(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 28/7/2024 to 6:00 29/7/2024. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

MISUMI Timing Pulleys, Idlers(Pulley Shape:Shape A)

Configure

Specification/Dimensions

-

Belt Series

-

Belt Width Used (mm)(mm)

-

Number of Teeth(T)

-

Pulley Shape

-

Material

- Steel

- Aluminum

- Stainless Steel

- Plastic

-

Belt Width Used(Inch)(Inch)

-

Surface Treatment

|

Type

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

- 32 items

- Sort By

-

RecommendedYou can add up to 6 items per a category to the compare list.

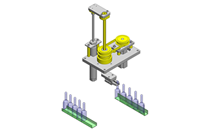

Timing Pulleys S5M

Timing Pulleys S5M

Timing Pulleys are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Belt Width Used (mm.) : 10, 15 and 20

● Applicable with Belt Type : S5M

● Number of Teeth Minimum/Maximum : 14 and 36

● Shaft Bore Diameter Minimum/Maximum (mm.) : 5 to 30

● Shaft Bore Specs. : Can select between Round Hole, Round Hole + Tap and New JIS keyway + Tap

● Material : Aluminum Alloy

● Surface treatment : Clear Anodized

[Application]

Timing pulleys are frequently utilized in systems that incorporate timing belts to regulate and govern the movement of the machinery.From: ฿ 191.68 Days to Ship: Same day

Same day

-

RecommendedYou can add up to 6 items per a category to the compare list.

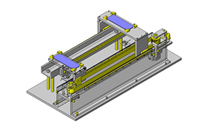

Timing Pulleys T10

Timing Pulleys T10

Timing Pulleys are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Belt Width Used (mm.) : 15, 20,25, 30, 40 and 50

● Applicable with Belt Type : T10

● Number of Teeth : 14, 16, 18 and 20

● Shaft Bore Diameter Minimum/Maximum (mm.) : 10 to 25

● Shaft Bore Specs. : Can select between Round Hole + Tap and New JIS keyway + Tap

● Material : Aluminum Alloy

● Surface treatment : Clear Anodized

[Application]

Timing pulleys are frequently utilized in systems that incorporate timing belts to regulate and govern the movement of the machinery.From: ฿ 281.83 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

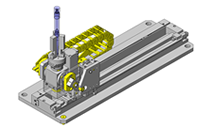

High Torque Timing Pulleys S5M Type

MISUMI

[Material]

· Pulley: Aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC, SUS304

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black iron oxide coating

[Related Products]

· Timing belt High Torque Timing Belt, Long Timing Belts-Polyurethane, Open End Belts/Polyurethane/Chloroprene Rubber

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

MISUMI

[Material]

· Pulley: Aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black oxide

[Related Products]

· Timing belt Timing Belt, Timing Belts with Attachment, Long Timing Belts-Iron Rubber, Long Timing Belts-Polyurethane, Open End Belt Iron Rubber, Open End Belts/Polyurethane/Chloroprene Rubber

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

MISUMI

[Material]

· Pulley: Aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black oxide

[Related Products]

· Timing belt High Torque Timing Belt, High Torque Timing Belts with Attachment, Long Timing Belts-Iron Rubber, Long Timing Belts-Polyurethane, Open End Belt Iron Rubber, Open End Belts/Polyurethane/Chloroprene Rubber

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

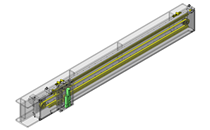

High Torque Timing Pulleys S8M Type

MISUMI

[Material]

· Pulley: Extra super duralumin aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black iron oxide coating

[Related Products]

· Timing belt High Torque Timing Belt, Super High Torque Timing Belt, Long Timing Belts-Polyurethane, Open End Belts/Polyurethane/Chloroprene Rubber

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 4 Day(s)

4 Day(s)

-

Economy seriesYou can add up to 6 items per a category to the compare list.

