(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน มิถุนายน 2567 | Notice holiday in June 2024 > คลิก

Air Tube/Nylon Tube(I.D. [Distinction]:~20)

Additionally, we offer tubes capable of supporting various fluids such as water, chemicals, and general hydraulic oil. Complementary products like tube cutters and replacement blades are also available. For top-quality products, we highly recommend trusted brands such as MISUMI, SMC, PISCO, and CHIYODA.

Take advantage of the convenience of FREE SHIPPING and NO MINIMUM ORDER on Air tubes and related products. Should you have any doubts or require assistance in choosing the right product, our experts are readily available to provide advice and guidance.

Configure

Specification/Dimensions

-

Outer Dia. D(Ø)

-

Inner Dia. d(Ø)

- 0.46

- 0.7

- 0.8

- 0.86

- 0.9

- 1

- 1.19

- 1.2

- 1.5

- 1.59

- 1.6

- 1.8

- 1.93

- 2

- 2.1

- 2.16

- 2.25

- 2.36

- 2.4

- 2.42

- 2.5

- 2.6

- 2.7

- 2.9

- 2.99

- 3

- 3.17

- 3.21

- 3.48

- 3.5

- 3.7

- 3.95

- 3.96

- 4

- 4.02

- 4.15

- 4.35

- 4.5

- 4.57

- 4.72

- 4.76

- 4.81

- 5

- 5.28

- 5.5

- 5.7

- 5.9

- 5.99

- 6

- 6.3

- 6.33

- 6.35

- 6.4

- 6.5

- 6.8

- 6.99

- 7

- 7.5

- 8

- 8.3

- 8.4

- 8.5

- 9

- 9.5

- 9.52

- 9.56

- 9.8

- 10

- 10.7

- 11

- 12

- 12.5

- 12.7

- 12.8

- 13

- 14

- 15.88

- 15.9

- 16

- 18

- 20

- 22

- 22.2

- 22.22

- 25.4

-

Material

- Urethane

- Nylon

- Fluororesin

- Polyamide

- Fluororubber

- Silicon Rubber

- Polyolefin Resin

- Others

- PVC

- Nylon/Fluoropolymer

-

Applicable Fluid

- Water

- Air

- Chemical

- General Hydraulic Oil

- Thermal Media Oil

- Vacuum

-

Color

- Black

- White

- Milky White

- Transparent (including non-white colors)

- Red

- Blue

- Yellow

- Green

- Orange

- Ocher

- Gray

- Multi Color

- Pink

- Others

- Brown

- Purple

- Silver

-

Type

-

Operating Environment

- Standard

- Clean Environment

- Corrosion Resistant

- Antistatic

- Sputtering Resistant

- Mold Cooling

- Water Resistance

- Pressure Resistance

- Vacuum

- Heat Resistance

- Abrasion Resistance

- Oil Resistance

- low temperature resistance

- Weather Resistance

- Ozone Resistance

- Sulfur Resistance

- Chemical Resistance

-

O.D. [Distinction]

-

Cutting Service Usage

- Yes

- No

-

Material: Nylon

-

I.D. [Distinction]

-

Material, Fluororesin

-

Material, Urethane

-

Number of Core(Core)

-

O.D. (2nd Core)

-

O.D. (3rd Core)

-

O.D. (4th Core)

-

O.D. (5th Core)

-

I.D. (2nd Core)

-

I.D. (3rd Core)

-

I.D. (4th Core)

-

I.D. (5th Core)

-

Types of Related components

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

- 6 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

Until 31/03/2025Fluoropolymer Tubing (FEP) TH/TIH Series

SMC

A fluoropolymer tubing with superior durability in chemical environments.

[Features]

· Compatible with Japan's Food Sanitation Law.

· Operating temperature: 200°C (varies depending on the conditions).

· RoHS compliant.

· Maximum operating pressure 2.3 MPa or less (at 20°C) (varies by size).

· Complies with the FDA (Food and Drug Administration) §177-1550 dissolution test.From: ฿ 14,196.70 Special Price Days to Ship: 55 Day(s)

55 Day(s)

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

Until 31/03/2025Fluoropolymer Tubing (PFA) Metric Size, TLM Series

SMC

Superior heat resistance: fluoropolymer tubing (PFA) metric size, TLM series.

[Features]

· Uses highly chemical-resistant fluoropolymer.

[Applications]

· Used in the manufacture of solar cells, liquid crystals, hard disk drives, and in the healthcare and food industries.From: ฿ 11,798.00 Special Price Days to Ship: 55 Day(s)

55 Day(s)

-

You can add up to 6 items per a category to the compare list.

