(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

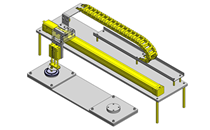

General Purpose Cylinders(Stroke: L:1,208)

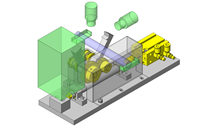

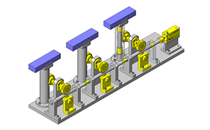

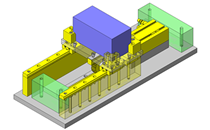

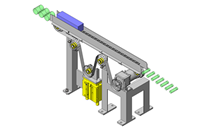

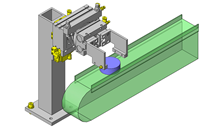

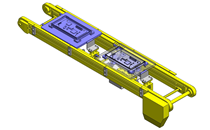

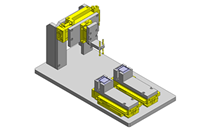

Common cylinders are parts that take the form of a cylindrically shaped container with a fluid sealed inside. They are major components in machinery such as internal combustion engines and steam engines. A piston moves in a reciprocating motion inside the container. Cylinders are used for applications requiring functions such as multi-point positioning, emergency stops or fall prevention. Example uses include moving objects onto conveyors, and opening/closing workpiece locks or hoppers. When selecting a cylinder model, criteria such as the cylinder's drive direction, speed and size should be considered along with the load movement distance, operating temperature range and operating environment.

Configure

Specification/Dimensions

-

Cylinder I.D: D(Ø)

-

Stroke: L(mm)

