(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

Photoelectric Sensors, Fiber Sensors(Head Shape:Pipe Fitting)

Search by specifying the lower class category

-

Photoelectric Sensors

Photoelectric Sensors

-

Laser Sensor

Laser Sensor

-

Fiber Units

Fiber Units

-

Fiber Sensors (Amplifiers)

Fiber Sensors (Amplifiers)

-

Lens for Sensor (for Photoelectric Sensors and Fiber Sensors)

Lens for Sensor (for Photoelectric Sensors and Fiber Sensors)

Configure

Specification/Dimensions

-

Detection Distance(mm)

- 0-3M

- 0~4

- 0~15

- 0.1-3m

- 0.1-2.5m

- 1,000

- 1~15

- 1~30

- 2~6

- 3~50

- 5

- 5~15

- 5~30

- 5.4~9

- 6

- 8~20

- 10

- 10 ± 2

- 10~20

- 10~250

- 12

- 12~30

- 15

- 15m

- 15~38

- 16

- 17

- 20~100mm

- 27

- 30

- 30±3

- 30 ± 5

- 30~200

- 30~300

- 35 ± 5

- 35~200mm

- 50

- 50~3000

- 60

- 70 ± 10

- 100

- 100mm

- 110

- 120

- 130

- 140

- 150

- 150~1500

- 180

- 190

- 200

- 200-3,000

- 220

- 250

- 280

- 300

- 300mm

- 350

- 360

- 400

- 450

- 500

- 550

- 600

- 680

- 800

- 900

- 1000

- 1100

- 1200

- 1350

- 1500

- 1550

- 1700

- 1780

- 1800

- 2000

- 2000mm

- 2600

- 2700

- 2800

- 3000

- 3500

- 3800

- 4000

- 5000

- 20000

- 30000

- 40000

The detecting distance can vary with your amplifier, operating environment and the detected object.

-

Type

- Photoelectric Sensor

- Laser Sensor

- Fiber Unit

- Fiber Sensor (Amplifier)

- Lens for Sensor

- Fiber Optic Sensor

-

Detection Type

- Transparent

- Reflection

- Liquid Surface Contact

- Recurrent Reflection

-

Light Axis Arrangement Type

- Emitting and Receiving Sections Integrated, Single

- Emitting and Receiving Sections Integrated, Reflection Plate Used

- Emitting and Receiving Sections Separated

-

Head Shape

-

Detection Light Type

-

Detection Object

- Colored Surface

- Transparent Body

- Mirror Surface Body

- Small Area

- Thin Line Shape

- Liquid Surface (Pipe Mounting)

- Liquid Surface (Contacting)

- Wafer Mapping

- Label

-

Amplifier Installation Type

- Built-in Type

- Separated Type

- Amplifier Only

-

Detection Light Color

-

Head Material

-

Detection distance 【classification】(mm)

- ~10

- ~20

- ~30

- ~50

- ~100

- ~200

- ~300

- ~400

- ~500

- ~1000

- ~2000

- ~3000

- ~4000

- ~5000

- ~10000

- More than 10000

* ~20 represents over 10, and 20 or less.

-

Operating Environment

-

Protection Structure

-

Amplifier Function (Selectable only when Amplifier is installed)

-

Fiber Type (Selectable only when Amplifier is not installed)

-

Fiber clothing material

-

Fiber minimum bend R(mm)

Brand |

|

|---|---|

Filter By |

|

| CAD |

|

| Days to Ship |

|

- 5 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

![Fiber Optic Unit [E32]](//th.misumi-ec.com/en/linked/material/mech/OMR1/PHOTO/OMR1_221000419683.jpg?$product_view_b$) Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

Until 31/03/2025OMRON

Fiber optic units for use in a variety of applications.

[Features]

· Standard types with a wide variety of shapes for use in different types of installation space.

· Types with environmental-resistance that can be used in a range of different environments.

· Types with improved detection performance that use optical technologies to reinforce the reliability of detections.From: ฿ 6,136.00 Special Price Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

Until 31/03/2025PANASONIC

[Features]·The manufacturer have achieved a reasonable price while greatly improving flexibility performance, etc.From: ฿ 4,596.67 Special Price Days to Ship: 20 Day(s)

20 Day(s)

-

You can add up to 6 items per a category to the compare list.