Fluoropolymer Tubing (PFA) Inch Size, TILM Series

SMC

Fluoropolymer tubing (PFA) with superior heat resistance, inch size, TILM series.

[Features]

· Uses highly chemical-resistant fluoropolymer.

[Applications]

· Used in manufacturing of solar cells, liquid crystals, hard disk drives, and in the health care and food industries.From: ฿ 2,748.05 Days to Ship: 55 Day(s)

55 Day(s)

-

You can add up to 6 items per a category to the compare list.

Fluoropolymer Tube TA, Clean, Heat Resistant, Cold Resistant, Chemical Resistant

NITTA

[Features]

・ Uses PFA (tetrafluoroethylene / perfluoroalkyl vinyl ether copolymer) resin with excellent chemical resistance

・ Manufactured in a cleanroom, the tube terminal is sealed with a cap, and shipped in heat-sealed packaging

・ It has excellent cleaning properties and reduces the adhesion of chemicals

・ A tube that does not change over time and has excellent weather resistance

・ It can be used even in an environment such as an ozone atmosphere

・ Can also be used for the clean fitting "Chemfit CSE Series"

・ Compliant with Ministry of Health, Labour and Welfare of Japan Notification No. 201 (2006) and Ministry of Health, Labour and Welfare Notification No. 370 (1959)From: ฿ 100.00 Days to Ship: Quote

Quote

-

You can add up to 6 items per a category to the compare list.

Fluorine Resin Tube, Clean, Heat Resistant, Cold Resistant, and Chemical Resistant, TP

NITTA

The fluorine resin tube clean TP is a tube of FEP (tetrafluoride ethylene-hexafluoride propylene polymer) resin with superior chemical resistance, providing excellent washability, low levels of adhesion of chemical solutions, etc., and excellent weather resistance.

[Features]

· Uses FEP (tetrafluoride ethylene-hexafluoride propylene copolymer) resin with excellent chemical resistance.

· Manufactured in a clean room. Tube ends are capped and sealed. Shipped in heat-sealed packaging.

· Cleaning performance is excellent, and adhesion of chemical solutions, etc. is very low.

· Can be used with the "Chemifit C1 series" clean PushOne fitting .

· This is a tube with small secular change and excellent weather resistance.

· Can be used in an ozone atmosphere, etc.

· Health, Labor and Welfare Ministry Notification No. 201 (2006From: ฿ 100.00 Days to Ship: Quote

Quote

-

You can add up to 6 items per a category to the compare list.

TOMBO No. 9003-PFA HG NAFLON PFA-HG Tube

NICHIAS

Fluoropolymer (PFA-HG) tube. The possibility of the inner surface of the PFA tube being smoothed, makes it ideal for use in a semiconductor and liquid crystal industries.

[Features]

· Has smooth (Rt = 0.2 μm) tube inner surface.

· Reduced retention of particles and chemical liquids.

· Improved transparency.

· Improved insulating strength.

· Reduction of eluted fluoride ions.

· Improved stress crack resistance under stress environments (for example: hyperhydrated sulfuric acid, fuming sulfuric acid).From: ฿ 100.00 Days to Ship: Quote

Quote

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Outer Dia. D(Ø) |

| Inner Dia. d(Ø) |

| Material |

| Applicable Fluid |

| Color |

| Type |

| Operating Environment |

| O.D. [Distinction] |

| Cutting Service Usage |

| Material: Nylon |

| I.D. [Distinction] |

| Material, Fluororesin |

| Material, Urethane |

| Number of Core(Core) |

| O.D. (2nd Core) |

| O.D. (3rd Core) |

| O.D. (4th Core) |

| O.D. (5th Core) |

| I.D. (2nd Core) |

| I.D. (3rd Core) |

| I.D. (4th Core) |

| I.D. (5th Core) |

| Types of Related components |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | SMC | SMC | SMC | NITTA | NITTA | NICHIAS |

| Product Series | Fluoropolymer Tube TA, Clean, Heat Resistant, Cold Resistant, Chemical Resistant | Fluorine Resin Tube, Clean, Heat Resistant, Cold Resistant, and Chemical Resistant, TP | ||||

| From | ฿ 14,196.70 Special Price On Sale Until 31/03/2025 | ฿ 11,798.00 Special Price On Sale Until 31/03/2025 | ฿ 2,748.05 | ฿ 100.00 | ฿ 100.00 | ฿ 100.00 |

| Days to Ship | 55 Day(s) | 55 Day(s) | 55 Day(s) | Quote | Quote | Quote |

| Outer Dia. D(Ø) | - | 19 | - | 19.1 ~ 24 | 21 | 19.05 |

| Inner Dia. d(Ø) | - | 16 | - | 15.9 ~ 20 | 18 | 15.88 |

| Material | Fluororesin | Fluororesin | Fluororesin | Fluororesin | Fluororesin | Fluororesin |

