XYZ-Axis Manual Stages, Linear Ball Guide

Caution

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part09 CLICK here

Product Description

- XYZ-Axis Manual Stages, Linear Ball Guide type, E-XYZSG series from MISUMI.

- This is an economy item, The price is cheaper than the MISUMI standard product.

- 3 stage sizes are available, 40, 60 and 80 mm.

- The load capacity is 49 N.

- Minimum Reading is 10 μm.

- The material of XYZ-Axis Manual Stages E-XYZSG series are made of D2 Tool Steel with Chemically Nickel Plating surface treatment.

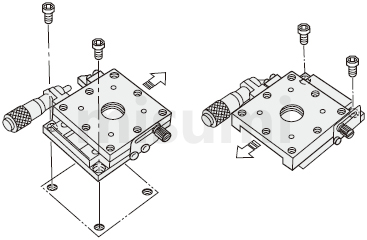

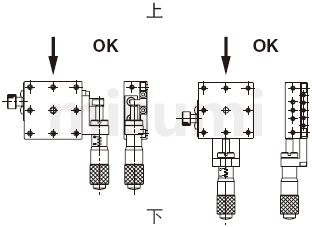

- Can select 4 types of alteration for changing the position of the micrometer knob, Center (A), Side Up (C), Side Down (CU) and Reverse (R).

*A40, A60, A80 are available sizes of the screw hole on sliding table

| Shape |  Material Material |  Surface Treatment Surface Treatment |

| Body | SUS440C | Electroless Nickel Plating |

| Z Support | Aluminum | Clear Anodized |

■Travel Distance

The catalog drawing dimensions are based on a stroke of 0 mm. The distance moved to the left or right from this reference point is the travel distance.

■Load Capacity

Refers to the force that the slide table can withstand when the center of gravity of the workpiece is located at the center of the slide table, measured in N. If the load capacity is exceeded, the slide table may not operate smoothly or may become stuck. When installing the linear motion stage vertically or upside down, the accuracy may be lower than the values indicated in the product catalog. Please be aware.

■Straightness

The maximum deviation from the ideal movement axis (the straight line connecting the start and end points, shown as the red line in the diagram below. The black line represents the actual movement path.) when the slide table moves along its entire stroke. Inspection method: Place the dial indicator on the sliding table, position the pointer against the reference block, move the sliding table through its full stroke, and measure the maximum displacement, which is the straightness.

| Alterations | Changing the position of the micrometer knob | |||

| Spec. | Center | Side Up | Side Down | Reverse |

| Code | A | C | CU | R |

| Part Number | Slide Table Surface (mm) | Travel Distance (mm) X, Y, Z Axes | Load Capacity (N) | Straightness (µm) | Minimum Reading (µm) | Weight (kg) | |

Type Type |  No. No. | ||||||

| E-XYZSG | 40 | 40 × 40 | ±6.5 | 49 | Up to 10 | 10 | 0.78 |

| 50 | 50 × 50 | 1.08 | |||||

| 60 | 60 × 60 | 1.38 | |||||

| 70 | 70 × 70 | 2 | |||||

| 80 | 80 × 80 | ±12.5 | 3 | ||||

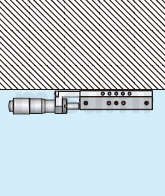

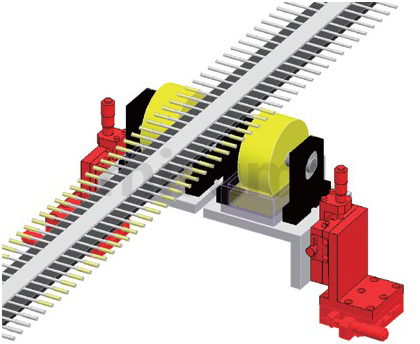

When installing the slide table onto the base, the slide table surface is generally moved for installation. Please refer to the diagram below.

The above image is for installation example demonstration only. Please refer to each product catalog or 3D data for detailed shape and specifications of the slide table.

The above image is for installation example demonstration only. Please refer to each product catalog or 3D data for detailed shape and specifications of the slide table.■ Mounting Orientation

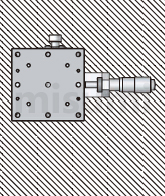

| Diagram |  |  |  |  |

| Installation Orientation | Horizontal | Invert | Side Horizontal | Side Vertical |

| Load Resistant Characteristics | ○ | ○ | △ | △ |

Selectable horizontal, inverted, side horizontal, or side vertical installation. Please pay attention to installations other than the above.

Selectable horizontal, inverted, side horizontal, or side vertical installation. Please pay attention to installations other than the above. Different installation orientations will significantly affect load capacity and accuracy.

Different installation orientations will significantly affect load capacity and accuracy. ○: Same level load resistance.

○: Same level load resistance. △: The approximate standard for horizontal load resistance is about 1/3 of the vertical load resistance. If the product catalog lists the vertical load resistance, it takes precedence.

