(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน พฤษภาคม 2567 | Notice holiday in May 2024 > คลิก

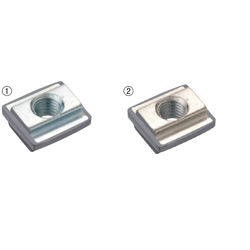

Nuts(Function:With Stoppers)

Configure

Specification/Dimensions

-

Series

- MISUMI 3 Series

- MISUMI 5 Series

- MISUMI 6 Series

- MISUMI 8 Series

- MISUMI 8-45 Series

- SUS SF20 Series (6mm Groove width Type)

- SUS SF30 Series (8mm Groove width Type)

- SUS SF40 and 45 Series (10mm Groove width Type)

- LECOFRAME 25 Series (For Light/Medium Structures)

- LECOFRAME 40 Series (For Medium/Heavy Structures)

- NIC Autotec M4 Series

- NIC Autotec M6 Series

- NIC Autotec M8 Series

- NIC Autotec H10 Series

- NIC Autotec Conveyor Frame

- IMAO (I-Frame) 20 Series

- IMAO (I-Frame) 30 Series

- IMAO (I-Frame) 40 Series

- IMAO (item) Line 5

- IMAO (item) Line 6

- IMAO (item) Line 8

- MISUMI, European Standard, Groove Width: 6 mm, Dedicated for Aluminum

- MISUMI, European Standard, Groove Width: 8 mm, Dedicated for Aluminum

- MISUMI, European Standard, Groove Width: 10 mm, Dedicated for Aluminum

-

Nominal of Thread M(mm)

- M3

- M4

- M5

- M6

- M8

- M7

- M8.5

- M10

-

Material

- Steel

- Stainless Steel

- Plastic

- Aluminum

- Copper

- Zinc Alloy

-

Function

-

Standard

Standard -

Economy

Economy -

Nuts and Stoppers Set

Nuts and Stoppers Set -

With Leaf Springs

With Leaf Springs -

With Ball Springs

With Ball Springs -

With Stoppers

With Stoppers -

With Locks

With Locks -

Conductive

Conductive -

Eccentricity

Eccentricity -

Short, Rotating

Short, Rotating -

Plastic Stoppers

Plastic Stoppers -

Metal Stoppers

Metal Stoppers -

With galling prevented

With galling prevented

-

-

Lock

- Provided

- Not Provided

|

Nut Type

|

|

|---|---|

Brand |

|

Filter By |

|

| CAD |

|

| Days to Ship |

|

- 6 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

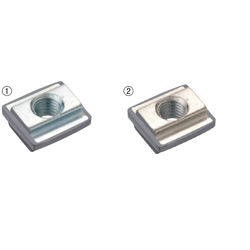

Stopper Integrated Nuts For 8 Series (Slot Width 10mm) Aluminum Frames

MISUMI

This product integrates a pre-assembly insertion nut and a pre-assembly insertion stopper. You can also purchase each part individually.From: ฿ 15.46 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025

Until 31/03/2025

Until 31/03/20256 Series/Pre-Assembly Insertion Nuts (Stopper Integrated)

MISUMI

Product that integrates a pre-assembly insertion nut and a pre-assembly insertion stopper. You can also purchase each part individually.From: ฿ 13.71 Special Price Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025

Until 31/03/2025

Until 31/03/20255 Series/Stopper Integrated Pre-Assembly Insertion Nuts

MISUMI

·Product that integrates a pre-assembly insertion nut and a pre-assembly insertion stopper. You can also purchase each part individually.From: ฿ 13.13 Special Price Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

Until 31/03/2025MISUMI

This product integrates a pre-assembly insertion nut and a pre-assembly insertion stopper. You can also purchase each part individually.From: ฿ 15.46 Special Price Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

Until 31/03/2025Strengthening Nut (Slip Prevention Combined Unit)【1-50 Pieces Per Package】

NIC AUTOTEC

·Structural element of factory automation equipment. [Nut Type]Pre-assembly insertion nut.From: ฿ 50.79 Special Price Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

YAMATO CO LTD

● Nut for aluminum extrusion. Right one has anti-slip processing (YHN type)From: ฿ 10.00 Days to Ship: 1 Day(s)