| Applicable Fluid | Water / Air | Water / Air / Chemical | Water / Air / Chemical | Water / Air | Water / Air | Water / Air / Chemical |

| Color | Black / Transparent (including non-white colors) | Black / Transparent (including non-white colors) | Black / Transparent (including non-white colors) | Transparent (including non-white colors) | Transparent (including non-white colors) | Transparent (including non-white colors) |

| Type | Straight | Straight | Straight | Straight | Straight | Straight |

| Operating Environment | Standard / Heat Resistance / Chemical Resistance | Standard / Heat Resistance / Chemical Resistance | Standard / Heat Resistance / Chemical Resistance | Standard | Standard | Standard / Clean Environment / Antistatic / Heat Resistance / Weather Resistance / Chemical Resistance |

| O.D. [Distinction] | ~20 | ~20 | ~20 | ~20 ~ ~30 | ~30 | ~20 |

| Cutting Service Usage | No | No | No | No | No | No |

| Material: Nylon | - | - | - | - | - | - |

| I.D. [Distinction] | ~20 | ~20 | ~20 | ~20 | ~20 | ~20 |

| Material, Fluororesin | Standard Fluororesin | Standard Fluororesin | Standard Fluororesin | Others | Others | Standard Fluororesin |

| Material, Urethane | - | - | - | - | - | - |

| Number of Core(Core) | - | 1 | 1 | - | - | 1 |

| O.D. (2nd Core) | - | - | - | - | - | - |

| O.D. (3rd Core) | - | - | - | - | - | - |

| O.D. (4th Core) | - | - | - | - | - | - |

| O.D. (5th Core) | - | - | - | - | - | - |

| I.D. (2nd Core) | - | - | - | - | - | - |

| I.D. (3rd Core) | - | - | - | - | - | - |

| I.D. (4th Core) | - | - | - | - | - | - |

| I.D. (5th Core) | - | - | - | - | - | - |

| Types of Related components | - | - | - | - | - | - |

Loading...

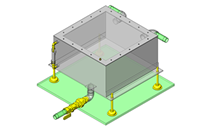

Application example related to this category

Related Categories to Air Tube/Nylon Tube

-

- Cylinders, Rotary Actuators

- Cylinder Connecting Components

- Filters, Regulators, Lubricators

- Solenoid Valves

- Electromagnetic Valves

- Pneumatic Pipe Fittings

- Speed Controllers

- Silencers

- Manual-Type Valves, Mechanical-Type Valves

- Air Tube/Nylon Tube

- Fluororesin Products for Chemicals

- Pressure, Flow Rate Sensors

- Dryers

- Compressors, Blowers

- Other Pneumatic Devices

-

FAQ Air Tube and Nylon Tube

-

- Question: Will there any problem if silicone oil flown through the soft nylon tubes?

- Answer: No problem.

- Question: Can I use the water-resistant Poly urethane spiral tubes with oil?

- Answer: It cannot be used with oil.

- Question: What is the accuracy of inner diameter of the soft Polyurethane tubes?

- Answer: There are no standard for the accuracy of inner diameter.

This is because it is used for inserting to the joint. - Question: What are the features of vacuum tubes?

- Answer: They are crush-resistant and be able to maintain a certain amount of hose inner diameter even in the vacuum conditions.

- Question: The material of the Polyolefin tubes is displayed as “Polyolefin-based resin”, can you provide more details about the material name?

- Answer: It is a special polyolefin-based elastomer.

- Question: Do you offer Air Tubes with hardness degree of Shore A60?

- Answer: Yes.

Air Tubes/Silicon Type have hardness degree of Shore A65. - Answer: 1. Flexibility: Polyurethane tubes are highly flexible and can bend without kinking or losing their shape.

2. Durability: They are resistant to abrasion, impact, and tearing, making them durable.

3. Chemical Resistance: Polyurethane tubes can resist a wide range of chemicals, oils, fuels, solvents, and gases.

4. High Strength: Despite their flexibility, they have high tensile, allowing them to handle high pressure.

5. Temperature Resistance: They can withstand a wide temperature range, from low to moderate temperatures.

6. UV Resistance: Many polyurethane tubes have good resistance to ultraviolet (UV) radiation. - Question: What are the applications of polyurethane hoses?

- Answer: Polyurethane tubes are used in a wide range of applications across various industries. They find particular use in industries such as the automotive industry, robotics and automation, industrial machinery, and the food and beverage industry. In pneumatic systems, they are utilized to connect pneumatic equipment, including air fittings, air guns, directional control valves, and more. Additionally, polyurethane tubes serve multiple purposes, such as fluid transfer, vacuum systems, agricultural equipment, medical equipment, HVAC systems, and more.

