(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 to 20:30 19/5/2024. We apologize for the inconvenience.

- แจ้งวันหยุดทำการในเดือน พฤษภาคม 2567 | Notice holiday in May 2024 > คลิก

Timing Belt(Belt Series:AT5)

Configure

Specification/Dimensions

-

Belt Series

-

Belt Shape

-

Nominal Width W (mm)(mm)

-

Belt Material

- Rubber Belt

- Polyurethane Belt

-

Belt Tooth Surface

-

Core Wire Material

-

Nominal Width W (Inch)(Inch)

-

Belt Shape Type

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

- 4 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

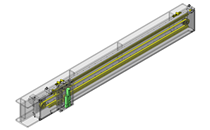

Open End Belts/Polyurethane/Chloroprene Rubber

MISUMI

Have the higher allowable tension than standard Polyurethane products and thus, are suitable for being used for stable reciprocal motions.

[Material]

· Belt (black): Chloroprene rubber, Belt (white): Polyurethane

· Core wire (belt black): Glass cord, Core wire (white belt): Steel cord

[Belt shape] Endless

[Operating temperature] -20 °C to 80 °C

[Related Products]

· Timing pulley Timing Pulley (L), Timing Pulley (H), Timing Pulley (T5), Timing Pulley (T10), High Torque Timing Pulley (S3M), High Torque Timing Pulley (S5M), High Torque Timing Pulley (S8M), Non-backlash timing Pulley (S8M),

· Belt guide: T5, T10, AT5, AT10 Timing Belt/Support Guides

· Timing belt Timing Belt Linear Guide Mounting Plate Set (XL/L/T5),

Timing Belt Overpressure Prevention (XL/L/H/MA3/MA5/MA8/T5/T10/AT5/AT10),

Metal Clamp Timing Belt Overpressure Prevention (XL/L/H/MA3/MA5/MA8/T5/T10/AT5/AT10),

Timing Belt Clamp Plate/Nut Tightening (XL/L/H/T5/T10),

Timing Belt Clamp Plate/Bottom Metel Short (XL/L/H/T5/T10)Days to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

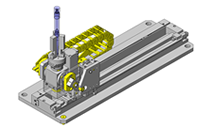

Until 31/03/2025Timing Belt Clamp Plate/Overpressure Prevention Type

MISUMI

Prevent the belt from being overtightened by touching the upper and lower metal fittings face to face.

[Material]

· Rack + holding plate: A6N01-T5

[Surface treatment]

· Clear anodize

[Accessories]

· Hexagon socket head cap bolt x 4

[Related Products]

· Timing belt

Open End Belt Iron Rubber (XL · L · H · MA3 · MA5 · MA8),

Open End Belts/Polyurethane/Chloroprene Rubber (XL · L · H · S3M · S5M · S8M)

· Belt guide: T5, T10, AT5, AT10 Timing Belt/Support GuidesFrom: ฿ 538.49 Special Price Days to Ship: 3 Day(s)

3 Day(s)

-

You can add up to 6 items per a category to the compare list.

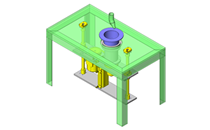

Timing Belt Clamp Plate/Overpressure Prevention/Configurable Hole Position

MISUMI

A timing belt fitting that allows you to specify the hole position according to the parts to be attached.

[Material]

· Rack: A6N01-T5

[Surface treatment]

· Clear anodize

[Related Products]

· Timing belt Open End Belt Iron Rubber (XL · L · H · MA3), Open End Belts/Polyurethane/Chloroprene Rubber (XL · L · H · S3M · S5M · S8M)

· Belt guide: T5, T10, AT5, AT10 Timing Belt/Support GuidesDays to Ship: 7 Day(s)

7 Day(s)

-

You can add up to 6 items per a category to the compare list.

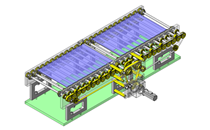

MISUMI

Have the higher allowable tension than standard Polyurethane products and thus, are suitable for being used for stable reciprocal motions.