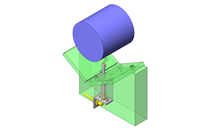

Pipe Mountable Liquid Level Sensor With Built-in Amplifier

YAMATAKE AZBIL

Liquid-level detection can become easy just by installing the product on a pipe.

[Features]

· Transmission refraction method sufficiently ensures difference of light incoming / shielding level.

· Also possible to handle liquids with low transmittance (resist solution and waste liquid).

· The outer diameter of installation pipe is ø8 to ø13 mm. For mounting method, M3 screw installation is also possible in addition to cable bundle installation.

· An indicator light and operation selector switch are positioned on the side of the unit. Making adjustments while checking the operation indicator light is easy, even during multiple mounting.

· A single model can support both upper and lower limit detection.From: ฿ 3,028.60 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

![Pipe-Mountable Liquid Level Detection Sensor [Amplifier Built-In] (EX-F1)](//th.misumi-ec.com/en/linked/material/mech/PAN1/PHOTO/221300059710_001.jpg?$product_view_b$)

Pipe-Mountable Liquid Level Detection Sensor [Amplifier Built-In] (EX-F1)

PANASONIC

Pipe-Mountable Liquid Level Detection Sensor [Amplifier Built-In] (EX-F1)

Photoelectric Sensors are a type of sensor that uses light to detect the presence or absence of an object. They offer a wide variety of type to choose from.

[Feature]

● Shape : Compact

● Applicable pipe diameter : Outer dia. ø6 to ø13 mm

● Response Time : ≤ 2ms

● Output Mode : NPN

● Detected Objects : Liquid

[Application]

Photoelectric Sensors are commonly used in industrial applications for example conveyor belts, assembly lines and so onFrom: ฿ 3,703.33 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

OPTEX FA Fiber Units NF Series Liquid Level & Liquid Leak Detection Type

OPTEX FA

Fiber units for detecting liquid

- Select based on applications for liquid level, liquid leakage, and water detection

- Array type NF-DF07 that can be mounted on ø8 to ø80 mm pipes

- A liquid accumulation prevention structure is used for all liquid level contact type models.From: ฿ 3,480.00 Days to Ship: 22 Day(s)

22 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Detection Distance(mm) |

| Type |

| Detection Type |

| Light Axis Arrangement Type |

| Head Shape |

| Detection Light Type |

| Detection Object |

| Amplifier Installation Type |

| Detection Light Color |

| Head Material |

| Detection distance 【classification】(mm) |

| Operating Environment |

| Protection Structure |

| Amplifier Function (Selectable only when Amplifier is installed) |

| Fiber Type (Selectable only when Amplifier is not installed) |

| Fiber clothing material |

| Fiber minimum bend R(mm) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | OMRON | PANASONIC | YAMATAKE AZBIL | PANASONIC | OPTEX FA |

| Product Series | Pipe-Mountable Liquid Level Detection Sensor [Amplifier Built-In] (EX-F1) | OPTEX FA Fiber Units NF Series Liquid Level & Liquid Leak Detection Type | |||

| CAD |

|

|

| ||

| From | ฿ 6,136.00 Special Price On Sale Until 31/03/2025 | ฿ 4,596.67 Special Price On Sale Until 31/03/2025 | ฿ 3,028.60 | ฿ 3,703.33 | ฿ 3,480.00 |

| Days to Ship | Same day | 20 Day(s) | Same day | Same day | 22 Day(s) |

| Detection Distance(mm) | - | - | - | - | - |

| Type | Fiber Unit | Fiber Sensor (Amplifier) | Photoelectric Sensor | Fiber Sensor (Amplifier) | Fiber Unit |

| Detection Type | Reflection | Transparent / Reflection | Transparent | Reflection | Liquid Surface Contact |

| Light Axis Arrangement Type | - | - | Emitting and Receiving Sections Integrated, Single | - | - |

| Head Shape | Pipe Fitting | Pipe Fitting | Pipe Fitting | Pipe Fitting | Pipe Fitting |

| Detection Light Type | - | - | Standard | Standard | Standard |

| Detection Object | Liquid Surface (Pipe Mounting) | - | Liquid Surface (Pipe Mounting) | Transparent Body / Liquid Surface (Pipe Mounting) | Transparent Body / Liquid Surface (Pipe Mounting) |

