(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

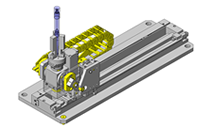

TSUBAKIMOTO Cable Carriers(Bending Radius R:60/75/90/125/150/200)

TSUBAKIMOTO offers products Cable Carriers specified by Bending Radius R 60/75/90/125/150/200 from Automation Components product category. There are a total of 1 items. Search and select detailed specifications of parts for your machine with free CAD downloads. TSUBAKIMOTO products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Configure

Specification/Dimensions

-

Inner Height H1(mm)

-

Inner Width W1(mm)

-

Bending Radius R(mm)

- 10

- 12

- 15

- 18

- 18/20/28/37

- 19

- 25

- 28

- 28/37/50

- 30

- 31

- 34

- 35

- 36

- 37

- 37/50/75

- 38

- 40

- 45

- 48

- 48/60/75/100/125

- 50

- 50/75/95/125/150/200

- 55

- 58

- 60

- 60/75/90/125/150/200

- 63

- 70

- 70/100/150

- 75

- 75/90/125/150/200

- 75/100/125/150/200/250

- 85

- 90

- 95

- 100

- 110

- 120

- 125

- 140

- 145

- 150

- 160

- 175

- 180

- 200

- 225

- 250

- 300

- 350

- 400

- 500

- Joints in one set

-

Properties

- Standard

- Low Particle Generation

- Low Noise

- Low Friction

- Low Vibration

- High Endurance

-

Cover Type

-

Type

-

Pitch P(mm)

-

Number of Divided Sections inside Carrier

-

Cable Insertion Type

-

Max. Cable O.D. Dp(Ø)

-

Cable Insertion Surface

-

Operating Speed(m/s)

Brand |

|

|---|---|

| CAD |

|

- 1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

TKP Model Plastic Cableveyor (TKP58H39 Model)

TSUBAKIMOTO

[Features]

· Easy to handle with wide range from small to large sizes

· Pitch 58 mm, internal height 39 mm

· Maximum stroke 4.3 mFrom: ฿ 22.08 Days to Ship: 5 Day(s)

5 Day(s)

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Inner Height H1(mm) |

| Inner Width W1(mm) |

| Bending Radius R(mm) |

| Properties |

| Cover Type |

| Type |

| Pitch P(mm) |

| Number of Divided Sections inside Carrier |

| Cable Insertion Type |

| Max. Cable O.D. Dp(Ø) |

| Cable Insertion Surface |

| Operating Speed(m/s) |

You can add up to 6 items per a category to the compare list. | |

| Brand | TSUBAKIMOTO |

| Product Series | |

| From | ฿ 22.08 |

| Days to Ship | 5 Day(s) |

| Inner Height H1(mm) | 39 |

| Inner Width W1(mm) | 50 ~ 125 |

| Bending Radius R(mm) | 60/75/90/125/150/200 |

| Properties | Standard |

| Cover Type | Standard |

| Type | Related Components |

| Pitch P(mm) | - |

| Number of Divided Sections inside Carrier | - |

| Cable Insertion Type | - |

| Max. Cable O.D. Dp(Ø) | 35 |

| Cable Insertion Surface | - |

| Operating Speed(m/s) | - |

Loading...

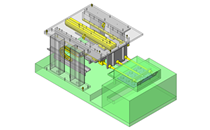

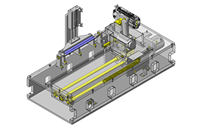

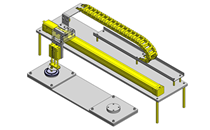

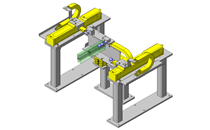

Application example related to this category

Related Categories to Cable Carriers

FAQ Cable Carriers

- Question: What are cable carriers, and how do they work?

- Answer: Cable carriers, also known as energy chains or drag chains, are flexible chain-like structures designed to organize and protect cables and hoses in motion-intensive applications. They work by guiding and supporting cables along predefined paths, preventing tangling and damage.

- Question: What materials are cable carriers made of?

- Answer: Cable carriers are typically made of durable materials such as plastic, steel, or aluminum. These materials are chosen for their strength, flexibility, and resistance to environmental factors like heat, chemicals, and abrasion.

- Question: What industries use cable carriers?

- Answer: Cable carriers and tracks are widely used in various industries, including automation, robotics, material handling, machine tools, and packaging. They are essential components for managing cables and hoses in motion-intensive applications.

- Question: How's different between tracks and cable carriers?

- Answer: Cable tracks, also known as cable trays or cable channels, are stationary structures designed to guide and protect cables along fixed paths. Unlike cable carriers, which are flexible and movable, cable tracks are typically mounted to machinery or structures.

- Question: What are hose carriers, and where are they used?

- Answer: Hose carriers, also called hose reels or hose management systems, are specialized devices designed to organize and protect hoses in industrial environments. They are commonly used in applications involving pneumatic, hydraulic, or fluid transfer systems.

- Question: What are the benefits of using cable carriers and tracks?

- Answer: Using cable carriers and tracks offers several benefits, including improved cable management, reduced downtime due to cable failures, extended cable lifespan, and enhanced safety by preventing accidents caused by loose cables.

- Question: How do I choose the right cable carrier for my application?

- Answer: When selecting a cable carrier, consider factors such as the weight and diameter of the cables, the length of the travel distance, the operating environment (e.g., temperature, humidity, presence of chemicals), and any specific requirements of your application.

- Question: Can customize cable carriers for specific requirements?

- Answer: Yes, many cable carrier manufacturers offer customizable solutions tailored to the unique needs of each application. This may include custom lengths, widths, heights, mounting options, and additional features such as strain relief and cable separation.

- Question: How to install and maintain cable carriers and tracks?

- Answer: Installation and maintenance procedures for cable carriers and tracks vary depending on the specific design and manufacturer. Generally, it involves securing the carriers or tracks to the machinery, inspecting them regularly for signs of wear or damage, and lubricating moving parts as needed.

- Question: Where can I purchase cable carriers and track?

- Answer: Cable carriers and tracks are available from various suppliers and distributors specializing in automation and machinery components or online platforms like MISUMI website that's offer a wide range of options to choose from, including different sizes, materials, and configurations.

How can we improve?

How can we improve?