Timing Pulleys S3M

Timing Pulleys S3M

Timing Pulleys are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Belt Width Used (mm.) : 6, 10 and 15

● Applicable with Belt Type : S3M

● Number of Teeth Minimum/Maximum : 14 to 48

● Shaft Bore Diameter Minimum/Maximum (mm.) : 4 to 20

● Shaft Bore Specs. : Can select between Round Hole, Round Hole + Tap and New JIS keyway + Tap

● Material : Aluminum Alloy

● Surface treatment : Clear Anodized

[Application]

Timing pulleys are frequently utilized in systems that incorporate timing belts to regulate and govern the movement of the machinery.From: ฿ 185.63 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

High Torque Timing Pulleys S3M Type

MISUMI

[Material]

· Pulley: Aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC, SUS304

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black iron oxide coating

[Related Products]

· Timing belt High Torque Timing Belt, Open End Belts/Polyurethane/Chloroprene Rubber

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

MISUMI

[Material]

· Pulley: Extra super duralumin aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC,

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black iron oxide coating

[Related Products]

· Timing belt Timing Belt, Long Timing Belts-Iron Rubber, Long Timing Belts-Polyurethane, Open End Belt Iron Rubber, Open End Belts/Polyurethane/Chloroprene Rubber

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 5 Day(s)

5 Day(s)

-

Economy seriesYou can add up to 6 items per a category to the compare list.

Timing Pulleys S8M

Timing Pulleys S8M

Timing Pulleys are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Belt Width Used (mm.) : 15 and 25

● Applicable with Belt Type : S8M

● Number of Teeth : 18, 19, 22, 24 and 25

● Shaft Bore Diameter Minimum/Maximum (mm.) : 12 to 30

● Shaft Bore Specs. : New JIS keyway + Tap

● Material : Aluminum Alloy

● Surface treatment : Clear Anodized

[Application]

Timing pulleys are frequently utilized in systems that incorporate timing belts to regulate and govern the movement of the machinery.From: ฿ 321.23 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

MISUMI

[Material]

· Pulley: Aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC, SUS304

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black iron oxide coating

[Related Products]

· Timing belt Timing Belt, Long Timing Belts-Iron Rubber, Open End Belt Iron Rubber, Open End Belts/Polyurethane/Chloroprene Rubber

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 4 Day(s)

4 Day(s)

-

Economy seriesYou can add up to 6 items per a category to the compare list.

Timing Pulleys HTD 8M

Timing Pulleys HTD 8M

Timing Pulleys are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Belt Width Used (mm.) : 20, 25, 30 and 40

● Applicable with Belt Type : 8M

● Number of Teeth Minimum/Maximum : 18 and 60

● Shaft Bore Diameter (mm.) : 8, 10, 12, 14 ,15 ,16 and 20

● Shaft Bore Specs. : Can select between Round Hole, Round Hole + Tap and New JIS keyway + Tap

● Material : Aluminum Alloy

● Surface treatment : Clear Anodized

[Application]

Timing pulleys are frequently utilized in systems that incorporate timing belts to regulate and govern the movement of the machinery.Days to Ship: 15 Day(s)

15 Day(s)

-

Economy seriesYou can add up to 6 items per a category to the compare list.

Timing Pulleys HTD 5M

Timing Pulleys HTD 5M

Timing Pulleys are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Belt Width Used (mm.) : 9 and 15

● Applicable with Belt Type : 5M

● Number of Teeth Minimum/Maximum : 14 and 32

● Shaft Bore Diameter (mm.) : 8, 10, 12, 14 ,15 ,16 and 20

● Shaft Bore Specs. : Can select between Round Hole + Tap and New JIS keyway + Tap

● Material : Aluminum Alloy

● Surface treatment : Clear Anodized

[Application]

Timing pulleys are frequently utilized in systems that incorporate timing belts to regulate and govern the movement of the machinery.From: ฿ 205.84 Days to Ship: Same day

Same day

-

Economy seriesYou can add up to 6 items per a category to the compare list.

