(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- การยกเลิกจำหน่ายสินค้าประเภทอุปกรณ์นิวเมติกส์ (Pneumatic equipment) รุ่น “Economy Series” | Notice of End of Sales for Economy Series Pneumatic Equipment Category > คลิก

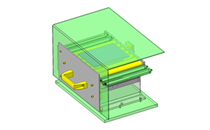

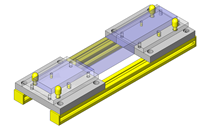

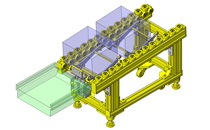

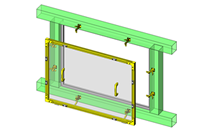

SUS Handles(Type:Arch Shape)

SUS offers products Handles specified by Type Arch Shape from Automation Components product category. There are a total of 1 items. Search and select detailed specifications of parts for your machine with free CAD downloads. SUS products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Configure

Specification/Dimensions

-

Mounting Method

-

Tapped

Tapped -

Round Holes

Round Holes

-

|

Type

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

- 1 items

- Sort By

-

RecommendedYou can add up to 6 items per a category to the compare list.

SUS

SF standard parts. Mounting method: female thread. Material: (main body) polycarbonate / (tap part) brassFrom: ฿ 90.75 Days to Ship: Same day

Same day

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Type |

| Mounting Method |

You can add up to 6 items per a category to the compare list. | |

| Brand | SUS |

| Product Series | |

| CAD |

|

| From | ฿ 90.75 |

| Days to Ship | Same day |

| Type | Arch Shape |

| Mounting Method | Tapped |

Loading...

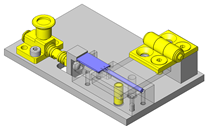

Related Categories to Handles

-

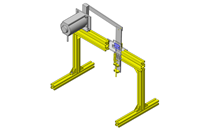

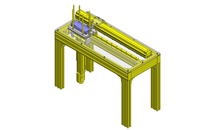

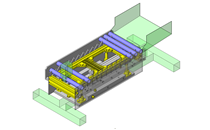

- Aluminum Frames

- Special AEX

- AEX Units

- Brackets and Joint Parts

- Nuts

- Bolts

- Frame Caps

- Slot Covers

- Handles

- Hinges

- Catches and Locks

- Casters

- Foot Bases for Aluminum Extrusions

- Adjuster Pads

- Panel Mounts

- Curtains, Sheets

- Door Sliders

- Conveyor Parts

- Clamps, Holders, Hooks

- Jigs, Maintenace Parts

- Transparent Plastic Covers

- Perforated Metals, Fences, Nets, Panels

-

FAQ Handles

- Question: How do I choose the correct handle for my aluminum frame application?

- Answer: To select the appropriate handle, consider the following factors:

- Mounting Method: Determine whether you need handles with tapped holes or round holes for mounting.

- Type and Shape: Choose the handle type (U-shape, arch shape, etc.) based on the design and ergonomic requirements.

- Material: Select the material that best suits your environment, such as polycarbonate for lightweight applications or stainless steel for high-strength and corrosion resistance. - Question: What materials are handles for aluminum frames made from?

- Answer: Handles are made from various materials, including polycarbonate, aluminum alloy, stainless steel, and nylon. The choice of material depends on the application requirements, such as load capacity, environmental conditions, and aesthetic preferences.

- Question: What are the benefits of using aluminum handles in industrial applications?

- Answer: Aluminum handles are lightweight, durable, and corrosion-resistant, making them ideal for industrial applications. They offer high strength-to-weight ratios and can be easily mounted on aluminum extrusions, providing reliable and long-lasting solutions.

- Question: Can handles be customized for specific applications?

- Answer: Yes, many handles can be customized in terms of length, mounting hole configurations, and finishes. Customization options allow for better integration into specific design requirements and improved functionality.

- Question: How are handles typically mounted on aluminum frames?

- Answer: Handles can be mounted using tapped holes or round holes, depending on the design. Some handles come with dedicated plates or washers for easy installation, ensuring a secure fit on the aluminum frames.

- Question: Are there handles specifically designed for heavy-duty applications?

- Answer: Yes, handles made from materials like stainless steel or die-cast aluminum are designed for heavy-duty applications. These handles offer high load-bearing capacity and durability, making them suitable for industrial environments where strength and reliability are crucial.

- Question: What are some common applications for these handles?

- Answer: Handles for aluminum frames are commonly used in machinery, industrial equipment, enclosures, and panel doors. They provide convenient and ergonomic grip points for operators, enhancing usability and safety.

- Question: How do I ensure proper maintenance of handles in industrial settings?

- Answer: Regular inspection and cleaning are essential for maintaining handles in industrial settings. Ensure that mounting bolts are securely tightened and check for any signs of wear or damage. Depending on the material, use appropriate cleaning agents to avoid corrosion and prolong the handle's lifespan.

How can we improve?

How can we improve?