| Amplifier Installation Type | Separated Type | Separated Type | Built-in Type | Built-in Type | Separated Type |

| Detection Light Color | - | - | Infrared | Infrared | - |

| Head Material | - | - | - | Plastic | Plastic |

| Detection distance 【classification】(mm) | - | - | - | - | - |

| Operating Environment | Standard | - | Standard / Cold Resistant | - | Standard / Heat Resistant / Cold Resistant |

| Protection Structure | - | IP40 / IP67 | IP50 | - | - |

| Amplifier Function (Selectable only when Amplifier is installed) | - | - | Response Speed Adjustment | - | - |

| Fiber Type (Selectable only when Amplifier is not installed) | - | Flexible / Flexing Resistant | - | - | Standard |

| Fiber clothing material | - | - | - | - | Vinyl Chloride / Others |

| Fiber minimum bend R(mm) | 4 | 2 ~ 10 | - | - | 10 ~ Protective tube 20, Fiber 4 |

Loading...

Application example related to this category

Related Categories to Photoelectric Sensors, Fiber Sensors

FAQ Photoelectric Sensors, Fiber Sensors

- Question: What is the main advantage of using photoelectric sensors in industrial applications?

- Answer: Photoelectric sensors offer a significant advantage in industrial settings due to their non-contact detection capability. This feature eliminates the need for physical contact with the target object, reducing wear and tear and enabling reliable, long-term operation. Their quick response time is crucial for applications requiring rapid detection, contributing to increased efficiency in various industrial processes.

- Question: How do I choose the right photoelectric sensor?

- Answer: Selecting the appropriate photoelectric sensor involves considering several factors. Evaluate the sensing distance required for your application, environmental conditions, such as ambient light and temperature, and the characteristics of the target objects. Differentiate between through-beam, reflective, and retroreflective sensors based on the specific needs of your application.

- Question: Can these sensors be used in outdoor environments?

- Answer: Some photoelectric sensors are designed for outdoor use. It's essential to choose sensors with suitable Ingress Protection (IP) ratings to ensure they can withstand exposure to weather elements and maintain reliable performance.

- Question: What is the difference between a through-beam sensor and a reflective sensor?

- Answer: Through-beam sensors consist of separate emitter and receiver units, with the light beam traveling from one unit to the other. In contrast, reflective sensors integrate both the emitter and receiver in the same housing, detecting the light reflected off a target object.

- Question: Can photoelectric sensors detect transparent or highly reflective objects?

- Answer: Certain photoelectric sensors are specifically engineered to detect transparent or highly reflective objects. Choosing sensors with the appropriate technology, such as background suppression or polarization filters, ensures accurate detection in challenging conditions.

- Question: What maintenance do photoelectric sensors require?

- Answer: Photoelectric sensors typically demand minimal maintenance. Regularly cleaning the sensor lens to prevent the accumulation of dust or dirt is recommended to ensure consistent and accurate performance over time.

- Question: Are there any safety considerations when using photoelectric sensors?

- Answer: When using photoelectric sensors, it's crucial to ensure compliance with relevant safety standards. Installation should follow the manufacturer's guidelines, and users should be aware of the sensor's limitations. For critical applications, incorporating redundancy or additional safety measures is advisable to mitigate potential risks.

![Fiber Optic Unit [E32]](http://th.misumi-ec.com/en/linked/material/mech/OMR1/PHOTO/OMR1_221000419683.jpg?$product_view_b$)

![Pipe-Mountable Liquid Level Detection Sensor [Amplifier Built-In] (EX-F1)](http://th.misumi-ec.com/en/linked/material/mech/PAN1/PHOTO/221300059710_001.jpg?$product_view_b$)

![Fiber Optic Unit [E32]](http://th.misumi-ec.com/en/linked/material/mech/OMR1/PHOTO/OMR1_221000419683.jpg?$product_view_c$)

![Pipe-Mountable Liquid Level Detection Sensor [Amplifier Built-In] (EX-F1)](http://th.misumi-ec.com/en/linked/material/mech/PAN1/PHOTO/221300059710_001.jpg?$product_view_c$)

How can we improve?

How can we improve?