1 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Nut Type |

| Series |

| Nominal of Thread M(mm) |

| Material |

| Function |

| Lock |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI | MISUMI | MISUMI | NIC AUTOTEC | YAMATO CO LTD |

| Product Series | Stopper Integrated Nuts For 8 Series (Slot Width 10mm) Aluminum Frames | Strengthening Nut (Slip Prevention Combined Unit)【1-50 Pieces Per Package】 | ||||

| CAD |

|

|

|

|

| |

| From | ฿ 15.46 | ฿ 13.71 Special Price On Sale Until 31/03/2025 | ฿ 13.13 Special Price On Sale Until 31/03/2025 | ฿ 15.46 Special Price On Sale Until 31/03/2025 | ฿ 50.79 Special Price On Sale Until 31/03/2025 | ฿ 10.00 |

| Days to Ship | Same day | Same day | Same day | Same day | Same day | 1 Day(s) |

| Nut Type | Pre-Assembly Insertion Nuts | Pre-Assembly Insertion Nuts | Pre-Assembly Insertion Nuts | Pre-Assembly Insertion Nuts | Pre-Assembly Insertion Nuts | Pre-Assembly Insertion Nuts |

| Series | MISUMI 8 Series | MISUMI 6 Series | MISUMI 5 Series | MISUMI 8-45 Series | NIC Autotec M4 Series / NIC Autotec M6 Series / NIC Autotec M8 Series | - |

| Nominal of Thread M(mm) | M3 / M4 / M5 / M6 / M8 | M3 / M4 / M5 / M6 | M3 / M4 / M5 | M4 / M5 / M6 / M8 | M4 / M6 / M8 | M4 / M6 / M8 |

| Material | Steel / Stainless Steel | Steel / Stainless Steel | Steel / Stainless Steel | Steel / Stainless Steel | Steel | Steel |

| Function | With Stoppers | With Stoppers | With Stoppers | With Stoppers | With Stoppers | With Stoppers |

| Lock | Not Provided | Not Provided | Not Provided | Not Provided | Not Provided | Not Provided |

Loading...

Related Categories to Nuts

-

- Aluminum Frames

- Special AEX

- AEX Units

- Brackets and Joint Parts

- Nuts

- Bolts

- Frame Caps

- Slot Covers

- Handles

- Hinges

- Catches and Locks

- Casters

- Foot Bases for Aluminum Extrusions

- Adjuster Pads

- Panel Mounts

- Curtains, Sheets

- Door Sliders

- Conveyor Parts

- Clamps, Holders, Hooks

- Jigs, Maintenace Parts

- Concealed(invisible) joint parts/frame with joints

- Accessories for aluminum alloy profiles

- Transparent Plastic Covers

- Perforated Metals, Fences, Nets, Panels

-

FAQ Nuts (for Aluminum extrusions)

-

- Question: Can JIS standard hexagon nuts and square nuts be used for Aluminum extrusions?

- Answer: No.

A special nut that fits into the groove of the Aluminum extrusion shall be used to secure a large area of buckling pressure and prevents buckling of the Aluminum extrusion. - Question: Can nuts and brackets be used in common with any type of Aluminum extrusion?

- Answer: It can be used within the same series.

Since the groove shape is the same, accessories can be used in common. - Question: Is it possible to attach nuts and bolts made of stainless steel as the attachment for alteration code of black bracket as "with applicable bolts and nuts set"

(e.g.:HBLFSNB6-SST, HBLFSNB6-SSU, HBLFSNB6-SSP , etc.) - Answer: No, because there are no black stainless-steel bolts that correspond to the black bracket, so it cannot be attachment for alteration "with applicable bolts and nuts set".

- Question: Is there any product to prevent the fastening part from loosening?

- Answer: Yes.

• Screws with Captured Spring Washer Bulk Packages (500 pcs. per Package) (HCBST)

• Nut with Loosen Prevention Function (HNTTV□/HNTTZ□-series)

□ is Aluminum extrusion No. - Question: What is the difference between the 8-series and 8-45-series when selecting nuts for Aluminum extrusions?