Timing Pulleys T5

Timing Pulleys T5

Timing Pulleys are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Belt Width Used (mm.) : 10, 15, 20 and 25

● Applicable with Belt Type : T5

● Number of Teeth Minimum/Maximum : 12 to 26

● Shaft Bore Diameter Minimum/Maximum (mm.) : 5 to 15

● Shaft Bore Specs. : Can select between Round Hole + Tap and New JIS keyway + Tap

● Material : Aluminum Alloy

● Surface treatment : Clear Anodized

[Application]

Timing pulleys are frequently utilized in systems that incorporate timing belts to regulate and govern the movement of the machinery.From: ฿ 181.82 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

MISUMI

[Material]

· Pulley: Extra super duralumin aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC,

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black iron oxide coating

[Related Products]

· Timing belt Timing Belt, Long Timing Belts-Iron Rubber, Long Timing Belts-Polyurethane, Open End Belt Iron Rubber, Open End Belts/Polyurethane/Chloroprene Rubber

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

MISUMI

[Material]

· Pulley: Aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC, SUS304

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black iron oxide coating

[Related Products]

· Timing belt Timing Belt

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 4 Day(s)

4 Day(s)

-

Economy seriesYou can add up to 6 items per a category to the compare list.

Timing Pulleys XL

Timing Pulleys XL

Timing Pulleys are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Belt Width Used (mm.) : 6.4, 7.9, 9.5 and 12.7

● Belt Width Used (Inch.) : 0.25, 0.31, 0.37 and 0.5

● Applicable with Belt Type : XL

● Number of Teeth Minimum/Maximum : 10 to 50

● Shaft Bore Diameter Minimum/Maximum (mm.) : 5 to 16

● Shaft Bore Specs. : Can select between Round Hole, Round Hole + Tap and New JIS keyway + Tap

● Material : Aluminum Alloy

● Surface treatment : Clear Anodized

[Application]

Timing pulleys are frequently utilized in systems that incorporate timing belts to regulate and govern the movement of the machinery.From: ฿ 158.35 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

High Torque Timing Pulleys S2M Type

MISUMI

[Material]

· Pulley: A2000 aluminum alloy , S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC, SUS304

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black iron oxide coating

[Related Products]

· Timing belt High Torque Timing Belt

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

Timing Pulleys - AT5 / AT10 Type

MISUMI

[Material]

· Pulley: Aluminum alloy

· Flange: Aluminum alloy

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating

[Related Products]

· Timing belt Long Timing Belts-Iron Rubber, Long Timing Belts-Polyurethane, Open End Belt Iron RubberOpen End Belts/Polyurethane/Chloroprene Rubber

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 4 Day(s)

4 Day(s)

-

Economy seriesYou can add up to 6 items per a category to the compare list.

Timing Pulleys HTD 3M

Timing Pulleys HTD 3M

Timing Pulleys are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Belt Width Used (mm.) : 6, 9, and 12

● Applicable with Belt Type : 3M

● Number of Teeth Minimum/Maximum : 14 and 36

● Shaft Bore Diameter (mm.) : 5, 6, 6.35, 8 ,10 ,12 and 14

● Shaft Bore Specs. : Can select between Round Hole + Threaded hole and New JIS keyway + Tap

● Material : Aluminum Alloy

● Surface treatment : Clear Anodized

[Application]

Timing pulleys are frequently utilized in systems that incorporate timing belts to regulate and govern the movement of the machinery.From: ฿ 187.01 Days to Ship: Same day

Same day

-

Economy seriesYou can add up to 6 items per a category to the compare list.

Timing Pulleys S2M

Timing Pulleys S2M

Timing Pulleys are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Belt Width Used (mm.) : 4, 6 and 10

● Applicable with Belt Type : S2M

● Number of Teeth Minimum/Maximum : 16 to 40

● Shaft Bore Diameter (mm.) : 5, 6, 6.35, 8 and 12

● Shaft Bore Specs. : Can select between Round Hole, Round Hole + Tap and New JIS keyway + Tap

● Material : Aluminum Alloy

● Surface treatment : Clear Anodized

[Application]

Timing pulleys are frequently utilized in systems that incorporate timing belts to regulate and govern the movement of the machinery.From: ฿ 184.85 Days to Ship: Same day

Same day

-

You can add up to 6 items per a category to the compare list.

