 80/15

- 80/26

- 80/30

- 80/35

- 80/40

- 80/42

- 80/50

- 80/55

- 80/57

- 80/60

- 80/70

- 80/71

- 80/72

- 80/73

- 80/74

- 80/75

- 81

- 81/65

- 82

- 84

- 85

- 85/10

- 85/15

- 85/25

- 85/30

- 85/50

- 85/60

- 85/65

- 86

- 88

- 90

- 90/10

- 90/15

- 90/20

- 90/29

- 90/30

- 90/35

- 90/37

- 90/40

- 90/42

- 90/45

- 90/50

- 90/70

- 91

- 95

- 95/23

- 95/35

- 95/40

- 95/55

- 95/65

- 95/80

- 96

- 97

- 100

- 100/5

- 100/6

- 100/7

- 100/8

- 100/9

- 100/10

- 100/11

- 100/12

- 100/14

- 100/15

- 100/16

- 100/17

- 100/20

- 100/21

- 100/23

- 100/25

- 100/26

- 100/29

- 100/30

- 100/32

- 100/33

- 100/34

- 100/35

- 100/38

- 100/40

- 100/41

- 100/42

- 100/43

- 100/45

- 100/46

- 100/47

- 100/48

- 100/50

- 100/52

- 100/53

- 100/54

- 100/55

- 100/56

- 100/58

- 100/60

- 100/65

- 100/66

- 100/70

- 100/74

- 100/75

- 100/76

- 100/77

- 100/80

- 100/81

- 100/82

- 100/84

- 100/85

- 100/88

- 100/89

- 100/90

- 100/91

- 100/92

- 100/93

- 100/94

- 100/95

- 100/98

- 100/99

- 101

- 105

- 105/30

- 105/32

- 105/40

- 105/89

- 105/90

- 109

- 110

- 110/5

- 110/26

- 110/30

- 110/42

- 110/50

- 110/55

- 110/60

- 110/65

- 110/70

- 110/72

- 110/80

- 110/85

- 110/100

- 110/105

- 111

- 112

- 114

- 115

- 115/10

- 115/15

- 115/30

- 115/35

- 115/39

- 115/50

- 115/75

- 115/100

- 120

- 120/25

- 120/30

- 120/40

- 120/60

- 120/65

- 120/70

- 120/75

- 120/78

- 120/90

- 120/96

- 120/100

- 122

- 123

- 124

- 125

- 125/5

- 125/6

- 125/8

- 125/10

- 125/13

- 125/15

- 125/19

- 125/20

- 125/25

- 125/30

- 125/35

- 125/36

- 125/37

- 125/39

- 125/40

- 125/42

- 125/43

- 125/45

- 125/50

- 125/51

- 125/52

- 125/55

- 125/56

- 125/57

- 125/60

- 125/62

- 125/63

- 125/64

- 125/65

- 125/66

- 125/68

- 125/69

- 125/70

- 125/71

- 125/73

- 125/75

- 125/79

- 125/80

- 125/81

- 125/82

- 125/84

- 125/85

- 125/90

- 125/92

- 125/94

- 125/95

- 125/100

- 125/103

- 125/104

- 125/105

- 125/107

- 125/110

- 125/113

- 125/115

- 125/116

- 125/118

- 125/120

- 126

- 127

- 130

- 130/10

- 130/20

- 130/40

- 130/42

- 130/50

- 130/65

- 130/75

- 130/100

- 130/120

- 130/125

- 133

- 135

- 135/45

- 135/50

- 135/60

- 135/75

- 135/95

- 135/100

- 137

- 140

- 140/10

- 140/20

- 140/40

- 140/42

- 140/70

- 140/90

- 140/120

- 142

- 144

- 145

- 145/20

- 145/73

- 145/75

- 145/85

- 145/95

- 145/100

- 145/125

- 150

- 150/6

- 150/10

- 150/15

- 150/16

- 150/20

- 150/23

- 150/25

- 150/27

- 150/30

- 150/32

- 150/35

- 150/39

- 150/40

- 150/42

- 150/45

- 150/48

- 150/50

- 150/54

- 150/55

- 150/56

- 150/60

- 150/65

- 150/68

- 150/70

- 150/71

- 150/73

- 150/74

- 150/75

- 150/76

- 150/77

- 150/78

- 150/80

- 150/82

- 150/85

- 150/90

- 150/93

- 150/95

- 150/98

- 150/99

- 150/100

- 150/101

- 150/105

- 150/107

- 150/110

- 150/115

- 150/117

- 150/120

- 150/121

- 150/125

- 150/130

- 150/135

- 150/136

- 150/138

- 150/140

- 150/141

- 150/145

- 152

- 155

- 155/5

- 155/10

- 155/30

- 155/50

- 155/77

- 155/95

- 156/78

- 157/56

- 158

- 160

- 160/20

- 160/40

- 160/50

- 160/56

- 160/60