- Answer: The Model No. used for the Pre-Assembly Insertion Stoppers and Stopper Integrated Nuts are different between the 8-series and 8-45-series. Other nuts can be used in common.

• 8-series:Pre-Assembly Insertion Stoppers HNST8, Stopper Integrated Nuts HNTE8, stainless steel material is model SHNTE8

• 8-45-series:HNST8-45, HNTE8-45, SHNTE8-45 - Question: What is the function of “reversal” in Tabbed Reversal Brackets?

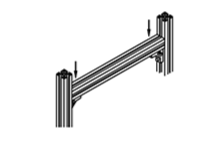

- Answer: The Tabbed Reversal Brackets allows Aluminum extrusions to be connected together in L-connections and Cross-connections. Please see the example below.

Tabbed Reversal Brackets can be used even when the frames intersect. - Question: The allowable load of the bracket is the load under what conditions?

- Answer: It is the load per unit under the condition where two Aluminum extrusions are set up, then another Aluminum extrusion is placed between them with two brackets attached underneath.

The allowable load represents the load that bracket can maintain its position (without breaking/sliding) when all the mounting holes of the bracket are fixed with bolts and the load is applied.

- Question: What is the customizable length of the Aluminum extrusion that available for order?

- Answer: The length betwen 50 to 4000 mm can be ordered.

In addition, depending on the type, it is possible to order length 4001 mm to 6000 mm per Misumi FA catalog. So, please send us a request for quotation via Quotation request for item not listed in MISUMI FA Catalog service. - Question: What are the cutting tolerances of the Aluminum extrusions?

- Answer: ± 0.5 mm of the specified dimension.

- Question: Please explain about the perpendicularity of the cut surface of the Aluminum extrusion.

- Answer: Since the Aluminum extrusion is an extruded material, the datum cannot be specified. Therefore, the perpendicularity of the cut surface cannot be measured.

- Question: What is the product with "K" at the beginning of the Model No. of the Aluminum extrusion?

(Example:KHFS6-3030-4000) - Answer: A fixed-length frame. Available in 2 types: 4000 mm (effective length) and 1000 mm.

- Question: Fixed-length frames of Model No. starts with K are described as "effective length 4000 mm". What does effective length mean?

- Answer: It means that the actual usable length is 4000 mm or more.

Actual size should be 4000 mm or more (a few 10 mm longer).

A fixed-length frame is a frame that is cut and used by the customer, so the exact length cannot be specified. - Question: What is the difference between the Aluminum extrusion 8-series and the 8-45-series?

- Answer: Groove width is the same 1 mm, but the size of outer diameter and depth of groove are different.

Please select accessories that are compatible with each-series. - Question: What is tools for Aluminum extrusion cutting?

- Answer: The Aluminum extrusion can be cut by tip saw for soft steel materials. After assembling the frame, please attach Frame Caps at the cut surface.

- Question: What is the perpendicularity tolerance of the bracket?

- Answer: It depends on the type of bracket.

• Other than extruded brackets: There is no perpendicularity tolerance setting.

• Extruded bracket: Within ± 1 degree according to JIS standard H 4100 special class (excluding right angle machining type).

• Right angle (90 degree Brackets): Tolerance smaller than normal extruded bracket. Please refer to each product page for details. - Question: Is there a bracket for connecting between Aluminum extrusion and plate?

- Answer: Yes.

Please select a bracket with single side tap (HBLFSNK □, HBLFSNE □)

□ is Aluminum extrusion No. - Question: Please explain about the type of frame cap of high-rigidity Aluminum extrusion GFS, GNFS

- Answer: The following products are available:

Frame cap (made of resin):

• 6-series (groove width 8 mm) frame cap for Aluminum extrusion (Frame End Caps - For 6 Series (Slot Width 8mm) Aluminum Frames)

• 8-series (groove width 10 mm) frame cap for Aluminum extrusion (Frame End Caps - For 8 Series (Slot Width 10mm) Aluminum Frames)

High-rigidity plate (made of metal):

• HFCD□ (□ is Aluminum extrusion No.)

GFS and GNFS type have different cross-sectional shapes from other types, so they need to use with special frame caps. - Question: Is there a bracket that can be easily installed after assembly?