High Torque Timing Pulleys P5M Type

MISUMI

[Material]

· Pulley: Aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black oxide

[Related Products]

· Timing belt High Torque Timing Belt, Super High Torque Timing Belt, Open End Belts/Polyurethane/Chloroprene Rubber

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

MISUMI

[Material]

· Pulley: Extra super duralumin aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black iron oxide coating

[Related Products]

· Timing belt High Torque Timing Belt, Super High Torque Timing Belt, Long Timing Belts-Polyurethane, Open End Belts/Polyurethane/Chloroprene Rubber

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

High Torque Timing Pulleys - 1.5GT / 2GT Type

MISUMI

Since it has an arc tooth profile, it has little backlash and it is suitable for positioning applications.

[Material]

· Pulley: Aluminum alloy

· Flange: Aluminum alloy

[Surface treatment]

· Clear anodize

[Related Products]

· Timing belt High Torque Timing Belt,

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

High Torque Timing Pulleys P8M Type

MISUMI

[Material]

· Pulley: Extra super duralumin aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC

[Surface treatment]

· Clear anodize, black anodize, hard clear anodize (firm hardness 300HV~), electroless nickel plating, black oxide

[Related Products]

· Timing belt High Torque Timing Belt, Super High Torque Timing Belt, Open End Belts/Polyurethane/Chloroprene Rubber

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 5 Day(s)

5 Day(s)

-

You can add up to 6 items per a category to the compare list.

High Torque Timing Pulleys - 8YU

MISUMI

Since it has an arc tooth profile, it has little backlash and it is suitable for positioning applications.

[Material]

· Pulley: Aluminum alloy, S45C equivalent

· Flange: Aluminum alloy, SPCC

[Surface treatment]

· Clear anodize, black iron oxide coating

[Related Products]

· Timing belt High Torque Timing Belt,

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 5 Day(s)

5 Day(s)

-

Economy seriesYou can add up to 6 items per a category to the compare list.

Timing Pulleys MXL

Timing Pulleys MXL

Timing Pulleys are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Belt Width Used (mm.) : 4.8, 6.4 and 9.5

● Belt Width Used (Inch.) : 0.19, 0.25 and 0.37

● Applicable with Belt Type : MXL

● Number of Teeth Minimum/Maximum : 14 to 48

● Shaft Bore Diameter (mm.) : 4, 5, 6, 6.35 and 8

● Shaft Bore Specs. : Can select between Round Hole, Round Hole + Tap and New JIS keyway + Tap

● Material : Aluminum Alloy

● Surface treatment : Clear Anodized

[Application]

Timing pulleys are frequently utilized in systems that incorporate timing belts to regulate and govern the movement of the machinery.From: ฿ 289.14 Days to Ship: 6 Day(s)

6 Day(s)

-

You can add up to 6 items per a category to the compare list.

Timing Pulleys - Width Configurable - MXL, XL, S2M, S3M, S5M

MISUMI

This timing pulley can be specified the pulley width in units of 1 mm.

[Material]

· Pulley: Aluminum alloy

· Flange: Aluminum alloy

[Surface treatment]

· Clear anodize

[Pulley shape]

· A shape

[Shaft]

· Round hole, Round hole + TapDays to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

High Torque Timing Pulleys - 5GT Type

MISUMI

Since it has an arc tooth profile, it has little backlash and it is suitable for positioning applications.

[Material]

· Pulley: Aluminum alloy, S45C equivalent

· Flange: Aluminum alloy, SPCC

[Surface treatment]

· Clear anodize, black iron oxide coating

[Related Products]

· Timing belt High Torque Timing Belt,

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 4 Day(s)

4 Day(s)

-

You can add up to 6 items per a category to the compare list.

High Torque Timing Pulleys - 3GT Type

MISUMI

Since it has an arc tooth profile, it has little backlash and it is suitable for positioning applications.