- 160/78

- 160/80

- 160/90

- 160/95

- 160/100

- 160/110

- 162

- 163

- 165

- 165/60

- 165/64

- 165/79

- 165/90

- 165/110

- 165/115

- 165/145

- 165/150

- 168

- 170

- 170/27

- 170/50

- 170/70

- 170/85

- 170/90

- 170/100

- 170/105

- 170/125

- 171

- 172

- 175

- 175/8

- 175/10

- 175/15

- 175/20

- 175/24

- 175/25

- 175/30

- 175/35

- 175/40

- 175/45

- 175/50

- 175/55

- 175/56

- 175/60

- 175/63

- 175/64

- 175/65

- 175/70

- 175/71

- 175/75

- 175/77

- 175/78

- 175/80

- 175/81

- 175/85

- 175/87

- 175/90

- 175/98

- 175/100

- 175/103

- 175/105

- 175/108

- 175/110

- 175/112

- 175/115

- 175/120

- 175/125

- 175/127

- 175/130

- 175/132

- 175/134

- 175/135

- 175/139

- 175/140

- 175/143

- 175/145

- 175/150

- 175/155

- 175/160

- 175/170

- 177

- 180

- 180/20

- 180/35

- 180/55

- 180/65

- 180/69

- 180/90

- 180/115

- 180/160

- 185

- 185/66

- 185/165

- 188

- 190

- 190/30

- 190/60

- 190/80

- 190/84

- 190/95

- 190/150

- 195

- 195/15

- 200

- 200/5

- 200/8

- 200/10

- 200/12

- 200/13

- 200/14

- 200/15

- 200/20

- 200/25

- 200/30

- 200/35

- 200/40

- 200/41

- 200/45

- 200/50

- 200/51

- 200/55

- 200/60

- 200/65

- 200/66

- 200/70

- 200/71

- 200/75

- 200/78

- 200/80

- 200/89

- 200/90

- 200/95

- 200/97

- 200/98

- 200/99

- 200/100

- 200/103

- 200/110

- 200/115

- 200/118

- 200/120

- 200/121

- 200/124

- 200/125

- 200/130

- 200/135

- 200/140

- 200/145

- 200/147

- 200/150

- 200/160

- 200/170

- 200/175

- 200/180

- 200/185

- 200/190

- 200/195

- 201

- 203

- 205

- 205/85

- 205/200

- 206

- 210

- 210/25

- 210/60

- 210/82

- 210/90

- 210/100

- 210/105

- 210/150

- 210/170

- 210/174

- 210/175

- 212

- 215

- 215/50

- 215/200

- 219

- 220

- 220/20

- 220/55

- 220/100

- 220/110

- 220/160

- 220/165

- 224

- 225

- 225/10

- 225/24

- 225/55

- 225/70

- 225/75

- 225/85

- 225/100

- 225/110

- 225/125

- 225/150

- 225/200

- 230

- 230/40

- 230/50

- 230/80

- 230/115

- 230/180

- 230/200

- 234

- 235

- 235/90

- 235/117

- 235/175

- 235/215

- 238

- 240

- 240/40

- 240/120

- 240/140

- 240/150

- 240/200

- 243

- 245

- 245/40

- 245/165

- 245/200

- 245/223

- 250

- 250/9

- 250/25

- 250/35

- 250/50

- 250/60

- 250/61

- 250/63

- 250/65

- 250/70

- 250/75

- 250/76

- 250/80

- 250/83

- 250/85

- 250/89

- 250/90

- 250/95

- 250/100

- 250/105

- 250/106

- 250/110

- 250/115

- 250/120

- 250/121

- 250/125

- 250/128

- 250/130

- 250/135

- 250/140

- 250/150

- 250/158

- 250/160

- 250/165

- 250/170

- 250/175

- 250/176

- 250/180

- 250/185

- 250/187

- 250/189

- 250/190

- 250/192

- 250/195

- 250/200

- 250/203

- 250/210

- 250/220

- 250/225

- 250/230

- 250/235

- 250/240

- 250/241

- 250/245

- 251

- 252

- 253

- 254

- 255

- 255/170

- 260

- 260/10

- 260/60

- 260/100

- 260/105

- 260/110

- 260/120

- 260/140

- 260/210

- 265

- 265/10

- 265/100

- 265/150

- 265/230

- 267

- 270

- 270/20

- 270/150

- 270/155

- 270/195

- 270/230

- 270/240

- 275

- 275/160

- 275/200

- 275/210

- 275/218

- 277

- 278

- 280

- 280/82

- 280/105

- 280/110

- 280/135

- 280/140

- 280/150

- 280/180

- 280/230