- Answer: Yes.

Please check on Panel Brackets - Plastic (HCBR).

It can be installed after assembling the Aluminum extrusion, and the panel can be attached. - Question: Are there any accessories for fixing the cable to the Aluminum extrusion?

- Answer: Yes.

Please check on Cable clamp (HFCN□PACK, HFCC□PACK) Please also be noted that cable band is not included.

□ is Aluminum extrusion No. - Question: Is there a roller that can be used with the Aluminum extrusion?

- Answer: Yes.

Rollers for Aluminum Frames (HFROLL, HFROLLM) or One-Sided Rollers for Aluminum Frames【10 Pieces Per Package】 (HFROLK) - Question: There is something like blue grease on the thread part of the round bar handle with plate. Is there any problem in use?

- Answer: No problem in use.

Since the grease is applied for rust prevention inside the thread part, it can be used normally. - Question: When creating a door using aluminum extrusion, how should the clearance between the door and Aluminum extrusion be?

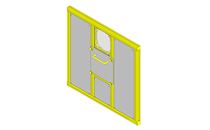

- Answer: Clearance of .the Aluminum extrusion between the door and the outer frame depends on the series of Aluminum extrusions used and the width of the door.

Please refer to the clearance between the door and the outer frame below.

-

- Question: If I specify "with applicable bolts and nuts set"for alteration code of the bracket, can I change only the nuts to a different model number by "change M diameter"?

- Answer: No. In that case, please order separately.

- Question: Is it possible to add a tapped hole to the end face of a flat milled Aluminum extrusion?

- Answer: Yes.

Alteration code LTP (left end face) , RTP (right end face) , and TPW (both end faces) can be specified same as normal Aluminum extrusion. - Question: Is it possible to specify 2 or more types of alteration code on the Aluminum? extrusion?

- Answer: Yes.

Please add on the alteration code numbers side by side.

For example: "HFS6-3030-1000-LTP-RCH" - Question: Is it possible to drill holes with different diameters on one Aluminum extrusion?

- Answer: Not available as a standard product.

- Question: How many additional wrench holes can be specified for the Aluminum extrusion?

- Answer: Up to 5 horizontal, vertical, and cross holes, totally 15 locations.

- Question: Is it possible to peform alteration code (Number of holes, hole position, hole size, etc.) for Aluminum extrusions that are not listed in the "Alteration code" in the Aluminum extrusion page?

- Answer: There is a case where it is possible.

- Question: When using the screw joint HCJ6 with the 6-series Aluminum extrusion, which hole diameter should be used for the additional wrench hole of the Aluminum extrusion between φ5 and φ8?

- Answer: Wrench hole diameter must be φ8.

- Question: Is it possible to make additional 5 holes to the flat frame?

- Answer: Yes.

Up to 5 holes can be added to the flat frame. - Question: Is it possible to paint the Aluminum extrusion?

- Answer: No.

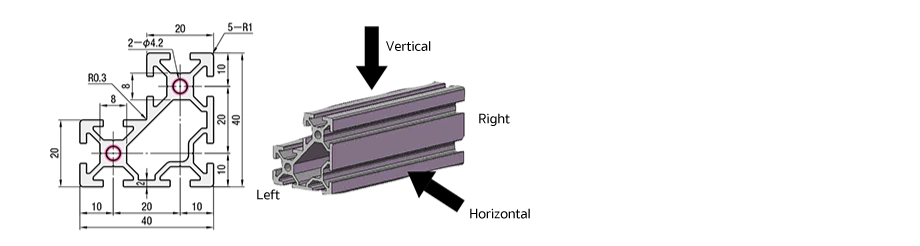

- Question: Please explain about the difference between LMH and LMV of M hole alteration of Aluminum extrusion.

- Answer: LMH is the instruction to make M hole horizontally on the left side of Aluminum extrusion, and LMV is the instruction to make M hole vertically.

(Additional string meaning L:Left, R:Right, H:Horizontal, V:Vertical)

Please refer to the frame placement standard and instructions below.