- 1

- 1,000

- 1,001

- 1,002

- 1,004

- 1,005

- 1,006

- 1,009

- 1,010

- 1,015

- 1,016

- 1,020

- 1,025

- 1,027

- 1,030

- 1,035

- 1,040

- 1,041

- 1,042

- 1,045

- 1,048

- 1,050

- 1,053

- 1,055

- 1,060

- 1,061

- 1,065

- 1,067

- 1,070

- 1,072

- 1,074

- 1,075

- 1,079

- 1,080

- 1,085

- 1,090

- 1,092

- 1,095

- 1,099

- 1,100

- 1,102

- 1,105

- 1,110

- 1,111

- 1,112

- 1,113

- 1,115

- 1,120

- 1,125

- 1,130

- 1,135

- 1,136

- 1,140

- 1,143

- 1,145

- 1,148

- 1,150

- 1,151

- 1,155

- 1,159

- 1,160

- 1,165

- 1,168

- 1,170

- 1,171

- 1,175

- 1,179

- 1,180

- 1,185

- 1,187

- 1,190

- 1,195

- 1,199

- 1,200

- 1,201

- 1,205

- 1,208

- 1,210

- 1,212

- 1,215

- 1,218

- 1,219

- 1,220

- 1,221

- 1,225

- 1,227

- 1,230

- 1,235

- 1,240

- 1,242

- 1,245

- 1,250

- 1,251

- 1,252

- 1,255

- 1,256

- 1,257

- 1,258

- 1,260

- 1,265

- 1,266

- 1,270

- 1,275

- 1,280

- 1,285

- 1,290

- 1,295

- 1,297

- 1,298

- 1,300

- 1,306

- 1,310

- 1,315

- 1,318

- 1,320

- 1,325

- 1,330

- 1,335

- 1,340

- 1,345

- 1,350

- 1,351

- 1,352

- 1,355

- 1,360

- 1,365

- 1,370

- 1,371

- 1,375

- 1,380

- 1,385

- 1,388

- 1,390

- 1,400

- 1,405

- 1,410

- 1,415

- 1,420

- 1,425

- 1,430

- 1,432

- 1,437

- 1,440

- 1,442

- 1,445

- 1,446

- 1,448

- 1,450

- 1,455

- 1,460

- 1,465

- 1,470

- 1,475

- 1,480

- 1,485

- 1,486

- 1,490

- 1,500

- 1,501

- 1,502

- 1,503

- 1,505

- 1,510

- 1,514

- 1,515

- 1,520

- 1,525

- 1,530

- 1,535

- 1,540

- 1,545

- 1,550

- 1,552

- 1,555

- 1,560

- 1,569

- 1,570

- 1,575

- 1,580

- 1,585

- 1,590

- 1,600

- 1,606

- 1,610

- 1,620

- 1,625

- 1,630

- 1,640

- 1,645

- 1,650

- 1,660

- 1,670

- 1,680

- 1,685

- 1,688

- 1,690

- 1,700

- 1,710

- 1,720

- 1,730

- 1,735

- 1,740

- 1,750

- 1,755

- 1,760

- 1,765

- 1,770

- 1,775

- 1,780

- 1,790

- 1,800

- 1,810

- 1,830

- 1,850

- 1,880

- 1,900

- 1,910

- 1,935

- 1,950

- 1,960

- 2

- 2,000

- 2,050

- 2,100

- 2,150

- 2,160

- 2,200

- 2,220

- 2,230

- 2,250

- 2,270

- 2,290

- 2,300

- 2,340

- 2,350

- 2,370

- 2,400

- 2,500

- 2,508

- 2,600

- 2,610

- 2,620

- 2,640

- 2,650

- 2,700

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238

- 239

- 240

- 241

- 242

- 243

- 244

- 245

- 246

- 247

- 248

- 249

- 250

- 251

- 252

- 253

- 254

- 255

- 256

- 257

- 258

- 259

- 260

- 261

- 262

- 263

- 264

- 265

- 266

- 267

- 268

- 269

- 270

- 271

- 272

- 273

- 274

- 275

- 276

- 277

- 278

- 279

- 280

- 281

- 282

- 283

- 284

- 285

- 286

- 287

- 288

- 289

- 290

- 291

- 292

- 293

- 294

- 295

- 296

- 297

- 298

- 299

- 300

- 301

- 302

- 303

- 304

- 305

- 306

- 307

- 308

- 309

- 310

- 311

- 312

- 313

- 314

- 315

- 316

- 317

- 318

- 319

- 320

- 321

- 322

- 323

- 324

- 325

- 326

- 327

- 328

- 329

- 330

- 331

- 332

- 333

- 334

- 335

- 336

- 337

- 338

- 339

- 340

- 341

- 342

- 343

- 344

- 345

- 346

- 347

- 348

- 349

- 350

- 351

- 352

- 353

- 354

- 355

- 356

- 357

- 358

- 359

- 360

- 361

- 362

- 363

- 364

- 365

- 366

- 367

- 368

- 369

- 370

- 371

- 372

- 373

- 374

- 375

- 376

- 377

- 378

- 380

- 381

- 382

- 383

- 384

- 385

- 386

- 387

- 388

- 390

- 391

- 392

- 393

- 394

- 395

- 396

- 397

- 398

- 399

- 400

- 401

- 402

- 403

- 404

- 405

- 406

- 407

- 408

- 409

- 410

- 411

- 412

- 413

- 414

- 415

- 416

- 417

- 418

- 419

- 420

- 421

- 422

- 424

- 425

- 426

- 427

- 428

- 429

- 430

- 431

- 432

- 433

- 435

- 436

- 437

- 438

- 440

- 441

- 442

- 443

- 444

- 445

- 447

- 449

- 450

- 451

- 452

- 453

- 454

- 455

- 456

- 457

- 458

- 460

- 462

- 463

