(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 28/7/2024 to 6:00 29/7/2024. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

THK Spline Shaft

Spline Shaft products in the Automation Components category from THK. The product can be selected based on many product specifications such as Nut Type, Type, Nut Length, Nut Overall Length L1, Nut Outer Dia. D1. THK offers products around 2 items and the product specifications can easily be compared. Search and select detailed specifications of parts for your machine with free CAD downloads. THK products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Configure

Specification/Dimensions

-

Spline Shaft Outer Dia. D(Ø)

-

Type

-

Nut Length

-

Nut Overall Length L1(mm)

-

Nut Outer Dia. D1(Ø)

-

Preload

-

Accuracy Grade

-

End Shape (Left)

-

Standard

Standard -

Tapped

Tapped -

Stepped

Stepped -

Stepped and Tapped

Stepped and Tapped -

Stepped and Threaded

Stepped and Threaded

-

-

End Shape (Right)

-

Standard

Standard -

Tapped

Tapped -

Stepped

Stepped -

Stepped and Tapped

Stepped and Tapped -

Stepped and Threaded

Stepped and Threaded

-

-

Torque

- High Torque

- Middle Torque

-

Shaft material

- SCM415 Equivalent

- SUJ2

- SUS440C Equivalent

- SUS304

- SUJ2 Equivalent

-

Number of Nuts(pc(s).)

|

Nut Type

|

|

|---|---|

Brand |

|

Filter By |

|

| CAD |

|

| Days to Ship |

|

- 2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Until 31/03/2025

Until 31/03/2025 Until 31/03/2025

Until 31/03/2025THK

The nut and shaft are sold separately. Use THK nut and shaft (DPM, DP, SS) as a set. No surface treatment is given to the cut shaft ends.

[Features]

· The spline nut DPM type / DP type is a low-priced bearing where a special alloy has been die-cast with a high-accuracy splint shaft as the core.

· Unlike conventional machined products, the sliding surface retains a chill layer formed during casting, which is superior in abrasion-resistance.

· The combined spline shaft surface is machined and hardened by rolling, and also the surface is mirror finished, resulting in smooth sliding.

· The spline cog has a special design with a large contact area and has concentricity that can automatically determine the core when torque is incurred, so the torque transmission is stable.

· Special rolling shaft features: Spline nut is provided with a dedicated rolling shaft of standard length.

· Improved abrasion-resistance: Cold rolled tooth shaft with tooth surface hardened to 250 HV or more and finished to a smooth mirror finish for superior abrasion-resistance. Extremely smooth movement when used in combination with nuts.

· Improved mechanical properties: Because of the internal tooth structure of the rolled shaft, the fiber flow occurs along the tooth contours for tight rooted teeth with greater endurance strength.

· Alteration of shaft end support: The rolled shaft with altered shaft end support bearing part is easier to use in turning and milling.From: ฿ 552.00 Special Price Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

Medium-Torque Type, Flange Type Ball Spline, LF Type

THK

[Features]

· Easy to assemble because it can be fixed by bolts to the housing using the flange.

· Ideal for housings with small widths or where there are concerns of deformation associated with machining keyway into the housing.Days to Ship: 19 Day(s)

19 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Nut Type |

| Spline Shaft Outer Dia. D(Ø) |

| Type |

| Nut Length |

| Nut Overall Length L1(mm) |

| Nut Outer Dia. D1(Ø) |

| Preload |

| Accuracy Grade |

| End Shape (Left) |

| End Shape (Right) |

| Torque |

| Shaft material |

| Number of Nuts(pc(s).) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | THK | THK |

| Product Series | ||

| CAD |

|

|

| From | ฿ 552.00 Special Price On Sale Until 31/03/2025 | |

| Days to Ship | Same day | 19 Day(s) |

| Nut Type | - | Flanged Type |

| Spline Shaft Outer Dia. D(Ø) | - | - |

| Type | Polygonal | Solid / Hollow / Hollow (Thin) |

| Nut Length | - | Standard |

| Nut Overall Length L1(mm) | - | 125 |

| Nut Outer Dia. D1(Ø) | - | 80 |

| Preload | - | Standard / Light Preload / Medium Preload |

| Accuracy Grade | - | Standard Grade / High Grade / Precision Grade |

| End Shape (Left) | Standard | Standard |

| End Shape (Right) | Standard | Standard |

| Torque | - | Middle Torque |

| Shaft material | - | - |

| Number of Nuts(pc(s).) | - | 1 ~ 5 |

Loading...