- 281

- 285

- 285/45

- 285/210

- 285/235

- 285/250

- 290

- 290/10

- 290/100

- 295

- 295/220

- 295/235

- 300

- 300/5

- 300/8

- 300/10

- 300/13

- 300/20

- 300/30

- 300/35

- 300/40

- 300/50

- 300/55

- 300/60

- 300/62

- 300/70

- 300/75

- 300/80

- 300/85

- 300/88

- 300/89

- 300/90

- 300/93

- 300/97

- 300/100

- 300/108

- 300/110

- 300/111

- 300/122

- 300/123

- 300/124

- 300/125

- 300/127

- 300/130

- 300/137

- 300/140

- 300/145

- 300/150

- 300/155

- 300/156

- 300/160

- 300/165

- 300/170

- 300/174

- 300/175

- 300/180

- 300/182

- 300/185

- 300/186

- 300/190

- 300/195

- 300/200

- 300/210

- 300/215

- 300/220

- 300/225

- 300/227

- 300/230

- 300/239

- 300/240

- 300/246

- 300/250

- 300/255

- 300/260

- 300/265

- 300/270

- 300/280

- 300/285

- 300/290

- 300/295

- 300/299

- 305

- 310

- 312

- 315

- 318

- 320

- 325

- 327

- 330

- 335

- 336

- 338

- 340

- 345

- 350

- 352

- 355

- 356

- 360

- 361

- 363

- 365

- 370

- 375

- 376

- 380

- 381

- 385

- 390

- 393

- 395

- 400

- 401

- 402

- 403

- 404

- 405

- 406

- 410

- 412

- 415

- 420

- 421

- 423

- 425

- 430

- 432

- 434

- 435

- 437

- 440

- 445

- 450

- 452

- 454

- 455

- 456

- 457

- 458

- 460

- 465

- 466

- 470

- 475

- 478

- 480

- 485

- 490

- 495

- 500

- 502

- 503

- 505

- 510

- 511

- 512

- 515

- 516

- 518

- 520

- 522

- 525

- 530

- 534

- 535

- 536

- 537

- 540

- 542

- 545

- 547

- 548

- 549

- 550

- 555

- 559

- 560

- 562

- 563

- 565

- 570

- 575

- 577

- 580

- 581

- 583

- 585

- 590

- 591

- 594

- 595

- 600

- 605

- 606

- 610

- 611

- 615

- 620

- 625

- 630

- 632

- 633

- 635

- 640

- 645

- 650

- 653

- 655

- 660

- 663

- 665

- 670

- 675

- 680

- 683

- 685

- 690

- 693

- 695

- 700

- 703

- 704

- 705

- 707

- 710

- 715

- 720

- 725

- 730

- 735

- 740

- 745

- 750

- 753

- 755

- 756

- 760

- 762

- 765

- 770

- 772

- 775

- 780

- 783

- 785

- 786

- 790

- 792

- 795

- 800

- 801

- 805

- 807

- 810

- 811

- 814

- 815

- 816

- 819

- 820

- 825

- 830

- 835

- 840

- 845

- 850

- 853

- 855

- 858

- 860

- 863

- 865

- 870

- 873

- 875

- 880

- 885

- 890

- 900

- 905

- 910

- 915

- 920

- 925

- 930

- 935

- 940

- 950

- 955

- 960

- 965

- 970

- 973

- 975

- 980

- 985

- 990

- 995

- 999

- 1305

[200-1000/1mm Unit(s)]

-

Rod Operation Method

-

Main Body Shape

-

Cylinder Operation Method

-

Additional Function

- Standard

- With Brake

- With Intermediate Stop Function

- With Rod Rotation Stopper Function

- With Stroke Adjustment Function

-

Environment, Applications

- Standard

- Low Friction (Internal Resistance)

- High Speed, High Frequency

- Slow Speed

- Vacuum

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

- 1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

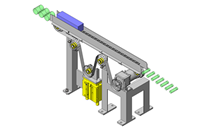

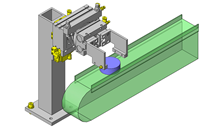

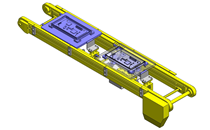

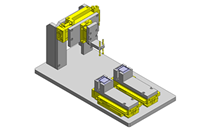

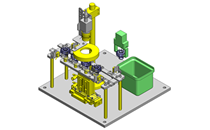

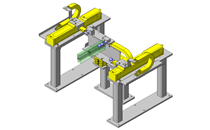

3-Position Cylinder RZQ Series

SMC

Equipped with an intermediate stop function.