• Frame placement standard and instructions

When specifying a hole drilling, please specify "which side of the frame should the machining be done (left or right)" and "horizontal or vertical orientation." For MISUMI Aluminum extrusion, after setting in the prescribed way, the right/left/horizontal/vertical are determined as shown in the figure below.

- Question: Can the perpendicularity of the end face of the Aluminum extrusion be improved by specifying the alteration code "SC" (High precision cut) for the flat milled frame?

- Answer: It does not improve perpendicularity.

(The flat milled frame has a top and bottom parallelism of 0.1/100 and a height T of ± 0.05. SC only improves accuracy of length dimension) - Question: Is it possible to make an M6 hole on the side of the bracket?

- Answer: No. The alteration code "C" (alteration code of cover mounting holes) only supports drilling M5 holes.

- Question: Which part of the Aluminum extrusion will be machined if a tapped hole alteration is specified?

- Answer: The machining location is the part surrounded by red circles in the cross-sectional view of the Aluminum extrusion on the product page. There are two types, center hole and square hole, depending on the cross-sectional shape of the Aluminum extrusion.

- Question: Is it possible to insert a Thread Insert by adding tapped holes to the Aluminum extrusion?

- Answer: Yes.

Please refer to the Aluminum extrusion selection information site. If LHP, RHP, or HPW, is selected, alteration code with Thread Insert can be specified. - Question: Is it possible that Thread Insert is inserted even though Thread Insert insertion (LHR, PHP, HPW) is not specified in the tap hole alteration of the Aluminum extrusion?

- Answer: Yes.

In the case of the Aluminum extrusion 8-45-series, Thread Insert can be inserted even if LTP, RTP, or TPW is not specified, but only when the hole size of the tapped hole is φ12.5 - Question: The tolerance for the length of the Aluminum extrusion is ± 0.5 mm. Is it possible to request cutting with more accurate tolerance?

- Answer: Yes.

By specifying the alternation "SC" of the Aluminum extrusion, the tolerance for the total length L dimension can be changed from ± 0.5 to ± 0.2 mm and cut with high accuracy. However, only a length of 1500 mm or less can be performed.

-

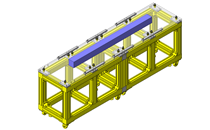

- Question: Please show an example of application on how to attach a linear guide to an Aluminum extrusion.

- Answer: The following is an example of connecting a linear guide using a flat milled frame of an Aluminum extrusion and a long nut.

※The representative product in this example is 6-series, but it can be applied in the same way for Aluminum extrusion and long nut for 5-series and 8-series.

※When using an Aluminum extrusion, please be considering on bending and twisting the material within the range of JIS.

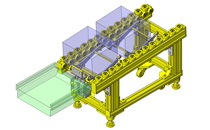

- Question: Please explain about how to mount the Aluminum extrusion vertically on the base plate.

- Answer: There are three methods.

• Set up nut for pre-assembly double joint the base plate and attach the Aluminum extrusion vertically it on the base plate with two bolts of the Aluminum extrusion fitted with lead-in double joint. (Fig.1)

• Make two through holes in the base plate and attach it to the Aluminum extrusion with nuts for lead-in double joint with bolts from under the base plate. (Fig.2)

• Attach with the anchor stand for Aluminum extrusion. (Fig.3)

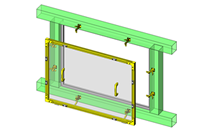

- Question: Please show an example for application of angled Aluminum extrusion (HFS□□A5)

- Answer: The following is an example of application for angle-taped Aluminum extrusion HFS30A5-20.

