Electric Cylinder Radial Type E-ECRL5

Brand :

MISUMI

Caution

Product Description

This is an economy item, The price is cheaper than the MISUMI standard product.

Product Overview

An electric cylinder converts motor rotation into linear motion via a ball screw for push rod operatio.

Compared to hydraulic and pneumatic types, it offers energy efficiency, compact size, low noise, eco-friendliness, and low maintenance, reducing overall costs

MISUMI cylinders feature an aluminum alloy body, ball screw, push rod, customizable motor mounts, and optional sensors

The motor bracket's mounting hole size and position are processed according to the customer's specified motor brand.

A customized motor bracket and sensor switches are optional.

Compared to hydraulic and pneumatic types, it offers energy efficiency, compact size, low noise, eco-friendliness, and low maintenance, reducing overall costs

MISUMI cylinders feature an aluminum alloy body, ball screw, push rod, customizable motor mounts, and optional sensors

The motor bracket's mounting hole size and position are processed according to the customer's specified motor brand.

A customized motor bracket and sensor switches are optional.

Dimensional Drawing

| ■Motor Direct Connection BC | ■Motor Parallel Left Fold Connection BL | ■Motor Parallel Right Fold Connection BR | ■Motor Parallel Down Fold Connection BM |

|  |  |  |

| Body Width | 54×55 |

| Ball Screw | Φ12(C7) |

| Positioning Repeatability | ±0.01 |

| Components | Main Body | Built-in Linear Guide | Slide Block | Push Rod | Motor Bracket |

Material Material | Aluminum Alloy | Stainless Steel | Aluminum Alloy | S45C | Aluminum Alloy |

Surface Treatment Surface Treatment | Clear Anodized | - | Clear Anodized | Chrome Plating | Clear Anodized |

| E-ECRL5 Stroke S | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | |

| L | Direct connection | 319 | 369 | 419 | 469 | 519 | 569 | 619 | 669 | 719 | 769 | 819 | 869 |

| Parallel connection | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | |

| Mounting Dimension | A | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 |

| Number of Pitch※ | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | |

| Number of Hole N※ | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | |

| Main Body Mass(kg) | Direct connection | 1.71 | 1.98 | 2.24 | 2.50 | 2.77 | 3.03 | 3.30 | 3.56 | 3.82 | 4.09 | 4.35 | 4.61 |

| Parallel connection | 1.99 | 2.25 | 2.52 | 2.78 | 3.04 | 3.30 | 3.56 | 3.83 | 4.09 | 4.35 | 4.61 | 4.87 | |

Please follow the selection steps ~

~ select the model and parameters to order.

select the model and parameters to order.

※1 Max speed is based on a 3000 rpm servo motor; reduce speed if stroke >300 to prevent resonance.

Motor not included; customers must purchase separately. When the motor code is specified as Z, the motor shaft diameter and installation dimensions must be provided.

Motor not included; customers must purchase separately. When the motor code is specified as Z, the motor shaft diameter and installation dimensions must be provided.

