Fall Prevention Valve

Caution

Product Description

Fall‑prevention valves that curtail the vacuum reduction for pads adhering normally.

[Features]

· Even if workpieces are separated, it is possible to minimize reductions in primary pressure in other circuits.

· Prevents a workpiece that is adhering correctly from falling, even if some pads are not adhering.

[Applications]

· Ideal for assembly and installation machinery and replenishment devices, automatic packaging devices and molded part removal.

Fall Prevention Valve Specifications

Fall prevention valve external appearance

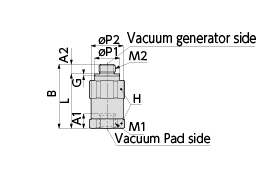

Fall prevention valve dimensional diagrams (for meter screws)

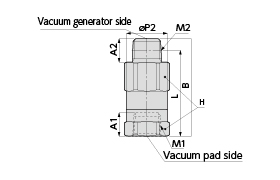

Fall prevention valve dimensional diagrams (for tapered screws for pipes)

Usable medium: Air

Operating pressure range: Positive pressure 0 to 0.7 MPa, negative pressure - 100 to 0 kPa

Minimum suction flow volume: M3-M3: 2 L/min (ANR) M4-M4, M5-M5: 5 L/min (ANR) M6-M6, M10-M10, 01-01: 13 L/min (ANR)

Operating temperature range: 0 to 60°C (no freezing)

Size table

| Format | M1 | M2 | A1 | A2 | B | L | G | ØP1 | ØP2 | Opposite Side H | Minimum Suction Volume Of Valve (I/min[ANR]) | Suction Volume of Valve After Operation (l/min[ANR]) | Effective Sectional Area (mm2) | Mass (g) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Free Flow Side | ||||||||||||||

| ECVM3-M3 | M3 × 0.5 | M3 × 0.5 | 4.5 | 2.5 | 18.4 | 15.9 | 0.5 | 5.5 | 8 | 8 | 2 | 1.3 | 0.7 | 4.9 |

| ECVM4-M4 | M4 × 0.7 | M4 × 0.7 | 4.5 | 2.9 | 19.9 | 17 | 0.6 | 7.8 | 10 | 10 | 5 | 1.3 | 1.6 | 7.9 |

| ECVM5-M5 | M5 × 0.8 | M5 × 0.8 | 4.5 | 3 | 19.9 | 16.9 | 0.5 | 7.8 | 10 | 10 | 5 | 1.3 | 1.6 | 6.6 |

| ECVM6-M6 | M6 × 1 | M6 × 1 | 5 | 4 | 28.1 | 24.1 | 0.5 | 8.8 | 12 | 12 | 13 | 1.3 | 4.0 | 13 |

| ECVM10-M10 | M10 × 1.5 | M10 × 1.5 | 10 | 7.5 | 40 | 32.5 | 2.5 | 14 | 14 | 14 | 13 | 1.3 | 4.8 | 11 |

| ECV01-01 | Rc 1/8 | R1/8 | 8 | 8 | 33.5 | 29.5 | - | - | 14 | 14 | 13 | 1.3 | 4.8 | 10 |

Units: mm

Applicable Screw Size

| Meter Male And Female Screws | M3 × 0.5, M4 × 0.7, M5 × 0.8, M6 × 1, M10 × 1.5 |

|---|---|

| Tapered Male And Female Screws For Pipes | R1/8, Rc1/8 |

Operation explanations

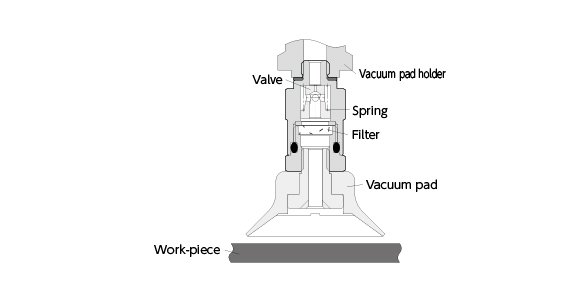

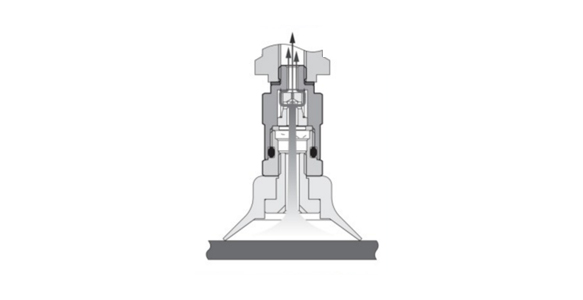

Fall prevention valve operational state

When a work piece is separated from the suction pad, the air flow pushes the valve, closing the pathway.

When the valve operates, a small amount of air is sucked in through the small hole in the center of the valve.

Work suction state

The suction flow of the vacuum lowers when the water adheres to a vacuum pad so that the valve is pushed up by the spring strength, opening a suction path between the valve and the product body.

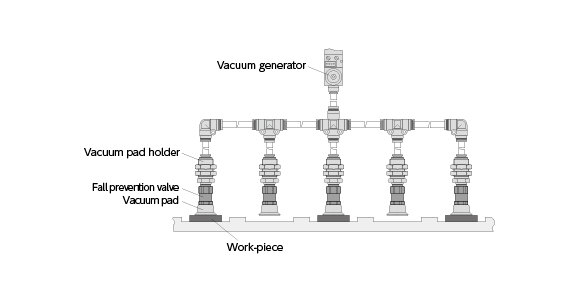

Vacuum Generator

When using a vacuum generator, or when using a vacuum pump for multiple vacuum pads, it is possible to prevent trouble by automatically reducing suction when workpieces are not in contact with the pad frame or a non-critical number of workpieces have separated from pads, or lowering the level of vacuum within the system as a whole, thus stopping operations.

When adopting this system, ensure that the system allows cases where a number of items that would interfere with transport when pads are separated to be deemed unacceptable and that safety measures are employed.

Refer to the catalog for information on specifications for fall prevention and replacement elements other than those above, as well as safety precautions.