-

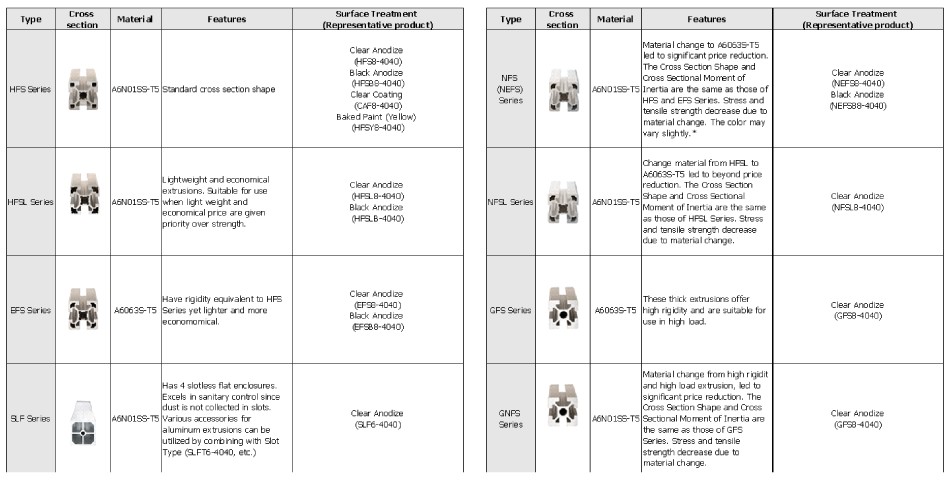

- Question: Please explain about the types and features of Aluminum extrusion.

- Answer: Materials and features are different depending on type of Aluminum extrusion.

Please refer to the table below.

• Aluminum Extrusion Type and Characteristics

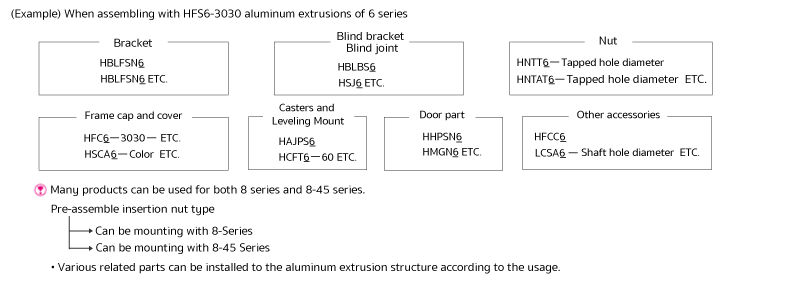

The color of aluminum extrusion may slightly vary depending on the materials. - Question: Please explain about how to select accessories for Aluminum extrusions.

- Answer: When the Aluminum extrusion is selected, available peripheral parts No. will be determined. Use the No. as a guide to select accessories.

• Selection of peripheral parts

When the Aluminum extrusion is selected, available peripheral parts No. will be determined. Use the No. as a guide to select accessories.

- Question: Please explain about how to secure the panel to the Aluminum extrusion.

- Answer: There are three methods of securing the panel to the Aluminum extrusion: bracket mounting, groove fitting, and direct mounting.

- Question: what's the difference between bolt and screw?

- Answer: The screw looks like a bolt, however, it has a shaped tip. The thread of the screw mate with the material. It is turned through to hold the screw in materials such as wood and plastic without using a nut

On the other hand, the bolt is not designed for self-tapping material, so that requires a nut to hold the bolt and object together - Question: Which is nut and which is bolt?

- Answer: The easy way to categorized between nut and bolt is

– Nuts have a screw hole,which has thread inside for example Hex nuts, Flanged nuts, Square nut and etc

– Bolts have an external male thread, which always use with nuts or screw hole for example Hex bolt, T-Bolt , Eye bolt etc. - Question: How many nut types are there?

- Answer: Nuts have varieties of types, sizes and materials for example,

Nut for aluminum profile can categorized by 2 types

1. Post-Assembly: Mountable from slots after assembly such as Free nut, Special T-nuts , Leaf spring T-nut, Ball spring T-nut, T- bolt and so on

2. Pre-Assembly: Insert from the slot ends before assembly such as T-nut, Long T-nut, T-nut with stopper , T-nut with set screw etc. - Question: Does a screw need a nut?

- Answer: When you use screws don't need to use nuts, because the screw has threads spiraling along the length, which can drill and stick to the material without using a nut. On the other hand, bolts need to use with nuts to hold two or more objects together.

- Question: How do you fasten nuts properly?

- Answer: 1. Before using a nut and a bolt need to check both of them have the same size of threads and pitch, for example, bolt size M8x1.5 and nut size M8x1.5 is OK

2. Use hands for tight a bolt and a nut mate together

3. Use a wrench or hex socket wrench to fasten it until tight

How can we improve?

How can we improve?