[Material]

· Pulley: Aluminum alloy, S45C equivalent

· Flange: Aluminum alloy, SPCC

[Surface treatment]

· Clear anodize, black iron oxide coating

[Related Products]

· Timing belt High Torque Timing Belt,

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 6 Day(s)

6 Day(s)

-

You can add up to 6 items per a category to the compare list.

High Torque Timing Pulleys - S14M

MISUMI

[Material]

· Pulley: S45C equivalent

· Flange: S45C equivalent

[Surface treatment]

· Black oxide

[Related Products]

· Timing belt High Torque Timing Belt

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 9 Day(s)

9 Day(s)

-

You can add up to 6 items per a category to the compare list.

High Torque Timing Pulleys P2M/P3M Type

MISUMI

[Material]

· Pulley: High strength aluminum alloy, S45C equivalent, SUS304

· Flange: Aluminum alloy, SPCC

[Surface treatment]

· Clear anodize, electroless nickel plating, black iron oxide coating

[Related Products]

· Timing belt High Torque Timing Belt (P2M), High Torque Timing Belt (P3M)

· Idler Idler with Teeth Center Bearing, Idler with Teeth Both Sides Bearing, Idler - Backside Tensioning Center Bearing, Idler - Backside Tensioning Both Sides BearingDays to Ship: 5 Day(s)

5 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Specifications |

| Type |

| Belt Series |

| Belt Width Used (mm)(mm) |

| Number of Teeth(T) |

| Pulley Shape |

| Material |

| Belt Width Used(Inch)(Inch) |

| Surface Treatment |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | |||||||||||

| Product Series | Timing Pulleys - Width Configurable - MXL, XL, S2M, S3M, S5M | |||||||||||||||||||||||||||||||

| CAD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

| From | ฿ 191.68 | ฿ 281.83 | ฿ 185.63 | ฿ 321.23 | ฿ 205.84 | ฿ 181.82 | ฿ 158.35 | ฿ 187.01 | ฿ 184.85 | ฿ 289.14 | ||||||||||||||||||||||

| Days to Ship | Same day | Same day | 4 Day(s) | 4 Day(s) | 5 Day(s) | 4 Day(s) | Same day | 4 Day(s) | 5 Day(s) | Same day | 4 Day(s) | 15 Day(s) | Same day | Same day | 5 Day(s) | 4 Day(s) | Same day | 4 Day(s) | 4 Day(s) | Same day | Same day | 5 Day(s) | 5 Day(s) | 4 Day(s) | 5 Day(s) | 5 Day(s) | 6 Day(s) | 4 Day(s) | 4 Day(s) | 6 Day(s) | 9 Day(s) | 5 Day(s) |

| Specifications | ||||||||||||||||||||||||||||||||

| Type | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | - | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | - | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | - | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley | Timing Pulley |

| Belt Series | S5M | T10 | S5M | T5 | T10 | S8M | S3M | S3M | H | S8M | XL | 8M | 5M | T5 | L | MXL | XL | S2M | AT5 ~ AT10 | 3M | S2M | P5M | S8M | 1.5GT ~ 2GT | P8M | 8YU | MXL | S2M ~ XL | 5GT | 3GT | S14M | P2M ~ P3M |

| Belt Width Used (mm)(mm) | 10 ~ 25 | 15 ~ 50 | 10 ~ 25 | 10 ~ 25 | 15 ~ 50 | 15 ~ 40 | 6 ~ 15 | 6 ~ 15 | 19.1 ~ 76.2 | 15 ~ 40 | 6.4 ~ 19 | 20 ~ 40 | 9 ~ 15 | 10 ~ 25 | 12.7 ~ 38.1 | 4.8 ~ 12.7 | 6.4 ~ 12.7 | 4 ~ 10 | 10 ~ 25 | 6 ~ 12 | 4 ~ 10 | 10 ~ 15 | 15 ~ 40 | 4 ~ 9 | 15 ~ 25 | 15 ~ 25 | 6.4 | 4 ~ 25 | 9 ~ 15 | 6 ~ 15 | 40 ~ 74 | 6 ~ 15 |