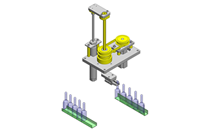

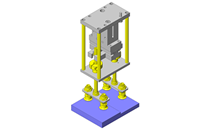

Application example related to this category

Related Categories to Spline Shaft

FAQ Spline Shaft

- Question: What are spline shafts and their primary function in linear motion?

- Answer: Spline shafts are cylindrical rods with ridges or teeth along their length, known as splines. Their primary function in linear motion is to convert rotational motion into smooth and precise linear movement. These splines engage with complementary components to transmit torque efficiently, ensuring controlled motion without slipping or backlash. Spline shafts are crucial in various machinery applications where accurate linear motion is required, such as moving heavy loads or guiding tools with precision, providing reliable and efficient motion control.

- Question: Can you explain the key characteristics of square splines?

- Answer: Square splines feature square-shaped ridges and slots, offering efficient torque transmission and precise alignment. Their design allows for high torque capacity and compatibility with various mating components. Due to their simplicity of manufacture, they are cost-effective for many applications. Additionally, the even distribution of wear along the mating surfaces enhances durability. Square splines are widely used in industrial and mechanical systems where accurate motion control and reliable torque transmission are essential.

- Question: What role do spline shafts play in automotive transmissions?

- Answer: Spline shafts are essential in automotive transmissions for transferring power from the engine to the wheels. They connect parts like the clutch and gears, ensuring smooth power transmission. By enabling the engine's rotational motion to move the wheels with precision, they allow the vehicle to accelerate, decelerate, and shift gears seamlessly. Essentially, spline shafts ensure that your car moves smoothly and efficiently, contributing to its overall performance and driving experience.

- Question: What factors should be considered when choosing a spline shaft?

- Answer: When selecting a spline shaft, it's important to consider factors like the application's torque, speed, and precision requirements. Choose a spline profile and dimensions that match mating components to ensure efficient power transmission. Material selection is key for strength and corrosion resistance. The surface finish impacts durability, while manufacturing methods and costs should be evaluated. Supplier reliability is also crucial. By carefully considering these factors, you can choose a spline shaft that meets your application's needs effectively, ensuring optimal performance and longevity.

- Question: What materials are commonly used for manufacturing spline shafts?

- Answer: Spline shafts are commonly made from materials like steel, aluminum, brass, bronze, titanium, and plastics. Steel offers strength and durability, while aluminum is lightweight. Brass and bronze provide corrosion resistance. Titanium is strong and corrosion-resistant, ideal for demanding environments. Plastics offer benefits like low friction and electrical insulation. The choice depends on factors such as strength, corrosion resistance, weight, and cost.

- Question: What are the maintenance requirements for spline shafts?

- Answer: Maintaining spline shafts involves regular checks for wear, damage, and corrosion. Keep them lubricated to reduce friction and ensure smooth operation. Clean them regularly to prevent dirt buildup. Properly align mating components to avoid unnecessary stress on the shafts. Promptly replace any worn or damaged shafts to prevent further issues. Protect spline shafts from harsh environments and store them correctly when not in use. Following these steps will help ensure the longevity and efficient performance of spline shafts in machinery and equipment.

- Question: How do nut types of influence spline shaft functionality?

- Answer: The type of nut used can significantly affect spline shaft functionality. Slotted nuts provide anti-rotation, ensuring the nut and shaft move together for enhanced torque transmission. Hex nuts offer stability with six sides but lack anti-rotation features. Lock nuts prevent unintentional loosening, employing mechanisms like nylon inserts or serrations. Flange nuts distribute load over a wider area with a built-in washer-like flange. Self-locking nuts have integrated locking features to prevent loosening due to vibrations or external forces. Each type suits specific applications based on torque requirements, environmental conditions, and space constraints.

How can we improve?

How can we improve?