(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน พฤษภาคม 2567 | Notice holiday in May 2024 > คลิก

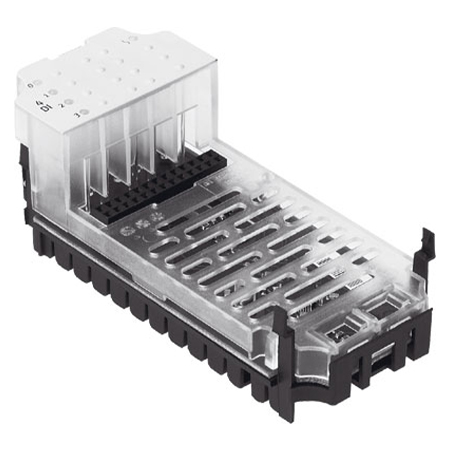

PLC (Input/Output Units)

PLCs (Input/Output Units), formally called "programmable logic controllers," are components used as an interface between devices and sequencers. They work by controlling the on/off switching of the output device using a preset program that operates in response to the on/off switching of switches and sensors. They were initially developed as an alternative to relay circuits and are used in controls for boilers, pumps, automated machinery that operate inside factories, and more. PLCs are broadly divided into 2 types, modular type and packaged type. Modular types require input components and standalone units to be combined and allow for more freedom of customization. Packaged types are totally pre-assembled to offer an inexpensive installation solution.

Configure

Specification/Dimensions

-

Number Of Inputs

-

Input Format

- DC input

- AC input

- AC/DC input

- Other

-

Rated Input Voltage(V)

- DC-10~+10

- 1~5 / 0~5 / 0~10

- 5

- DC5

- DC5V

- DC5-12

- DC5/DC12

- DC5/24

- 12 to 24

- 12–24

- DC12/24

- DC12~24

- DC 12/24

- DC13 to 30

- 18-30 DC

- 20.4-28.8 DC

- DC20.4 to 28.8

- 24

- 24 DC

- 24 V

- DC24

- DC24V

- DC 24

- DC48

- DC48/AC48

- AC100V

- AC100-120

- AC 100-120

- 100 to 120

- AC100 to 120

- AC100 to 120V

- AC100~120

- VAC 100–120

- AC100 to 240

- AC100 to 240V

- AC 100–240

- AC200-240

- 200 to 240

- AC200 to 240

- (Not applicable)

- NA

- Not available

-

Input answer time

- Less than 1 mS

- Less than 10 to 20 mS

- Less than 50 to 100 mS

- Other

-

Number of Outputs

-

Output Format

- Relay contact output

- Triac output

- Transistor / source output

- Transistor / sync output

- Other

-

Rated load voltage(V)

-

Protection function

- None

- Input protection function

- Output protection function

- Other

-

Connection Terminal

- Terminal Block

- Connector

- Terminal block/connector

- Europe terminal block

-

Representative Standard

- CE

- UL

- CUL

- TUV

- CSA

- Other

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

- 2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

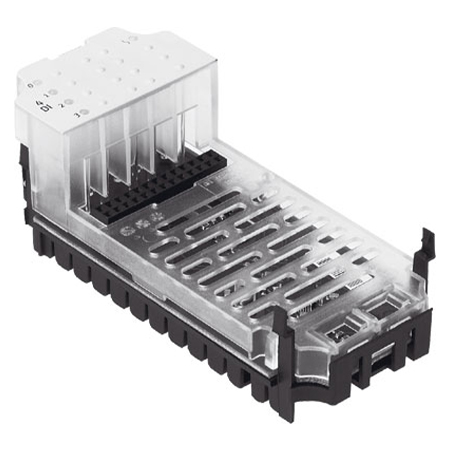

PANASONIC

Can efficiently install the required number of I/O.

[Features]

· Combined input/output unit is available

Using the combined input/output unit makes it possible to efficiently install the required number of I/O. Provides a more compact size of PLC at a lower cost.

