(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

Shaft Supports(Hole Dia. D:10M)

Configure

Specification/Dimensions

-

Environmentally friendly

-

Shaft Securing Type

-

Set Screw

Set Screw -

Slit

Slit -

Side Slit

Side Slit -

Split

Split -

Hinged

Hinged

-

-

Characteristics/Applications

-

Hole Dia. D(Ø)

-

Material

- Steel

- Stainless Steel

- Aluminum

-

Surface Treatment

- Not Provided

- Black Oxide

- Electroless Nickel Plating

- Black Anodize

- Clear Anodize

-

Type

- Cast Product

- Machined Product

-

Flange Shape/Type

- Standard

- Long Sleeve

- Back Mount

- With Keyway

-

Material Details

- SUS304

-

Mounting Method for Block Type

-

Top Counterbored

Top Counterbored -

Side Through Hole

Side Through Hole -

Bottom Tapped Hole

Bottom Tapped Hole

-

-

Thickness

-

Dowel Hole

-

Clamp Lever

-

Cleaning Method

- Degreasing

- Precision Cleaning

- Electrolytic Polishing + Precision Cleaning

|

Shape

|

|

|---|---|

Brand |

|

Filter By |

|

| CAD |

|

| Days to Ship |

|

- 2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025

Until 31/03/2025

Until 31/03/2025Shaft Supports Flanged Mount - Standard - Standard Through/Tapped Mounting Holes / Long Sleeve

MISUMI

If the plate on the mounting side is weak or thin, we recommend the tapped mounting hole type.From: ฿ 278.00 Special Price Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025

Until 31/03/2025

Until 31/03/2025Shaft Supports Flanged Mount - Standard - With Pilot

MISUMI

Positioning during assembly becomes easier. Positioning is reproducible when removed for maintenance.From: ฿ 295.75 Special Price Days to Ship: 3 Day(s)

3 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Shape |

| Environmentally friendly |

| Shaft Securing Type |

| Characteristics/Applications |

| Hole Dia. D(Ø) |

| Material |

| Surface Treatment |

| Type |

| Flange Shape/Type |

| Material Details |

| Mounting Method for Block Type |

| Thickness |

| Dowel Hole |

| Clamp Lever |

| Cleaning Method |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI |

| Product Series | Shaft Supports Flanged Mount - Standard - Standard Through/Tapped Mounting Holes / Long Sleeve | |

| CAD |

|

|

| From | ฿ 278.00 Special Price On Sale Until 31/03/2025 | ฿ 295.75 Special Price On Sale Until 31/03/2025 |

| Days to Ship | Same day | 3 Day(s) |

| Shape | Flanged Type | Flanged Type |

| Environmentally friendly | - | - |

| Shaft Securing Type | Set Screw | Set Screw |

| Characteristics/Applications | - | - |

| Hole Dia. D(Ø) | 10M | 10M |

| Material | Steel / Stainless Steel | Steel / Stainless Steel |

| Surface Treatment | Not Provided / Black Oxide / Electroless Nickel Plating | Not Provided / Black Oxide / Electroless Nickel Plating |

| Type | Machined Product | Machined Product |

| Flange Shape/Type | Standard | Standard |

| Material Details | - | - |

| Mounting Method for Block Type | - | - |

| Thickness | Standard | Standard |

| Dowel Hole | Not Provided | Not Provided |

| Clamp Lever | Not Provided | Not Provided |

| Cleaning Method | - | - |

Loading...

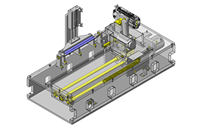

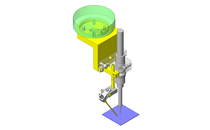

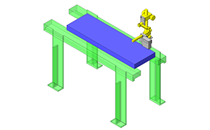

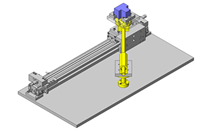

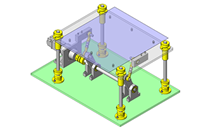

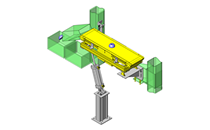

Application example related to this category

Related Categories to Shaft Supports

-

- Linear Shafts

- Shaft Supports

- Shaft Collars

- Linear Bushings

- Ball Guides

- Spline Shaft

- Oil Free Bushings, Washers

- Oil Free Plates, Guide Rails

- Linear Guides

- Cable Carriers

- Ball Screw

- Support Units

- Lead Screws, Slide Screws

- Cross Roller

- Slide Packs, V Guides, Linear Rails

- Actuators

- Other Linear Motion Related Components

- Bellows

-

FAQ Shaft Supports

- Question: What are shaft supports used for?

- Answer: Shaft supports are used to secure and support rotating shafts in various industrial applications. They provide stability, reduce vibration, and ensure precise alignment, which is critical for the optimal performance of machinery.

- Question: What types of shaft supports are available?

- Answer: Shaft supports come in several types, including:

• Set Screw Type: Secures the shaft with a screw.

• Slit Type: Uses a slit mechanism for clamping. • Side Slit Type: Similar to slit type but clamped from the side.

• Split Type: Consists of two parts that clamp the shaft from both sides. • Hinged Type: Features a hinge for easy installation and removal of the shaft. - Question: How do I select the right shaft support?

- Answer: When selecting a shaft support, consider the following factors:

• Shaft Diameter: Ensure the support matches the diameter of your shaft.

• Material: Choose between steel, stainless steel, or aluminum based on the operating environment and load requirements.

• Mounting Method: Options include top counterbored, side through hole, and bottom tapped hole, depending on your mounting surface.

• Surface Treatment: Consider treatments like black oxide, electroless nickel plating, or anodization for enhanced durability and corrosion resistance.

• Application Requirements: Determine if you need features like flanged mount, T-shaped, L-shaped, or round type supports based on your specific application needs. - Question: What is the importance of surface treatment for shaft supports?

- Answer: Surface treatments enhance the durability and corrosion resistance of shaft supports. Common treatments include:

• Black Oxide: Provides moderate corrosion resistance and an aesthetic finish.

• Electroless Nickel Plating: Offers excellent corrosion resistance and a smooth surface.

• Anodization: Common for aluminum supports, providing increased surface hardness and resistance to wear and corrosion. - Question: How do I ensure proper alignment when installing shaft supports?

- Answer: Proper alignment is crucial to prevent premature wear and failure. Use dowel holes or alignment pins if available, and ensure the mounting surface is clean and free of debris. Precision machined supports are recommended for applications requiring high accuracy.

- Question: What are the potential issues with improper shaft support selection?

- Answer: Improper selection can lead to: • Misalignment: Causing increased wear and vibration.

• Insufficient Clamping Force: Leading to shaft movement and operational instability.

• Corrosion: If the material or surface treatment is not suitable for the operating environment, it can result in premature failure. - Question: How do I maintain and service shaft supports?

- Answer: Regular maintenance involves:

• Inspection: Periodically check for signs of wear, corrosion, or misalignment.

• Lubrication: Ensure that moving parts are adequately lubricated to reduce friction.

• Cleaning: Keep the supports and surrounding areas clean from dust and debris.

• Replacement: Replace any worn or damaged supports promptly to avoid machinery downtime. - Question: Can I use shaft supports in high-temperature environments?

- Answer: Yes, but it’s important to select materials and treatments that can withstand high temperatures. Stainless steel and specific anodized aluminum supports are suitable for such conditions. Ensure that the supports are rated for the temperature range of your application.

How can we improve?

How can we improve?