Motor acceleration and deceleration time is recommended to be set at 0.2 second

Motor acceleration and deceleration time is recommended to be set at 0.2 second

■Recommended servo motor list

■Components

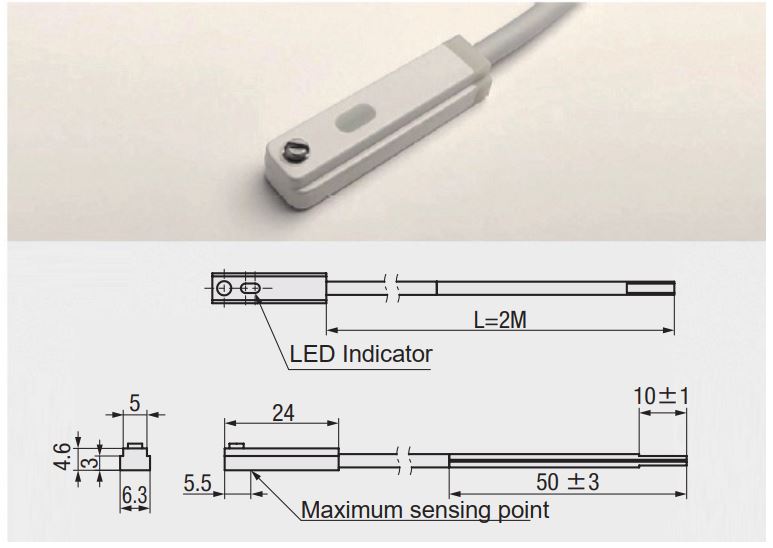

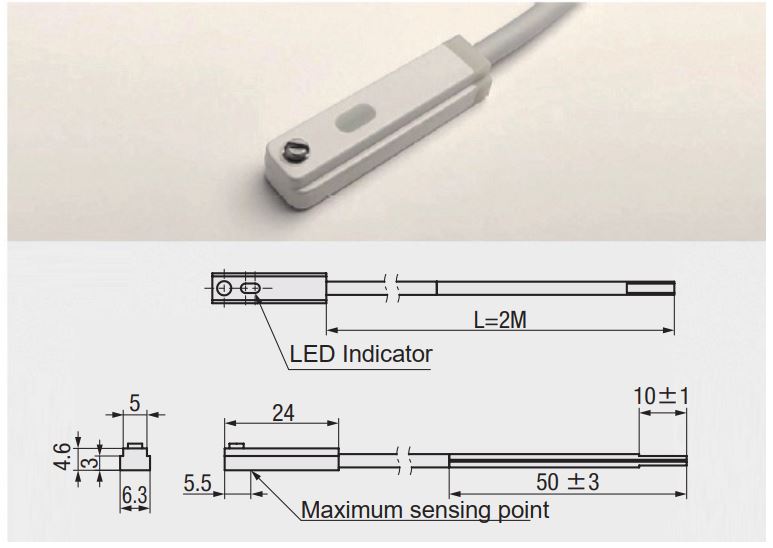

■E-ECRL Sensor Specification

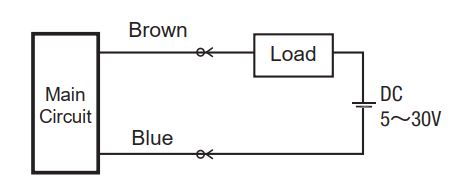

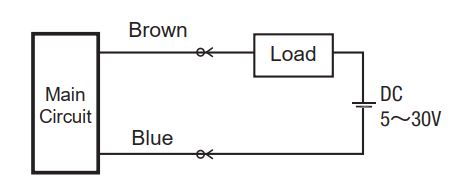

■Sensor Wiring Diagram

■Sensor parameters

~

~ select the model and parameters to order.

select the model and parameters to order.Specification Table

| Model( Type) Type) | - |  Lead Lead | - |  Strock S Strock S | - |  Motor Direction Motor Direction | - |  Motor Type Motor Type | - |  Number of Sensor Number of Sensor | |

| E-ECRL5 | - | 05 | - | S100 | - | BM | - | P100W | - | C0 |

| Model |  StrokeS StrokeS |  Motor Direction Motor Direction |  Motor Type Motor Type |  Number of Number ofSensor | Rated Thrust (N) | Max Speed (mm/s)※1 | Max. Payload(kg) | Positioning Repeatability (mm) | Body Width | Ball Screw | |||

Type Type |  Lead Lead(mm) | 50mm Increment | Brand | Power W | Horizontal | Vertical | |||||||

| E-ECRL5 | 05 | 50~600 | BC(Direct connection) BM(Parallel Left Fold) BL(Parallel Right Fold) BR(Parallel Down Fold) | P(Panasonic) M(Motor table) Z(Customized) | 100W | C0(Not Provided) C1(1pc) C2(2pcs) C3(3pcs) | 340 | 250 | 30 | 10 | ±0.01 | 54×55 | Φ12 (C7) |

| 10 | 170 | 500 | 15 | 5 | |||||||||

| 20 | 85 | 1000 | 10 | 2.5 | |||||||||

Motor not included; customers must purchase separately. When the motor code is specified as Z, the motor shaft diameter and installation dimensions must be provided.

Motor not included; customers must purchase separately. When the motor code is specified as Z, the motor shaft diameter and installation dimensions must be provided. Motor acceleration and deceleration time is recommended to be set at 0.2 second

Motor acceleration and deceleration time is recommended to be set at 0.2 second■Motor Code and Brand

| Code | Brand | |

| P | Panasonic | |

| M | Mitsubishi / Yaskawa / Delta / Siemens Inovance / Xinjie / Leadshine / Omron / HCFA | |