- 464

- 465

- 466

- 467

- 469

- 470

- 471

- 472

- 473

- 474

- 475

- 476

- 480

- 481

- 482

- 483

- 484

- 485

- 487

- 488

- 490

- 491

- 492

- 493

- 494

- 495

- 496

- 499

- 500

- 501

- 502

- 503

- 504

- 505

- 506

- 507

- 508

- 509

- 510

- 512

- 513

- 514

- 515

- 516

- 517

- 518

- 520

- 522

- 523

- 524

- 525

- 526

- 527

- 528

- 530

- 532

- 533

- 534

- 535

- 538

- 539

- 540

- 541

- 542

- 543

- 544

- 545

- 546

- 547

- 548

- 550

- 551

- 552

- 553

- 554

- 555

- 556

- 557

- 558

- 559

- 560

- 561

- 562

- 563

- 564

- 565

- 566

- 568

- 570

- 571

- 572

- 574

- 575

- 576

- 578

- 580

- 581

- 582

- 583

- 584

- 585

- 586

- 587

- 588

- 589

- 590

- 591

- 592

- 593

- 594

- 595

- 596

- 598

- 599

- 600

- 601

- 602

- 603

- 604

- 605

- 606

- 607

- 608

- 609

- 610

- 611

- 612

- 613

- 615

- 616

- 619

- 620

- 621

- 622

- 623

- 624

- 625

- 626

- 627

- 630

- 632

- 634

- 635

- 638

- 640

- 641

- 642

- 644

- 645

- 646

- 647

- 648

- 650

- 652

- 653

- 654

- 655

- 656

- 657

- 658

- 659

- 660

- 662

- 663

- 664

- 665

- 666

- 667

- 668

- 670

- 672

- 673

- 675

- 676

- 677

- 678

- 680

- 685

- 686

- 688

- 690

- 691

- 692

- 693

- 694

- 695

- 696

- 699

- 700

- 701

- 704

- 705

- 706

- 707

- 708

- 710

- 711

- 715

- 716

- 719

- 720

- 722

- 724

- 725

- 727

- 730

- 735

- 736

- 737

- 738

- 740

- 742

- 744

- 745

- 747

- 748

- 749

- 750

- 752

- 753

- 754

- 755

- 756

- 757

- 758

- 760

- 762

- 764

- 765

- 768

- 769

- 770

- 771

- 772

- 773

- 775

- 777

- 779

- 780

- 783

- 785

- 787

- 788

- 789

- 790

- 791

- 792

- 794

- 795

- 800

- 801

- 802

- 803

- 805

- 806

- 807

- 808

- 810

- 811

- 812

- 813

- 814

- 815

- 816

- 819

- 820

- 821

- 823

- 825

- 827

- 830

- 831

- 832

- 833

- 834

- 835

- 838

- 839

- 840

- 843

- 844

- 845

- 849

- 850

- 851

- 853

- 854

- 855

- 856

- 858

- 860

- 863

- 864

- 865

- 870

- 872

- 873

- 874

- 875

- 880

- 885

- 886

- 888

- 890

- 892

- 895

- 898

- 900

- 901

- 903

- 905

- 906

- 908

- 910

- 914

- 915

- 920

- 921

- 922

- 923

- 925

- 926

- 928

- 930

- 931

- 932

- 933

- 934

- 935

- 938

- 939

- 940

- 942

- 943

- 944

- 945

- 947

- 950

- 951

- 952

- 954

- 955

- 956

- 957

- 958

- 959

- 960

- 962

- 963

- 964

- 965

- 970

- 974

- 975

- 976

- 978

- 979

- 980

- 985

- 988

- 989

- 990

- 994

- 995

- 997

- 998

- 999

- 1000

- 1172

- 1254

- 1305

- 1395

- 1435

- 1452

- 1800

[400-1000/1mm Unit(s)]

-

Rod Operation Method

-

Main Body Shape

-

Cylinder Operation Method

-

Additional Function

- Standard

- High Rigidity, High Precision, High-Grade Guide

- With Fall Prevention Mechanism

- With Brake

- With Intermediate Stop Function

- With Rod Rotation Stopper Function

- With Speed Adjustment Function

- With Cylinder Thrust Force Doubling Function

- With Stroke Adjustment Function

- Dual Stroke

-

Environment, Applications

- Standard

- Low Friction (Internal Resistance)

- High Speed, High Frequency

- Slow Speed

- Heat Resistant

- No Copper, fluoropolymer Type Material (Partially Plated)

- Clean Room

- Non-use of Copper-zinc Material

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

- 1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

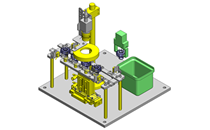

Until 31/03/2025Air Cylinder, Standard Type, Double Acting, Single Rod CG1 Series

SMC

Air cylinder with female rod end available as standard.

[Features]

· Improved auto switch operability.

· Easy to adjust position.

· No trunnion mounting female thread added to basic type variation.