· A current capacity of 300 mA is also installed in the transistor output unit of the 64-point output unit

8 contact points with a current capacity of 300 mA are mounted on a 64-point transistor output unit.

It is now possible to directly operate large display lights and magnetic contact points.

· Adjusting the input time constant can counteract noise

Choose from response times of 0.1 ms, 0.5 ms, 1.0 ms, 5.0 ms, 10.0 ms, 20.0 ms or 70.0 ms according to the output device used.

*The product pictured is AFP7X16DW.From: ฿ 24,150.00 Days to Ship: 40 Day(s)

40 Day(s)

-

You can add up to 6 items per a category to the compare list.

From: ฿ 20,180.07 Days to Ship: 30 Day(s)

30 Day(s)

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Number Of Inputs |

| Input Format |

| Rated Input Voltage(V) |

| Input answer time |

| Number of Outputs |

| Output Format |

| Rated load voltage(V) |

| Protection function |

| Connection Terminal |

| Representative Standard |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | PANASONIC | FESTO |

| Product Series | ||

| From | ฿ 24,150.00 | ฿ 20,180.07 |

| Days to Ship | 40 Day(s) | 30 Day(s) |

| Number Of Inputs | 32 | 16 |

| Input Format | DC input | - |

| Rated Input Voltage(V) | 24 DC | 24 DC |

| Input answer time | Less than 1 mS | - |

| Number of Outputs | 32 | - |

| Output Format | Transistor / source output | - |

| Rated load voltage(V) | - | - |

| Protection function | - | - |

| Connection Terminal | Connector | - |

| Representative Standard | CE / UL / CUL | - |

Loading...

Related Categories to PLC (Input/Output Units)

-

- PLC (CPU Units)

- PLC (Power Supply Units)

- PLC (Base Units)

- PLC (Software, Manuals)

- PLC Compatible Cables

- PLC Compatible Batteries

- PLC (Options, Others)

- PLC (Communication Units)

- PLC (Input/Output Units)

- PLC (Analog Units)

- PLC (Memory Units)

- PLC (Motion Controllers)

- PLC (Control Units)

- PLC (Wire-Saving Dedicated Units)

-

FAQ PLC (Input/Output Units)

- Question: What is a PLC (Programmable Logic Controller) and How Do Input/Output Units Function in Automated Systems?

- Answer: A PLC, or Programmable Logic Controller, is the brains behind many automated systems. It's like a specialized computer designed for controlling machines and processes. PLCs use Input/Output (I/O) units to communicate with sensors and actuators in the actual system. These I/O units serve as the interface between the digital world of the PLC and the physical world of your machines. Inputs gather data from sensors, while outputs send control signals to devices like motors and valves, allowing the PLC to make decisions and automate tasks.

- Question: How Do PLC Input/Output Units Interface with Devices and Sequencers in Industrial Automation?

- Answer: PLC I/O units interface with devices through wiring connections. Inputs are connected to sensors or switches, while outputs are linked to devices like motors, valves, or lights. The PLC's programming defines how inputs and outputs interact. For example, an input from a temperature sensor might trigger an output to turn on a cooling fan. PLCs can also work in sequence, performing a series of tasks based on inputs and previous outcomes. This sequence can be programmed to control complex industrial processes.

- Question: How Do I Install and Program PLC Input/Output Units for Optimized Control in Automated Machinery?

- Answer: Installing PLC I/O units involves mounting them in a control panel, connecting wires, and ensuring proper electrical connections. To program a PLC for optimized control, you'll use specialized software to create a logic program. This program defines how the PLC responds to different inputs and manages outputs. It's essential to understand your machinery's requirements, design a logical program, and thoroughly test it to ensure efficient and safe operation.

- Question: In Which Industrial Applications Are PLCs Commonly Used?

- Answer: PLCs are incredibly versatile and can be found in various industrial applications. They're widely used in manufacturing for tasks like assembly line control and quality assurance. They're also essential in processes like water treatment, energy production, and food production. Basically, anywhere automation and precise control are needed, you'll often find PLCs at the heart of the operation.

How can we improve?

How can we improve?