(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 to 20:30 19/5/2024. We apologize for the inconvenience.

- แจ้งวันหยุดทำการในเดือน พฤษภาคม 2567 | Notice holiday in May 2024 > คลิก

NABESEI Adjuster Pads

Adjuster Pads products in the Automation Components category from NABESEI. The product can be selected based on many product specifications such as Selected Product. NABESEI offers products around 1 items and the product specifications can easily be compared. Search and select detailed specifications of parts for your machine with free CAD downloads. NABESEI products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Configure

Specification/Dimensions

|

Selected Product

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

- 1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

NABESEI

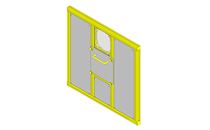

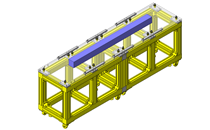

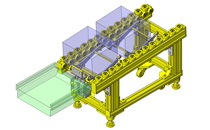

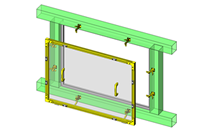

Anchor Bracket (140S, 140W)

This anchor bracket is commonly utilized to assemble aluminum extrusions. It is designed for aluminum extrusions from the SUS brand.

[Feature]

- Height (mm.) : 140

- Shape : L Type

- Type : Double holes

- Material : SS400

- Surface Treatment: Trivalent Chromate

[Application]

It is used to securely fixed aluminum frames to various surfaces, such as machine stands, safety fences, and so onFrom: ฿ 614.05 Days to Ship: 5 Day(s)

5 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Selected Product |

You can add up to 6 items per a category to the compare list. | |

| Brand | NABESEI |

| Product Series | |

| CAD |

|

| From | ฿ 614.05 |

| Days to Ship | 5 Day(s) |

| Selected Product | Anchors |

Loading...

Related Categories to Adjuster Pads

FAQ Adjuster Pads

- Question: How do you adjust adjuster pads?

- Answer: Adjusting adjuster pads, also known as adjustable feet or leveling feet, involves the following steps:

1. Locate the adjuster pads at the base of the machine.

2. Determine the desired height or levelness.

3. Use the appropriate tool to turn the adjuster mechanism for example wrench , hand crank and so on

4. Adjust the pads incrementally by each side, testing stability and levelness of machine

5. Secure the adjuster pads: Once the machine is properly leveled, ensure that the adjuster pads are securely tightened to maintain stability.

6. Refer to manufacturer instructions for specific guidance.

Note: This is a brief overview, and it's important to consult the machine's documentation for detailed instructions and safety considerations. - Question: How do you measure the thread length for adjustable leveling feet?

- Answer: Measuring the thread length for adjustable leveling feet, also known as adjuster pads or adjustable foot, is essential for proper installation and compatibility. Follow these steps to measure the thread length accurately:

1. Fully extend the leveling foot: Ensure the leveling foot is in its fully extended position, exposing the entire threaded portion.

2. Use a measuring tool: Utilize a ruler, vernier caliper, or tape measure to measure the length from the base of the foot to the end of the threaded section.

3. Take note of the size after measure : Record the measured thread length.

Note: It is important to measure accurately to ensure compatibility and proper adjustment range when selecting or replacing adjustable leveling feet. - Question: What is the purpose of adjustable machine feet?

- Answer: Adjustable machine feet, also referred to as adjuster pads, adjustable foot, or leveling feet, serve the following primary purposes:

1. Stability: Adjustable machine feet provide a stable and secure base for machines and equipment. They help prevent unnecessary movement.

2. Leveling: These feet allow for the adjustment of the machine's height and levelness. By tight a screw for raising or lowering the machine as needed, they compensate for uneven surfaces.

3. Vibration Damping: Adjustable machine feet help reduce vibrations generated by the machine during operation. They absorb and dampen vibrations, minimizing the impact on the machine and its surroundings, resulting in a quieter and more stable working environment.

4. Protection: These feet also serve to protect both the machine and the surface it rests upon. They help prevent damage to the machine by providing a cushioning effect, absorbing shocks and impacts. Additionally, they help prevent scratches, marks, and other damage to the floor or surface on which the machine is placed. - Question: What is the maximum weight that adjuster pads can take?

- Answer: The maximum weight that adjuster pads, also known as adjustable foot or leveling feet, can handle varies depending on several factors. These factors include the design and material. In Generally, adjuster pads are engineered to support heavy loads and machinery commonly found in industrial applications. However, it is essential to select adjuster pads that are suitable for the weight requirements of your specific equipment. When in doubt, consult the manufacturer or seek advice from experienced engineers to ensure the adjuster pads can safely support the intended weight. Adhering to weight limitations is crucial for maintaining stability, preventing damage to the equipment and surrounding environment, and ensuring the safe operation of the machinery.

- Question: How do you choose the right adjuster pad for your application?

- Answer: Here are step-by-step guidelines for beginner-level selection of the appropriate adjuster pad for your application.

1. Load Capacity: Determine the maximum weight or load that the adjuster pad needs to support. ฺBy considering the weight of the machine

2. Height Adjustment Range: Consider the desired height adjustment range needed for your application.

3. Thread Size: Thread Size: Verify the thread size of the adjuster pad, which should match the thread size of the machine or equipment you are working with.

4. Base Material and Design: Evaluate the material and design of the adjuster pad's base. Different materials offer varying levels of stability, durability, and resistance

5. Surface Protection: If the adjuster pad will be placed on delicate or sensitive surfaces, such as hardwood floors or finished concrete, consider using pads with additional features like rubber or cushioning to protect the surface from damage.

6. Manufacturer Recommendations: Always refer to the manufacturer's recommendations and guidelines when selecting the appropriate adjuster pad for your specific application. They can provide valuable insights regarding specific requirements or considerations.

How can we improve?

How can we improve?