(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน มิถุนายน 2567 | Notice holiday in June 2024 > คลิก

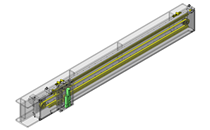

MITSUBOSHI BELTING Timing Pulleys, Idlers(Belt Series:S3M)

MITSUBOSHI BELTING offers products Timing Pulleys, Idlers specified by Belt Series S3M from Automation Components product category. There are a total of 3 items. Search and select detailed specifications of parts for your machine with free CAD downloads. MITSUBOSHI BELTING products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Configure

Specification/Dimensions

-

Belt Series

-

Belt Width Used (mm)(mm)

-

Number of Teeth(T)

-

Pulley Shape

-

Material

- Steel

- Aluminum

- Stainless Steel

- Plastic

-

Belt Width Used(Inch)(Inch)

-

Surface Treatment

|

Type

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

- 3 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

MITSUBOSHI BELTING

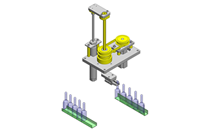

Easy specification of shaft hole type/diameter. MISUMI can machine the shaft hole for the pulley of the Mitsuboshi belt without drawings for delivery.From: ฿ 472.98 Days to Ship: 3 Day(s)

3 Day(s)

-

You can add up to 6 items per a category to the compare list.

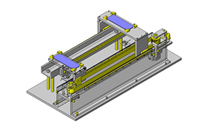

MITSUBOSHI BELTING

It can be used as a part of the transmission mechanism together with the timing belt.

[Features]

· Timing pulley with shaft holes, keys and taps. It can be used immediately without hassle.

· Surface treatment and flange caulking can be selected to meet various needs.

[Application]

-Use in a wide range of equipment from large machines such as machine tools and injection molding machines to office automation equipment such as copiers and printers.From: ฿ 913.91 Days to Ship: 7 Day(s)

7 Day(s)

-

You can add up to 6 items per a category to the compare list.

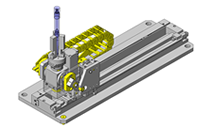

MITSUBOSHI BELTING

It can be used as a part of the transmission mechanism together with the timing belt.

[Features]

· Timing pulley with shaft holes, keys and taps. It can be used immediately without hassle.

· Surface treatment and flange caulking can be selected to meet various needs.

[Application]

-Use in a wide range of equipment from large machines such as machine tools and injection molding machines to office automation equipment such as copiers and printers.From: ฿ 1,074.67 Days to Ship: 7 Day(s)

7 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Type |

| Belt Series |

| Belt Width Used (mm)(mm) |

| Number of Teeth(T) |

| Pulley Shape |

| Material |

| Belt Width Used(Inch)(Inch) |

| Surface Treatment |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MITSUBOSHI BELTING | MITSUBOSHI BELTING | MITSUBOSHI BELTING |

| Product Series | |||

| CAD |

|

|

|

| From | ฿ 472.98 | ฿ 913.91 | ฿ 1,074.67 |

| Days to Ship | 3 Day(s) | 7 Day(s) | 7 Day(s) |

| Type | Timing Pulley | Timing Pulley | Timing Pulley |

| Belt Series | S3M | S3M | S3M |

| Belt Width Used (mm)(mm) | 10 ~ 15 | 10 | 15 |

| Number of Teeth(T) | 14 ~ 60 | 14 ~ 60 | 14 ~ 60 |

| Pulley Shape | Shape A / Shape B / Shape C | Shape A / Shape B / Shape C | Shape A / Shape B / Shape C |

| Material | Aluminum | Aluminum | Aluminum |

| Belt Width Used(Inch)(Inch) | - | - | - |

| Surface Treatment | Not Provided | Not Provided / Clear Anodize | Not Provided / Clear Anodize |

Loading...

Related Categories to Timing Pulleys, Idlers

FAQ Timing Pulley

- Question: What are pulleys used for?