· Part numbers are set for products with rod-end brackets and pivot brackets. (No need to order separately.)

*See the manufacturer's catalog for detailed specifications.

*Product pictures are representations. CAD data is not supported for some model numbers.From: ฿ 20,586.54 Special Price Days to Ship: 26 Day(s)

26 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Cylinder I.D: D(Ø) |

| Stroke: L(mm) |

| Rod Operation Method |

| Main Body Shape |

| Cylinder Operation Method |

| Additional Function |

| Environment, Applications |

You can add up to 6 items per a category to the compare list. | |

| Brand | SMC |

| Product Series | Air Cylinder, Standard Type, Double Acting, Single Rod CG1 Series |

| CAD |

|

| From | ฿ 20,586.54 Special Price On Sale Until 31/03/2025 |

| Days to Ship | 26 Day(s) |

| Cylinder I.D: D(Ø) | 63 |

| Stroke: L(mm) | 1,208 |

| Rod Operation Method | Single-Rod |

| Main Body Shape | Standard |

| Cylinder Operation Method | Double Acting |

| Additional Function | Standard |

| Environment, Applications | Standard |

Loading...

Related Categories to General Purpose Cylinders

FAQ General Purpose Cylinders

- Question: What are General Purpose Cylinders used for?

- Answer: General Purpose Cylinders are essential components in machinery that use a piston within a cylindrical container to create linear motion. They are commonly used in applications such as moving objects onto conveyors, opening and closing workpiece locks, or providing precise positioning for various mechanical tasks.

- Question: How do I choose the right General Purpose Cylinder for my application?

- Answer: To select the right cylinder, consider factors such as the required cylinder diameter (I.D.), stroke length, operating environment, and specific functions like speed control or positioning accuracy. Ensuring these specifications match your application will help in choosing the most suitable cylinder.

- Question: What types of materials are used in General Purpose Cylinders?

- Answer: General Purpose Cylinders can be made from a variety of materials including stainless steel for high corrosion resistance, aluminum for lightweight applications, and durable plastics for low-cost solutions. The choice of material depends on the environmental conditions and performance requirements.

- Question: What are the different configurations available for General Purpose Cylinders?

- Answer: Configurations include single-acting and double-acting cylinders, cylinders with different rod diameters, and those equipped with features like fall prevention, speed adjustment, or non-rotating rods. These configurations offer flexibility for diverse mechanical and industrial applications.

- Question: How do I ensure the cylinder I choose is suitable for my environment?

- Answer: Assess the operating temperature range, exposure to chemicals, and moisture levels in your environment. Choose cylinders with appropriate material coatings and seals that can withstand these conditions to ensure reliable performance and longevity.

- Question: Can General Purpose Cylinders be used for high-speed applications?

- Answer: Yes, some cylinders are designed specifically for high-speed and high-frequency operations. These typically feature low internal resistance and high-quality seals to handle rapid movement and frequent cycling without compromising performance or durability.

- Question: How do I maintain General Purpose Cylinders for long-term use?

- Answer: Regular maintenance includes checking for wear and tear, ensuring all seals and fittings are intact, and lubricating moving parts as needed. It's also important to follow the manufacturer's guidelines for cleaning and inspecting the cylinder to prevent contamination and ensure consistent performance.

- Question: What are the benefits of using double-acting cylinders over single-acting ones?

- Answer: Double-acting cylinders provide force in both directions, allowing for greater control and efficiency in applications requiring bidirectional movement. This makes them ideal for tasks such as precision positioning, automated processes, and applications that need continuous force in multiple directions.

- Question: What should I consider when selecting the stroke length for my cylinder?

- Answer: The stroke length should match the maximum distance your application requires the piston to travel. Consider the space available in your setup and the specific movement needed. Over-sizing the stroke can lead to unnecessary cost and space usage, while under-sizing can limit functionality.

- Question: Are there specific cylinders for cleanroom or high-temperature environments?

- Answer: Yes, there are cylinders specifically designed for cleanroom environments with non-corrosive materials and special seals to prevent contamination. High-temperature cylinders are made with materials and coatings that can withstand elevated temperatures, ensuring reliable performance in such conditions.

How can we improve?

How can we improve?