△: The approximate standard for horizontal load resistance is about 1/3 of the vertical load resistance. If the product catalog lists the vertical load resistance, it takes precedence.■Vertical Use of X-Axis Slide Table

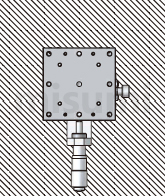

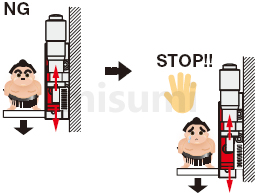

When using the X-axis slide table vertically, please pay attention to the feed direction and avoid aligning it with the direction of gravity.

When using the micrometer knob type stage, please note that the stage is reset by a tension spring. If a force greater than the spring load is applied, the slide table may drop. In such cases, additional processing can be used as a solution.

| Incorrect Usage | Correct Usage |

| (Normally) If a force exceeding the spring's tensile load is applied, the slide table may slip off due to insufficient load capacity. | After selecting the additional processing for changing the micrometer knob position, the stage surface will not drop even when used vertically. |

|  |

Please avoid applying a vertical load that exceeds the load-bearing capacity.

Please avoid applying a vertical load that exceeds the load-bearing capacity.Recommended environment: 10–50°C, 20–70% RH (no condensation)

Accuracy guaranteed environment: 22±5°C, 20–70% RH (no condensation)

■ Guiding Mechanism

This slide table uses a linear ball guide as the guiding mechanism

■ Clamping Mechanism

(1) The clamping mechanism of the slide table is fixed by the friction force generated by tightening screws. Therefore, if the external force applied exceeds the friction force of the clamping mechanism, the slide table will move. Please take appropriate measures during use to prevent the slide table surface from moving. If additional clamping is required, you can choose either disc clamping or opposed clamping.

(2) Holding force refers to the amount of force that keeps the slide table surface from moving while clamped. Since the maximum holding force varies with changes in tightening torque, please ensure a sufficiently large safety factor in your design.

■ Feed Mechanism

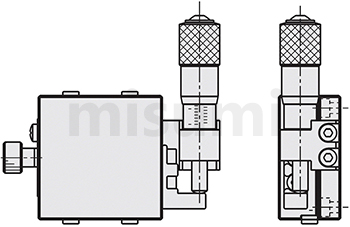

The shape of the stage equipped with a micrometer knob as shown below is generally referred to as the standard type. You can freely choose based on installation space, installation orientation, and operation method. However, due to the construction of the product, there are some models for which the installation position of the micrometer knob cannot be changed. For details, please refer to the "Additional Processing" section at the bottom of each product page.

■ Flatness of the mounting surface

The upper and lower slide tables may deform due to differences in the flatness of their mounting surfaces. Deformation of the slide table may cause gaps, inability to achieve the specified preload resulting in looseness, or excessive preload leading to poor sliding performance. Therefore, it is recommended to keep the flatness of the mounting surface at around 5 micrometers.

When installing the sliding table on the base, the method of moving the sliding table is basically adopted. See the image below.

| Description |  |  |  |  |

| Installation Direction | basic | Ceiling Mount | Side mount | Vertical mounting |

| Load resistance characteristics | ○ | ○ | △ | △ |

Choose from horizontal, inverted, side horizontal or vertical side installation. Caution is required for other installations.

Choose from horizontal, inverted, side horizontal or vertical side installation. Caution is required for other installations.  Load resistance and accuracy vary greatly depending on the mounting posture.

Load resistance and accuracy vary greatly depending on the mounting posture.  ○: Same level of load resistance.

○: Same level of load resistance.  △: Approximately 1/3 of the horizontal load resistance is a rough guideline, and the vertical load resistance listed in the product catalog is recommended.

△: Approximately 1/3 of the horizontal load resistance is a rough guideline, and the vertical load resistance listed in the product catalog is recommended. ■Using the X-axis slide table vertically

When using the X-axis slide table vertically, be careful with the travel direction not in the same direction as gravity.

When using the micrometer handle type slide, the slide is returned by the tension spring. If a force exceeding the spring load is applied, the slide table may fall.

| Incorrect usage | Correct usage |

|  |

Do not apply a load exceeding the load range in the vertical direction.

Do not apply a load exceeding the load range in the vertical direction.| Electronics/home appliance | Automotive | Medical | ||

|  |  | ||

| Smart phone | Semiconductor | Lithium battery | ||

|  |  |

| Economy Electric Slide Table X-Axis | Economy Electric Slide Table XY Axis | Economy Electric Slide Table Z-Axis | ||

|  |  | ||

| Representative Model: C-XMBS420-L-A-2 | Representative Model: C-XYMBS420-L-A-2 | Representative Model: C-ZMBS420-L-A-2 | ||

| Advantages: Low price, fast delivery | Advantages: Low price, fast delivery | Advantages: Low price, fast delivery |