| Number of Teeth(T) | 14 ~ 36 | 14 ~ 20 | 14 ~ 72 | 12 ~ 60 | 12 ~ 60 | 18 ~ 72 | 16 ~ 48 | 14 ~ 72 | 14 ~ 50 | 18 ~ 25 | 10 ~ 72 | 18 ~ 60 | 14 ~ 32 | 12 ~ 26 | 10 ~ 72 | 14 ~ 72 | 12 ~ 50 | 14 ~ 72 | 14 ~ 60 | 18 ~ 36 | 32 ~ 40 | 12 ~ 72 | 18 ~ 60 | 14 ~ 60 | 20 ~ 60 | 20 ~ 60 | - | 14 ~ 72 | 14 ~ 60 | 16 ~ 60 | 28 ~ 56 | 10 ~ 60 |

| Pulley Shape | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A | Shape A |

| Material | Aluminum | Aluminum | Steel / Aluminum / Stainless Steel | Steel / Aluminum | Steel / Aluminum | Steel / Aluminum | Aluminum | Steel / Aluminum / Stainless Steel | Steel / Aluminum | Aluminum | Steel / Aluminum / Stainless Steel | Aluminum | Aluminum | Aluminum | Steel / Aluminum | Steel / Aluminum / Stainless Steel | Aluminum | Steel / Aluminum / Stainless Steel | Aluminum | Aluminum | Aluminum | Steel / Aluminum | Steel / Aluminum | Aluminum | Steel / Aluminum | Steel / Aluminum | Aluminum | Aluminum | Steel / Aluminum | Steel / Aluminum | Steel | Steel / Aluminum |

| Belt Width Used(Inch)(Inch) | - | - | - | - | - | - | - | - | 0.75 ~ 2 | - | 0.25 ~ 0.5 | - | - | - | 0.5 ~ 1.5 | 0.19 ~ 0.5 | 0.25 ~ 0.5 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Surface Treatment | Clear Anodize | Clear Anodize | Not Provided / Black Oxide / Clear Anodize / Black Anodize / Hard Clear Anodize / Electroless Nickel Plating | Not Provided / Black Oxide / Clear Anodize / Black Anodize / Hard Clear Anodize / Electroless Nickel Plating | Not Provided / Black Oxide / Clear Anodize / Black Anodize / Hard Clear Anodize / Electroless Nickel Plating | Not Provided / Black Oxide / Clear Anodize / Black Anodize / Hard Clear Anodize / Electroless Nickel Plating | Clear Anodize | Not Provided / Black Oxide / Clear Anodize / Black Anodize / Hard Clear Anodize / Electroless Nickel Plating | Not Provided / Black Oxide / Clear Anodize / Black Anodize / Hard Clear Anodize / Electroless Nickel Plating | Clear Anodize | Not Provided / Black Oxide / Clear Anodize / Black Anodize / Hard Clear Anodize / Electroless Nickel Plating | Clear Anodize | Clear Anodize | Clear Anodize | Not Provided / Black Oxide / Clear Anodize / Black Anodize / Hard Clear Anodize / Electroless Nickel Plating | Not Provided / Black Oxide / Clear Anodize / Black Anodize / Hard Clear Anodize / Electroless Nickel Plating | Clear Anodize | Not Provided / Black Oxide / Clear Anodize / Black Anodize / Hard Clear Anodize / Electroless Nickel Plating | Clear Anodize / Black Anodize / Hard Clear Anodize / Electroless Nickel Plating | Clear Anodize | Clear Anodize | Black Oxide / Clear Anodize / Black Anodize / Hard Clear Anodize / Electroless Nickel Plating | Not Provided / Black Oxide / Clear Anodize / Hard Clear Anodize / Electroless Nickel Plating | Clear Anodize | Black Oxide / Clear Anodize / Hard Clear Anodize / Electroless Nickel Plating | Not Provided / Black Oxide / Clear Anodize | Clear Anodize | Clear Anodize | Not Provided / Black Oxide / Clear Anodize | Not Provided / Black Oxide / Clear Anodize | Not Provided / Black Oxide | Clear Anodize / Electroless Nickel Plating |

Loading...