[Features]

· 2-stage stroke possible by slight extension of dimensions.

· Possible to specify the first stroke without changing the total length dimension.

· Repeated intermediate stop and positioning accuracy of ±0.02 mm or lower.

· Stroke can be freely specified.

· Wide variety of mounting methods.From: ฿ 6,064.00 Days to Ship: 25 Day(s)

25 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Cylinder I.D: D(Ø) |

| Stroke: L(mm) |

| Rod Operation Method |

| Main Body Shape |

| Cylinder Operation Method |

| Additional Function |

| Environment, Applications |

You can add up to 6 items per a category to the compare list. | |

| Brand | SMC |

| Product Series | |

| CAD |

|

| From | ฿ 6,064.00 |

| Days to Ship | 25 Day(s) |

| Cylinder I.D: D(Ø) | 40 ~ 63 |

| Stroke: L(mm) | 125/92 |

| Rod Operation Method | Single-Rod |

| Main Body Shape | Block Shape |

| Cylinder Operation Method | Double Acting |

| Additional Function | With Intermediate Stop Function / With Stroke Adjustment Function |

| Environment, Applications | Standard |

Loading...

Related Categories to Other Cylinders

FAQ Other Cylinders

- Question: What are special cylinders and how do they differ from regular cylinders?

- Answer: Special cylinders are designed with unique shapes or applications that differ from standard cylinders. Examples include ultra-compact cartridge cylinders, low friction cylinders, and precision cylinders with internal guide functions. These specialized designs enhance performance in specific scenarios, such as space-saving applications or precise control environments.

- Question: How do I choose the right special cylinder for my application?

- Answer: When selecting a special cylinder, consider the following factors:

- Application Requirements: Identify the specific needs of your application, such as required motion, load capacity, and environmental conditions.

- Cylinder Type: Choose between different types such as ultra-compact, low friction, or precision cylinders based on your application.

- Mounting Options: Ensure the cylinder can be mounted properly in your system, considering options like threaded outer diameters for easy installation.

- Performance Specifications: Check for required stroke length, operating pressure, and speed compatibility. - Question: Can special cylinders be used in a variety of operating environments?

- Answer: Yes, special cylinders are designed to operate under various conditions. For instance, low friction cylinders can function efficiently across a wide range of drive conditions, including different pressures and speeds. Precision cylinders with internal guides can provide stable performance in environments requiring precise movement.

- Question: What maintenance is required for special cylinders?

- Answer: Regular maintenance for special cylinders includes checking for wear and tear, ensuring proper lubrication, and replacing seals as necessary. It's crucial to follow the manufacturer's maintenance schedule to ensure long-term performance and reliability.

- Question: Are there adjustable features in special cylinders to suit different applications?

- Answer: Many special cylinders come with adjustable features. For example, some models have built-in cushions to reduce noise and impact at the end of the stroke. Others may include adjustable speed controls or stroke adjustments to fine-tune performance for specific tasks.

- Question: How do I control the speed and position of a special cylinder?

- Answer: Speed can be controlled using flow control valves, which manage the air flow exiting the cylinder. Position can be monitored using cylinder position switches, which are essential for automated operations to ensure the cylinder has reached its desired position. For more advanced applications, integrating position sensors can provide real-time feedback and precise control.

- Question: Can special cylinders be used in custom and high-precision applications?

- Answer: Yes, special cylinders are often used in custom applications where high precision is required. For example, precision cylinders with internal guide functions are ideal for applications demanding accurate movement and minimal deflection. Custom designs can also be created to meet specific operational needs.

- Question: What are the benefits of using low friction cylinders?

- Answer: Low friction cylinders offer several advantages, including:

- Smooth Operation: They ensure smooth and uniform movement, even at low pressures and speeds.

- Reduced Wear: The low friction design reduces wear on the cylinder components, extending their lifespan.

- Precision Control: They provide precise control over the cylinder's output, making them suitable for delicate applications. - Question: How do special cylinders improve efficiency in industrial applications?

- Answer: Special cylinders are designed to enhance operational efficiency by providing solutions tailored to specific needs. For instance:

- Space-Saving Designs: Ultra-compact cylinders reduce the space required for installation.

- Enhanced Performance: Low friction and precision cylinders ensure consistent performance and reduced downtime.

- Versatility: Special cylinders can be adapted to various applications, from high-speed operations to precise positioning tasks.

How can we improve?

How can we improve?