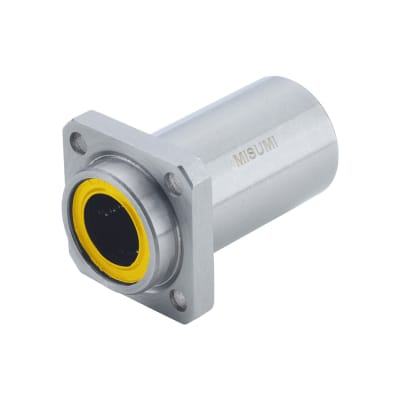

Square Flanged Linear Bushings With Pilot, Medium

Caution

- - This product focuses on price competitiveness, and the unit price is low, but there may be rust, scratches, or scratches on the exterior. For those who place importance on product appearance, we recommend purchasing existing Misumi products rather than economy products. - If domestic stock is insufficient, the minimum order quantity may be temporarily increased. we ask For your understanding. - Due to the retainer color change (existing: black, changed: yellow), the color may differ from the representative image, and colors may be mixed and shipped.

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part02 CLICK here

Product Description

Square Flanged Linear Bushings are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Inner Diameter Minimum/Maximum (mm.) : 6 and 30

● Overall Length Minimum/Maximum (mm.) : 29 and 90

● Operating Temperature (℃) : -20 to 80

● Material

Housing and Ball - SUJ2 Equivalent

Retainer - Resin

[Application]

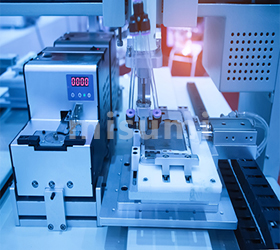

Square Flanged Linear Bushings are commonly used in various applications in factory automation systems

Economy Square Flanged Linear Bushing with Pilot

- Robust square flange for stable and secure installation.

- Available in various sizes

- Durable construction with SUJ2 equivalent material.

- Suitable for varied industrial applications.

- Excellent interchangeability with different shafts.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product Overview of Linear Bushings

The embedded flanged linear bearing does not extend to the opposite side of the mounting surface, so there is sufficient space on the opposite side of the mounting surface.

Product Features of Linear Bushings

Through the rolling of steel ball, high-efficiency movement with low friction resistance can be realized.

Linear Bushings Feature 1: Effective utilization of space. The combination of the guide shaft and the linear bearing enables effective use of space, suitable for small mechanism designs.

Linear Bushings Feature 2: Good interchangeability. Linear bearings have good interchangeability because they can be used with shafts randomly.

Linear Bushings Feature 3: Overall length is about 1.5 times and allowable moment about 4.3 times that of the single liner type.

Linear Bushings Feature 4: Appropriate specifications can be selected according to the conditions of use.

Linear Bushings Feature 5: More cost effective than the linear guide.

Dimensional Drawing of Linear Bushings

Specifications Overview of Linear Bushings

| Housing | Ball | Retainer | Operating Environment Temperature |  Accessories Accessories | ||

Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment |  Material Material |  Material Material | ||

| Equivalent to SUJ2 | 58HRC~ | Electroless Nickel Plating | Equivalent to SUJ2 | Resin | -20 to 80℃ | Seal packing Material MaterialNitrile Rubber (-20 to 120℃) |

Usage Method of Linear Bushings

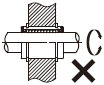

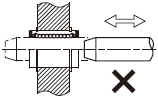

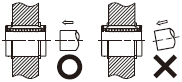

| Product Drawings of Linear Bushings | Instructions for use Linear Bushings | ||||||||

| When the linear bearing is under heavy load (unbalanced load), one piece of single liner type is not applicable. It is recommended to use one piece of double liner type or multiple pieces of single liner type. | ||||||||

| Linear Bushings is not suitable for rotating motion in structure. If you rotate forcibly, it may cause damage to the product. Please pay attention during use. | ||||||||

| Linear bearing is not suitable for repeated plugging and unplugging. | ||||||||

| When inserting the guide shaft into the linear bearing, please align the center and insert it slowly, otherwise the steel ball will fall off or the retainer will be deformed. | ||||||||

Precautions of Linear Bushings

① Before use, please apply grease to the ball row inside the linear bearing, and then replenish it in due course. Grease forms an oil film on the surfaces of steel ball and rolling surface (guide shaft·bushing) of linear bearing, which effectively reduces friction and prevents sintering. Grease reduction and aging will greatly affect the life of linear bearing.

