(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 8/9/2024 to 5:00 9/9/2024. We apologize for the inconvenience.

- การยกเลิกจำหน่ายสินค้าประเภทอุปกรณ์นิวเมติกส์ (Pneumatic equipment) รุ่น “Economy Series” | Notice of End of Sales for Economy Series Pneumatic Equipment Category > คลิก

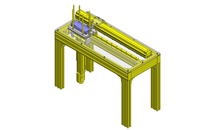

NIC AUTOTEC Angular Brackets(Extrusion Series:NIC Autotec M8 Series)

NIC AUTOTEC offers products Angular Brackets specified by Extrusion Series NIC Autotec M8 Series from Automation Components product category. There are a total of 2 items. Search and select detailed specifications of parts for your machine with free CAD downloads. NIC AUTOTEC products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Brand |

|

|---|---|

| CAD |

|

- 2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

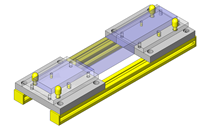

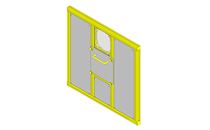

M6 Series/M8 Series V Bracket (45°)

NIC AUTOTEC

Bracket to fix frames whose edges are tapped at 45 degrees.

[Features]

· Made from aluminum (A6063S-T5).

Anodizing is the surface treatment.

· The bolt and nut set available from BNH, CNH, BNHS and CNHS.

[Applications]

· Cover material for cover of factory automation equipment.

· For display stand cover component.

· For work bench component.

· For frame component.From: ฿ 371.88 Days to Ship: 3 Day(s)

3 Day(s)

-

You can add up to 6 items per a category to the compare list.

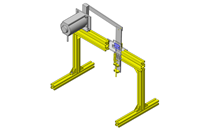

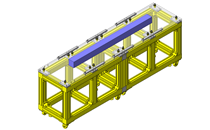

NIC AUTOTEC

Bracket for freely fixing the angle of the frame whose edges are tapped.

[Features]

· Material: zinc die-cast.

· Fastening bolts are made of steel.

· Both right and left pointing are available.

· Structural element for factory automation equipment.

[Applications]

· Cover material for factory automation equipment.

· Component members for display stand covers, work benches or frames.From: ฿ 989.57 Days to Ship: 3 Day(s)

3 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Extrusion Series |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | NIC AUTOTEC | NIC AUTOTEC |

| Product Series | ||

| CAD |

|

|

| From | ฿ 371.88 | ฿ 989.57 |

| Days to Ship | 3 Day(s) | 3 Day(s) |

| Extrusion Series | NIC Autotec M8 Series | NIC Autotec M8 Series |

Loading...

Related Categories to Angular Brackets

FAQ Angular Brackets

- Question: What are metal brackets used for?

- Answer: Metal brackets are used to fasten or reinforce frames made from extruded aluminum extrusions. They come in various shapes and sizes to match different connection points or reinforcement areas. Common types include square, L-shaped, bent, T-shaped, and corner brackets.

- Question: What materials are metal brackets made from?

- Answer: Metal brackets are available in steel and stainless steel, providing options based on strength requirements and environmental conditions.

- Question: Can metal brackets be used with different aluminum extrusion series?

- Answer: Yes, metal brackets can be used with different series of aluminum extrusions, such as HFS5, HFS6, HFS8, NIC Autotec M6, M8, and SUS SF20, SF30, SF40, and SF45 series.

- Question: What are the load capacities of metal brackets?

- Answer: The load capacity of metal brackets depends on their design and the specific application. It is essential to refer to the product specifications to determine the allowable load for each bracket type under specific conditions.

- Question: How do I choose the right metal bracket for my application?

- Answer: To choose the correct metal bracket, consider the following:

- Shape: Determine the shape needed for your connection (square, L-shaped, bent, T-shaped, or corner).

- Material: Select between steel or stainless steel based on the strength requirements and environmental exposure.

- Series Compatibility: Ensure the bracket is compatible with the aluminum extrusion series you are using.

- Load Capacity: Check the load capacity requirements for your application and match them with the bracket's specifications. - Question: Are there brackets that can be installed after frame assembly?

- Answer: Yes, post-assembly insertion type brackets, such as blind brackets, are designed to be installed after the frame assembly. These brackets provide a clean and streamlined appearance as the connections are made inside the aluminum extrusion.

- Question: What is the installation process for metal brackets?

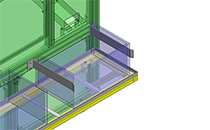

- Answer: Metal brackets are typically installed using bolts and nuts. The exact installation process may vary depending on the bracket type and application. Ensure all mounting holes are properly aligned and secured with the appropriate fasteners.

- Question: Can metal brackets be customized?

- Answer: Yes, many metal brackets can be customized in terms of dimensions and hole patterns. This allows for specific configurations to meet unique application requirements.

- Question: Are there brackets for connecting aluminum extrusions to plates?

- Answer: Yes, specific brackets are designed for connecting aluminum extrusions to plates. For example, single-side tap brackets can be used for such connections.

- Question: How should metal brackets be maintained?

- Answer: Regular maintenance includes checking for any signs of wear or damage and ensuring that all fasteners are tight. Cleaning methods depend on the bracket material; for instance, stainless steel brackets may require specific cleaning agents to prevent corrosion.

- Question: Are there any special cleaning methods for metal brackets?

- Answer: Yes, there are different cleaning methods available, such as degreasing, precision cleaning, and electrolytic polishing. These methods help maintain the bracket's integrity and appearance, especially in environments requiring high cleanliness standards.

How can we improve?

How can we improve?