Related Categories to Timing Pulleys, Idlers

FAQ Timing Pulley

- Question: What are pulleys used for?

- Answer: Pulleys designed for belt transmission facilitate the transfer of rotational motion and power among multiple shafts and belts, serving various industries. They enable speed and torque adjustment, change motion direction, guide the belt to maintain alignment and prevent slippage.

- Question: What benefits do pulleys offer?

- Answer: Pulleys offer several benefits in engineering applications:

1.Power transmission: They efficiently transfer rotational motion and power between shafts through the use of belts.

2. Speed and torque adjustment: Pulleys of different sizes allow engineers to adjust the speed and torque in belt drive systems, adapting them to specific requirements.

3. Belt tensioning: They help maintain proper belt tension, ensuring optimal power transfer and preventing slipping between the belt and pulleys.

4. Direction change: Pulleys enable the redirection of rotational motion, allowing for the driving of components located in different directions within a system.

5. Belt guidance and alignment: They guide the belt, keeping it aligned and preventing it from slipping off the pulley, ensuring reliable and smooth operation. - Question: Why are pulleys better than gears?

- Answer: 1.Simplicity installation : Pulleys have a simpler design and operation compared to gears. They consist of a grooved wheel and a belt, making them easier to install, and maintain. Gears, on the other hand, require precise tooth profiles and arrangements, adding complexity.

2.Noise and Vibration: Pulleys generally produce less noise and vibration compared to gears. The direct contact between gear teeth can create noise, particularly at high speeds. In contrast, pulleys that use a belt or rope for motion transfer offer smoother operation, resulting in reduced noise and vibration levels.

3.Misalignment Tolerance Available: Pulleys can accommodate a certain degree of misalignment between the driving and driven shafts. This flexibility is valuable in situations where precise alignment is challenging. Gears, on the other hand, require more precise alignment for optimal performance and can be sensitive to misalignment.

4.Overload Protection: Pulleys can provide some level of overload protection due to the slipping action of the belt. If the load exceeds a certain threshold, the belt may slip on the pulley, preventing damage to the system. Gears do not offer this slipping action and are more prone to damage when subjected to excessive loads.

It's important to recognize that gears have their own advantages, such as higher precision, greater efficiency, and the ability to transmit higher torque loads. The choice between pulleys and gears depends on the specific requirements of the application, including factors like load capacity, precision, speed control, and cost considerations. - Question: What are the 3 types of pulleys?

- Answer: 1. V-Belt Pulley: This type of pulley utilizes V-belts, which have a trapezoidal cross-section. V-belts fit into the grooves of the pulleys, creating friction and transmitting power. V-belt pulley transmissions are widely used in various applications, including automotive engines, industrial machinery, and HVAC systems.

2. Flat Belt Pulley: In a flat belt pulley a flat belt is used to transmit power between the pulleys. Flat belt pulley transmissions are often employed in agricultural machinery, textile mills, and other industrial applications.

3. Timing Belt Pulley: Timing belt pulley use toothed belts, known as timing belts, that have teeth on the inner surface. These teeth mesh with corresponding grooves on the pulleys, ensuring precise and synchronous power transmission. Timing belt pulley transmissions are commonly found in engines, camshaft drives, and other systems that require accurate timing. - Question: What are the advantages of a pulley?

- Answer: 1.Speed variation: Pulley power transmissions allow for speed variation by using pulleys of different sizes or adjusting the pulley ratio. This flexibility enables the adaptation of rotational speed to match specific operational requirements, providing optimal performance.

2.Directional flexibility: Pulleys provide the ability to change the direction of power transmission. This flexibility allows for versatile routing of power.

3.Quiet and smooth operation: Pulley power transmissions typically operate with minimal noise and vibration. The smooth transfer of power between pulleys results in quieter and more comfortable operation.

4.Cost-effectiveness: Pulley power transmissions are cost-effective due to their simplicity, and ease of installation. They require minimal maintenance, reducing overall machine system costs.

How can we improve?

How can we improve?