② Recommended grease: lithium soap grease.

for details. ③ Recommended grease filling interval: Usually every 6 months.

④When the moving distance is long, it is recommended to move once every three months or when the moving distance exceeds 1000km within the time limit, the 1000km shall prevail.

⑤ When the linear bearing is subjected to large moment load (eccentric load), one piece of single liner type is not applicable, so it is recommended to use one piece of double liner type or multiple pieces of single liner type.

■ Linear Bushings Dust prevention measures:

If dust or foreign matter enters the inside of the linear bearing, it may damage the circulation of steel balls, resulting in unexpected failures. When used in harsh environment, please install dust cover and protection cover, etc.

■ MISUMI linear bearing is recommended to be combined with guide shaft with quenching g6 tolerance.

■ MISUMI linear bearing is recommended to be installed on the holder with H7 tolerance. The linear bearing is in clearance fit with the holder.

Related Documents of Linear Bushings

Usage Method of Linear Bushings.

Usage Method of Linear Bushings.For anti-rust performance and maintenance of metal materials and their surface treatment, please refer to

Anti-rust Performance.

Anti-rust Performance.Application Industries of Linear Bushings

| Electronic & Electrical Appliances | Automotive | Lithium battery | ||

|  |  | ||

| LCD | Smart phone | Semiconductor | ||

|  |  |

Related Products of Linear Bushings

| Housing | Ball | Retainer | Operating Environment Temperature |  Accessories Accessories | ||

Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment |  Material Material |  Material Material | ||

| Equivalent to SUJ2 | 58HRC~ | Electroless Nickel Plating | Equivalent to SUJ2 | Resin | -20 to 80℃ | Seal packing Material MaterialNitrile Rubber (-20 to 120℃) |

■Dimension Specification Table

| Part Number | D | L | ℓ | H | T | d | d1 | t | P.C.D. | W | Lateral misalignment | Number of ball rows | * Perpendicularity | Basic Rated Load | Allowable Static Moment (N·m) | Weight (g) | ||||

| dr | Tolerance | Tolerance | Tolerance | C (Dynamic) N | Co (Static) N | Square Flanged | ||||||||||||||

| 6 | 0 -0.01 | 12 | 0 -0.021 | 29 | ±0.3 | 5 | 28 | 5 | 3.5 | 6 | 3.1 | 20 | 22 | 0.03 | 4 | 0.04 | 226 | 310 | 1.42 | 21 |

| 8 | 15 | 37 | 32 | 24 | 25 | 310 | 452 | 2.12 | 39 | |||||||||||

| 10 | 19 | 0 -0.023 | 47 | 6 | 40 | 6 | 4.5 | 7.5 | 4.1 | 29 | 30 | 508 | 718 | 4.37 | 65 | |||||

| 12 | 21 | 42 | 32 | 32 | 634 | 814 | 6.2 | 69 | ||||||||||||

| 16 | 28 | 56 | 48 | 38 | 37 | 5 | 1164 | 1448 | 13.1 | 132 | ||||||||||

| 20 | 0 -0.012 | 32 | 0 -0.028 | 65 | 8 | 54 | 8 | 5.5 | 9 | 5.1 | 43 | 42 | 0.038 | 0.04 | 1554 | 2068 | 18.3 | 197 | ||

| 25 | 40 | 83 | 62 | 51 | 50 | 6 | 1725 | 3068 | 25.3 | 442 | ||||||||||

| 30 | 45 | 90 | 10 | 74 | 10 | 6.6 | 11 | 6.1 | 60 | 58 | 2440 | 3974 | 42.7 | 482 | ||||||

* mark shows the verticality between Part D and the flange mounting surface.

* mark shows the verticality between Part D and the flange mounting surface. For information on the flanged height adjusting ring, please refer to the

For information on the flanged height adjusting ring, please refer to the  Adjusting Ring.

Adjusting Ring.