Clamping Screws Ball Type

Caution

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part09 CLICK here

Product Description

- MISUMI offers the C-RSM series of Ball Tips Clamping Screws.

- The main body of the clamping ball screw is made of an equivalent material to 40Cr.

- The ball of the clamping screw is made of SUS440C equivalent.

- The screws are available in five sizes: M3, M4, M5, M6, or M8.

- The thread precision of this product has been verified using commercially available nuts equivalent to GB 6G.

- The front end of the ball is highly hardened, making it resistant to wear. It can be used to clamp the workpiece and adjust its angle.

Economy Ball Tip Clamping Screw

- Material: Screw body made of 40Cr equivalent steel, ball made of SUS440C stainless steel.

- Design: Ball-tipped design for versatile clamping and adjustment.

- Size Range: Available in multiple sizes

- Thread Precision: Meets GB 6G standard for accurate fit.

- Hardness: Ball tip hardened to 50-55 HRC for durability.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Clamping Screws Product Overview

Clamping Screws Product Feature

Feature 2: The angle of the workpiece can be adjusted by adjusting the height of the screw.

Feature 3: The front end ball head of the Economy series Clamping Screws can be rotated.

Feature 4: The hardness of the front end ball head is 50 to 55 HRC, so the workpiece can be repeatedly installed and positioned.

Feature 5: All models are available in stock, allowing same-day shipment.

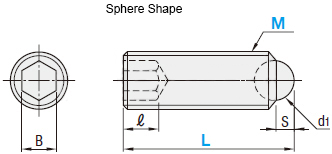

Clamping Screws Dimensional Drawing

The thread precision of this product has been judged qualified through commercially available nuts equivalent to GB 6G.

The thread precision of this product has been judged qualified through commercially available nuts equivalent to GB 6G.Clamping Screws Specifications Overview

| Type | Body | Sphere Shape | M | L Selection | |||

| Sphere Shape |  Equivalent material Equivalent material |  Hardness Hardness |  Surface Treatment Surface Treatment |  Material Material |  Hardness Hardness | ||

| C-RSM | Equivalent to 40Cr | 48HRC to | Ferroferric Oxide Protective Film | SUS440C | 50 to 55HRC | M3~M8 | 5.2~25.8 |

If there are requirements for rust prevention, give priority to products made of stainless steel SUS304. Please refer to the rust prevention method.

If there are requirements for rust prevention, give priority to products made of stainless steel SUS304. Please refer to the rust prevention method.Clamping Screws Usage Method

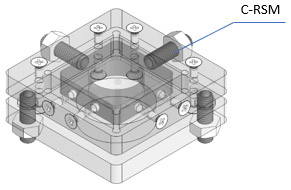

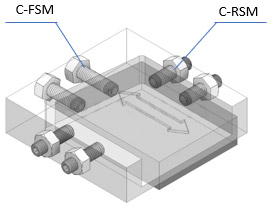

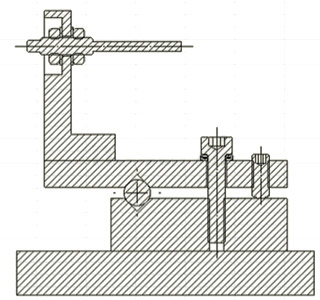

| Product Drawings | Intended Use |

| Adjust the position movement of the workpiece by adjusting the direction of the Clamping Screws. |

| Realize the function of guiding and positioning the workpiece through the Clamping Screws. |

Clamping Screws Example of Use

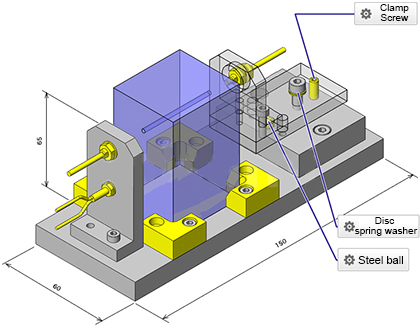

Angle adjustment mechanism using Clamping Screws and steel balls

Mechanism function:

Put the resin case in the inspection position, and check whether the resin case hole is normal through a photoelectric sensor.

The function of the Clamping Screws:

Through the change of the up and down position of the clamping screw, it plays the role of micro-adjusting the emission angle of the photoelectric sensor.

Clamping Screws Related Industries

| Electronic & Electrical Appliances | Smart phone | Medical | ||

|  |  | ||

| Robotics | Semiconductor | Lithium battery | ||

|  |  |

Clamping Screws Precautions

② The front end ball head of the Economy series Clamping Screws can be rotated.

③ The corner seat type hemisphere is sometimes spherical instead of flat after rotating. Use tape and magnet when reversed to restore hemisphere rotation. In addition, when you don't want to reverse, please use turning prevention type.

Clamping Screws Related Products

| Adjusting bolt Hex socket on head Knurled knob type | Metal Washers Standard Grade/Precision Grade Custom Size Type | Axle Pin Bolt | ||

|  |  | ||

| Typical model: AJKTN10-80 | Typical model: FWASB-D15.5-V5.5-T2.6 | Typical model: LMU6 | ||

| Advantages: Positioning by manual adjustment, optional length | Advantages: Matching screws, high precision, multiple types | Advantages: Accurate positioning, high shaft precision |