- Answer: Pulleys designed for belt transmission facilitate the transfer of rotational motion and power among multiple shafts and belts, serving various industries. They enable speed and torque adjustment, change motion direction, guide the belt to maintain alignment and prevent slippage.

- Question: What benefits do pulleys offer?

- Answer: Pulleys offer several benefits in engineering applications:

1.Power transmission: They efficiently transfer rotational motion and power between shafts through the use of belts.

2. Speed and torque adjustment: Pulleys of different sizes allow engineers to adjust the speed and torque in belt drive systems, adapting them to specific requirements.

3. Belt tensioning: They help maintain proper belt tension, ensuring optimal power transfer and preventing slipping between the belt and pulleys.

4. Direction change: Pulleys enable the redirection of rotational motion, allowing for the driving of components located in different directions within a system.

5. Belt guidance and alignment: They guide the belt, keeping it aligned and preventing it from slipping off the pulley, ensuring reliable and smooth operation. - Question: Why are pulleys better than gears?

- Answer: 1.Simplicity installation : Pulleys have a simpler design and operation compared to gears. They consist of a grooved wheel and a belt, making them easier to install, and maintain. Gears, on the other hand, require precise tooth profiles and arrangements, adding complexity.

2.Noise and Vibration: Pulleys generally produce less noise and vibration compared to gears. The direct contact between gear teeth can create noise, particularly at high speeds. In contrast, pulleys that use a belt or rope for motion transfer offer smoother operation, resulting in reduced noise and vibration levels.

3.Misalignment Tolerance Available: Pulleys can accommodate a certain degree of misalignment between the driving and driven shafts. This flexibility is valuable in situations where precise alignment is challenging. Gears, on the other hand, require more precise alignment for optimal performance and can be sensitive to misalignment.

4.Overload Protection: Pulleys can provide some level of overload protection due to the slipping action of the belt. If the load exceeds a certain threshold, the belt may slip on the pulley, preventing damage to the system. Gears do not offer this slipping action and are more prone to damage when subjected to excessive loads.

It's important to recognize that gears have their own advantages, such as higher precision, greater efficiency, and the ability to transmit higher torque loads. The choice between pulleys and gears depends on the specific requirements of the application, including factors like load capacity, precision, speed control, and cost considerations. - Question: What are the 3 types of pulleys?

- Answer: 1. V-Belt Pulley: This type of pulley utilizes V-belts, which have a trapezoidal cross-section. V-belts fit into the grooves of the pulleys, creating friction and transmitting power. V-belt pulley transmissions are widely used in various applications, including automotive engines, industrial machinery, and HVAC systems.

2. Flat Belt Pulley: In a flat belt pulley a flat belt is used to transmit power between the pulleys. Flat belt pulley transmissions are often employed in agricultural machinery, textile mills, and other industrial applications.

3. Timing Belt Pulley: Timing belt pulley use toothed belts, known as timing belts, that have teeth on the inner surface. These teeth mesh with corresponding grooves on the pulleys, ensuring precise and synchronous power transmission. Timing belt pulley transmissions are commonly found in engines, camshaft drives, and other systems that require accurate timing. - Question: What are the advantages of a pulley?

- Answer: 1.Speed variation: Pulley power transmissions allow for speed variation by using pulleys of different sizes or adjusting the pulley ratio. This flexibility enables the adaptation of rotational speed to match specific operational requirements, providing optimal performance.

2.Directional flexibility: Pulleys provide the ability to change the direction of power transmission. This flexibility allows for versatile routing of power.

3.Quiet and smooth operation: Pulley power transmissions typically operate with minimal noise and vibration. The smooth transfer of power between pulleys results in quieter and more comfortable operation.

4.Cost-effectiveness: Pulley power transmissions are cost-effective due to their simplicity, and ease of installation. They require minimal maintenance, reducing overall machine system costs.

How can we improve?

How can we improve?