[Material]

· Belt: Iron Rubber (Polyurethane)110302039470

· Core wire: High tensile strength steel cord

[Operating temperature] 0 °C to 80 °C

[Related Products]

· Timing pulley Timing Pulley (XL), Timing Pulley (L), Timing Pulley (H), Timing Pulley (T5), Timing Pulley (T10), Timing Pulley (AT10/AT10)

· Belt guide: T5, T10, AT5, AT10 Timing Belt/Support Guides

· Timing belt Timing Belt Linear Guide Mounting Plate Set (XL/L/T5),

Timing Belt Overpressure Prevention (XL/L/H/MA3/MA5/MA8/T5/T10/AT5/AT10),

Metal Clamp Timing Belt Overpressure Prevention (XL/L/H/MA3/MA5/MA8/T5/T10/AT5/AT10),

Timing Belt Clamp Plate/Nut Tightening (XL/L/H/T5/T10),

Timing Belt Clamp Plate/Bottom Metel Short (XL/L/H/T5/T10)Days to Ship: 5 Day(s)

5 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Belt Series |

| Belt Shape |

| Nominal Width W (mm)(mm) |

| Belt Material |

| Belt Tooth Surface |

| Core Wire Material |

| Nominal Width W (Inch)(Inch) |

| Belt Shape Type |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI | MISUMI | MISUMI |

| Product Series | Timing Belt Clamp Plate/Overpressure Prevention/Configurable Hole Position | |||

| CAD |

|

|

|

|

| From | ฿ 538.49 Special Price On Sale Until 31/03/2025 | |||

| Days to Ship | 4 Day(s) | 3 Day(s) | 7 Day(s) | 5 Day(s) |

| Belt Series | AT5 | AT5 | AT5 | AT5 |

| Belt Shape | Open End | Belt Clamp Plates | Belt Clamp Plates | Open End |

| Nominal Width W (mm)(mm) | 10 ~ 15 | 15 | 10 ~ 15 | 10 ~ 15 |

| Belt Material | Polyurethane Belt | - | - | Polyurethane Belt |

| Belt Tooth Surface | Standard (Single Sided) | - | - | Standard (Single Sided) |

| Core Wire Material | Steel Cord | - | - | Steel Cord |

| Nominal Width W (Inch)(Inch) | - | 1.5 | - | - |

| Belt Shape Type | Trapezoidal Tooth Profile Metric Type | - | - | Trapezoidal Tooth Profile Metric Type |

Loading...

Related Categories to Timing Belt

FAQ Timing Belt

- Question: How many type of Timing Belt and how to select?

- Answer: 1. Flat Belt - This belt was designed for light-duty power transmissions that don't have teeth and can operate at high speed. The cross-section of this belt is long and thin rectangular.

2. V Belt- This belt was designed for heavy-duty power transmission and can operate in low and high-speed transmission. The cross-section of this belt is trapezoid-shaped.

3. Round Belt - This belt was designed for low-power transmission and light-loading machines and smaller tasks. The cross-section of this belt is circular shaped

4. Timing Belt - This belt can operate at high and low speeds appropriate for accuracy work and can change the rotation direction while driving. This belt has many teeth shaped - Question: What is the Timing Belt drive function?

- Answer: A Timing Belt drive is a frictional drive that transmits power between two object from driver equipment such as a motor to driven components

For example

– V-Belt - This belt was used in a motor transmission system in the engine

– Timing Belt- This belt was used in an automation machine or automatic slide door system - Question: What type of Timing Belt, which popular use in manufacturing?

- Answer: In general, we can find 2 belts which commonly use in manufacturing consist of

– V- Belt: It is used in an engine, agriculture vehicle, and motor in a machine such as a Drilling machine, Milling machine, Lathe machine, Exhaust fan, and so on.

– Timing Belt: It is used in an automatic machine like CNC - Question: What kind of equipment use with Timing Belt?

- Answer: The equipment used with a Timing Belt consist of

– Pulley: This equipment was used for transmitting power from the source (rotary ) to another in a drive mechanism and sometimes use to change the alignment of the belt

– Belt Tension: This equipment is used for adjusting the belt tension

– Timing Belt Clamp Plates This equipment is used for connecting the timing belt open end type - Question: Material of Timing Belt?

- Answer: The material of a Timing Belt typically consists of several components:

1. Rear rubber: Chloroprene rubber

2. Tooth Rubber: Chloroprene rubber

3. Core wire: Glass Fiber

4. Backing cloth (Tooth Fabric): Nylon canvas

Additionally, some timing belts are made from Rubber and others from Polyurethane. The tooth rubber often adopts chloroprene to protect the core wire from dirt, grease, and wet environments.

How can we improve?

How can we improve?