- Question: What are the benefits of using polyurethane rubber hoses?

- Answer: The benefits of using polyurethane rubber hoses include:

1. Flexibility: Polyurethane hoses are highly flexible, making them easy to handle, install, and maneuver in tight spaces.

2. Durability: They are resistant to abrasion, impact, and tearing, resulting in longer service life and reduced maintenance costs.

3. Chemical Resistance: Polyurethane hoses exhibit good resistance to a wide range of chemicals, including oils, fuels, solvents, and many gases.

4. High Strength: Despite their flexibility, they have high tensile strength and can withstand high pressures without deformation.

5. Lightweight: Polyurethane hoses are lightweight, which improves handling and reduces the overall weight of the system.

6. Temperature Resistance: They can withstand a wide temperature range, enabling their use in both high-temperature and low-temperature applications.

7. UV Resistance: Many polyurethane hoses have good resistance to ultraviolet (UV) radiation, making them suitable for outdoor applications.

8. Versatility: Polyurethane hoses can be used in various industries and applications, including pneumatic systems, fluid transfer, vacuum systems, and more.

9. Reduced Noise: They have excellent noise-damping properties, reducing the noise level in pneumatic systems and improving workplace comfort. - Question: What are the difference Polyurethane vs. traditional rubber hoses?

- Answer: 1. Material: Polyurethane hoses are made from thermoplastic polyurethane (TPU), while traditional rubber hoses are made from natural or synthetic rubber.

2. Flexibility: Polyurethane hoses are more flexible and can be bent without kinking, while traditional rubber hoses are less flexible.

3. Abrasion Resistance: Polyurethane hoses have excellent abrasion resistance, while traditional rubber hoses are generally less resistant to abrasion.

4. Chemical Compatibility: Polyurethane hoses have better chemical resistance, while traditional rubber hoses may have limitations in certain chemical applications.

5. Temperature Range: Polyurethane hoses have a wider temperature range, while traditional rubber hoses may have limitations at extreme temperatures.

6. Weight: Polyurethane hoses are lighter in weight compared to traditional rubber hoses.

7. Cost: traditional rubber hoses are typically more cost-effective than polyurethane hoses.

Remember that specific properties can vary based on manufacturer and application, so it's always a good idea to consult product specifications for accurate information. - Question: How to choose the right polyurethane hose for your application?

- Answer: Here are some factors to consider when choosing the right polyurethane tube for your application:

1. Pressure rating: The pressure rating of the tube must be higher than the pressure of the fluid or gas that will be flowing through it.

2. Temperature range: The tube must be able to withstand the temperature of the fluid or gas that will be flowing through it.

3. Chemical resistance: The tube must be resistant to the chemicals that will be flowing through it.

4. Flexibility: The tube must be flexible enough to accommodate the bends and curves in your application.

5. Tensile strength: The tube must be strong enough to withstand the forces that will be exerted on it.

6. Weight: The weight of the tube is important if you need to move it around or install it in a difficult location.

7. Cost: The cost of the tube is an important factor to consider, especially if you need a large quantity of it.

-

- Question: What is the white color of the water-resistant Polyurethane tubes? Pure white or translucent?

- Answer: It is translucent.

-

- Question: Does the flame retardant of Fluororesin Tubes certified with UL Standard?

- Answer: They have not been certified by UL Standard.

-

- Question: Is it possible to cut the Multi spiral tubes?

- Answer: Yes, it can be cut but product warranty will be voided after cut.

- Question: Can I cut the Fluororubber plate with 2mm thickness by cutter?

- Answer: For 2mm thickness plate, it can be cut with scissors or cutter.

- Question: Does lining process applicable for Vulkollan and Abrasion resistant type Urethane rubber?

- Answer: Vulkollan rubber is not available for lining process.

Abrasion resistant type Urethane is available for lining process. - Question: Please describe how to cut Urethane Silicone and Felts material.

- Answer: They can be cut by cutter or scissors.

However, it may be difficult depending on the hardness and thickness.

In that case, we recommend using a cutting machine. - Question: Do you offer an adhesive for Rubber?

- Answer: Yes, please check on Moment Adhesives for Rubber for Silicon

These products consist of 2 types: BONDR and BONDS. Please select it based on your rubber material. - Question: Do you offer an adhesive for Urethane?

- Answer: Yes, please check on Adhesives for Urethane(BOND-U)

- Question: What are the properties of Polyurethane tube?

How can we improve?

How can we improve?