(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

Shaft Collars(Thickness:Balanced Type)

Shaft Collars products in the Automation Components category. Specified by Thickness Balanced Type. There are around 1 items of Shaft Collars products available and the specifications can easily be compared. Search and select detailed specifications of parts for your machine with free CAD downloads. Shaft Collars offers a wide selection, on time delivery free of charge and no minimum order with a consulting team available.

Configure

Specification/Dimensions

-

Specifications

-

Standard

Standard -

With Clamp Lever

With Clamp Lever -

For Bearing Mounting

For Bearing Mounting -

Urethane

Urethane -

Side Mount Hole

Side Mount Hole -

D Cut

D Cut -

2-Flats

2-Flats -

Threaded Bore

Threaded Bore -

Key Relief Groove

Key Relief Groove

-

-

I.D.

-

O.D.

- 6

- 7

- 8

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 17.2

- 18

- 18.7

- 19

- 20

- 21.7

- 22

- 23

- 24

- 24.2

- 25

- 26

- 27

- 28

- 29

- 29.2

- 30

- 31

- 32

- 33

- 33.2

- 34

- 34.5

- 35

- 35.5

- 36

- 38

- 39

- 40

- 40.2

- 41

- 42

- 44

- 45

- 46

- 46.2

- 47

- 48

- 49

- 50

- 51

- 51.5

- 52

- 52.2

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 62

- 63

- 64

- 65

- 65.4

- 66.5

- 68

- 69

- 70

- 72

- 75

- 78

- 79

- 79.5

- 80

- 81

- 83

- 85

- 86

- 88

- 90

- 94

- 95

- 105

- 110

- 113

- 115

- 119

- 126

- 130

- 135

- 140

- 150

- 170

- 180

-

Width

-

Material

- Steel

- Stainless Steel

- Aluminum

- Plastic

-

Surface Treatment

- No Surface Treatment

- Surface Treatment

-

Thickness

-

Side Hole Machining

|

Fastening Method

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

- 1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

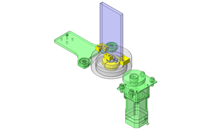

Until 31/03/2025Shaft Collar (Split) - Standard / Compact / Balanced

MISUMI

Compared to the standard type, it is up to 33% more compact in width and 16% more compact in outer diameter.From: ฿ 396.17 Special Price Days to Ship: Same day

Same day

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Fastening Method |

| Specifications |

| I.D. |

| O.D. |

| Width |

| Material |

| Surface Treatment |

| Thickness |

| Side Hole Machining |

You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI |

| Product Series | |

| CAD |

|

| From | ฿ 396.17 Special Price On Sale Until 31/03/2025 |

| Days to Ship | Same day |

| Fastening Method | Split |

| Specifications | Standard |

| I.D. | 16 ~ 50 |

| O.D. | 35 ~ 85 |

| Width | 10 ~ 22 |

| Material | Steel / Stainless Steel |

| Surface Treatment | No Surface Treatment / Surface Treatment |

| Thickness | Balanced Type |

| Side Hole Machining | Not Provided |

Loading...

Application example related to this category

Related Categories to Shaft Collars

-

- Linear Shafts

- Shaft Supports

- Shaft Collars

- Linear Bushings

- Ball Guides

- Spline Shaft

- Oil Free Bushings, Washers

- Oil Free Plates, Guide Rails

- Linear Guides

- Cable Carriers

- Ball Screw

- Support Units

- Lead Screws, Slide Screws

- Cross Roller

- Slide Packs, V Guides, Linear Rails

- Actuators

- Other Linear Motion Related Components

- Bellows

-

FAQ Shaft Collars

- Question: What are Shaft Collars and what are their main uses?

- Answer: Shaft collars are mechanical components used to position, locate, and secure components on a shaft. They serve multiple roles, such as holding bearings and sprockets, acting as mechanical stops, and situating components in motor and gearbox assemblies.

- Question: What types of Shaft Collars are available?

- Answer: There are several types of shaft collars, each suitable for different applications:

• Set Screw Collars: These use a set screw to secure the collar to the shaft. They can damage the shaft but are cost-effective and simple to use.

• One-Piece Clamp Collars: These collars wrap around the shaft and are tightened with a single screw. They do not mar the shaft and are easy to install and adjust.

• Two-Piece Clamp Collars: These collars consist of two halves that clamp around the shaft, offering easier installation and greater holding power.

They are ideal for applications where the end of the shaft is not accessible.

• Hinged Collars: These collars feature a hinge for easy installation and removal, making them suitable for applications with limited space. - Question: What materials are Shaft Collars made from?

- Answer: Shaft collars can be made from various materials, each offering different advantages:

• Steel: Provides high strength and durability.

• Stainless Steel: Offers corrosion resistance, ideal for harsh environments.

• Aluminum: Lightweight and resistant to corrosion.

• Plastic: Provides electrical insulation and resistance to chemicals. - Question: How do I choose the right Shaft Collar for my application?

- Answer: When selecting a shaft collar, consider the following factors:

• Shaft Size: Ensure the collar matches the diameter of your shaft.

• Load Requirements: Choose a collar that can handle the axial and radial loads of your application.

• Environmental Conditions: Select materials that can withstand the environmental conditions, such as corrosion or temperature extremes.

• Installation Requirements: Consider whether you need a collar that is easy to install and adjust, such as a two-piece or hinged collar. - Question: What are the advantages of Clamp Style Collars over Set Screw Collars?

- Answer: Clamp style collars offer several benefits over set screw collars:

• Non-marring: They do not damage the shaft surface, making them suitable for applications where shaft integrity is crucial.

• Adjustability: They are easy to install and adjust, allowing for precise positioning without permanent shaft damage.

• Uniform Clamping Force: They provide a more secure hold by distributing clamping forces uniformly around the shaft. - Question: Can Shaft Collars be used in high-load applications?

- Answer: Yes, shaft collars can be used in high-load applications. For such applications, consider using heavy-duty clamp collars, which provide exceptional holding power. Additionally, two-piece clamp collars can handle higher shock loads and offer more uniform holding force compared to one-piece designs.

- Question: Are there special types of Shaft Collars for specific applications?

- Answer: Yes, there are specialized shaft collars designed for specific applications, such as:

• Weldable Collars: Suitable for permanent applications where welding is required.

• Keyed Collars: Feature a keyway for additional torque transmission.

• Quick-Release Collars: Allow for fast installation and removal without tools, ideal for frequent adjustments. - Question: What considerations should be taken into account for installation and maintenance?

- Answer: When installing shaft collars:

• Ensure the shaft surface is clean and free of burrs.

• Use the appropriate torque settings for screws to avoid over-tightening.

• Regularly inspect collars for wear and replace them if necessary to maintain optimal performance.

How can we improve?

How can we improve?