| Z | Customized | |

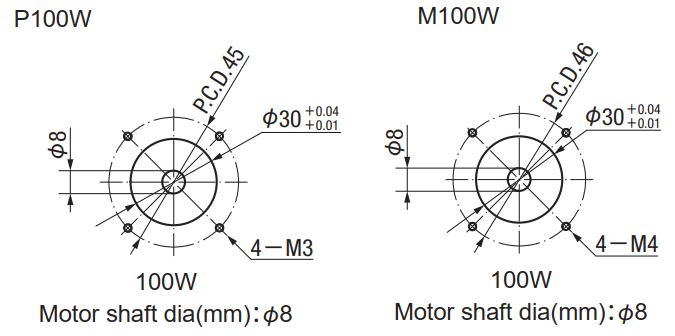

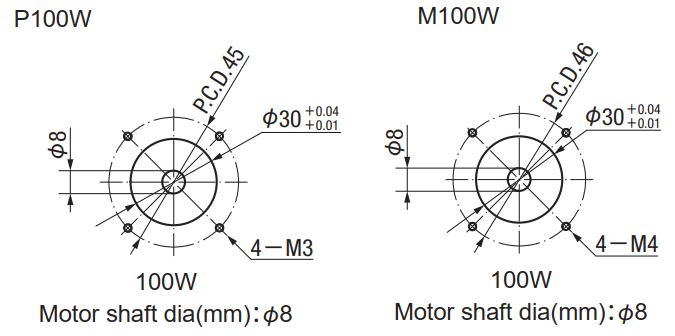

■Motor Mounting Hole Dimension

■Recommended servo motor list

| Brand | Motor code | With / Without Brake | Power | Voltage | Servo Motor Model | Driver Model |

| Panasonic | P | Without Brake (Horizontal Use) | 50W | 220V | MSMF5AZL1U2M | MADLN05SE |

| With Brake (Vertical Use) | MSMF5AZL1V2M | |||||

| Without Brake (Horizontal Use) | 100W | MSMF012L1U2M | MADLN05SE | |||

| With Brake (Vertical Use) | MSMF012L1V2M | |||||

| Without Brake (Horizontal Use) | 200W | MHMF022L1U2M | MADLN15SE | |||

| With Brake (Vertical Use) | MHMF022L1V2M | |||||

| Without Brake (Horizontal Use) | 400W | MHMF042L1U2M | MBDLN25SE | |||

| With Brake (Vertical Use) | MHMF042L1V2M | |||||

| Without Brake (Horizontal Use) | 750W | MHMF082L1U2M | MCDLN35SE | |||

| With Brake (Vertical Use) | MHMF082L1V2M | |||||

| Without Brake (Horizontal Use) | 1000W | MDMF102L1G6M | MDDLN45SE | |||

| With Brake (Vertical Use) | MDMF102L1H6M | |||||

| Without Brake (Horizontal Use) | 1500W | MDMF152L1G6 | MDDLN55SE | |||

| With Brake (Vertical Use) | MDMF152L1H6 | |||||

| Without Brake (Horizontal Use) | 2000W | MDMF202L1G6 | MEDLN83SE | |||

| With Brake (Vertical Use) | MDMF202L1H6 | |||||

| Mitsubishi | M | Without Brake (Horizontal Use) | 50W | 220V | HG-MR053 | MR-J4-10A |

| With Brake (Vertical Use) | HG-MR053B | |||||

| Without Brake (Horizontal Use) | 100W | HG-KR13 | MR-J4-10A | |||

| With Brake (Vertical Use) | HG-KR13B | |||||

| Without Brake (Horizontal Use) | 200W | HG-KR23 | MR-J4-20A | |||

| With Brake (Vertical Use) | HG-KR23B | |||||

| Without Brake (Horizontal Use) | 400W | HG-KR43 | MR-J4-40A | |||

| With Brake (Vertical Use) | HG-KR43B | |||||

| Without Brake (Horizontal Use) | 750W | HG-KR73 | MR-J4-70A | |||

| With Brake (Vertical Use) | HG-KR73B | |||||

| Without Brake (Horizontal Use) | 1000W | HG-SR102 | MR-J4-100A | |||

| With Brake (Vertical Use) | HG-SR102B | |||||

| Without Brake (Horizontal Use) | 1500W | HG-SR152 | MR-J4-200A | |||

| With Brake (Vertical Use) | HG-SR152B | |||||

| Yaskawa | M | Without Brake (Horizontal Use) | 50W | 220V | SGM7J-01AFC6S | SGD7S-R90A00A002 |

| With Brake (Vertical Use) | SGM7J-01AFC6E | |||||

| Without Brake (Horizontal Use) | 100W | SGM7J-01AFC6S | SGD7S-R90A00A002 | |||

| With Brake (Vertical Use) | SGM7J-01AFC6E | |||||

| Without Brake (Horizontal Use) | 200W | SGM7J-02AFC6S | SGD7S-1R6A00A002 | |||

| With Brake (Vertical Use) | SGM7J-02AFC6E | |||||

| Without Brake (Horizontal Use) | 400W | SGM7J-04AFC6S | SGD7S-2R8A00A002 | |||

| With Brake (Vertical Use) | SGM7J-04AFC6E | |||||

| Without Brake (Horizontal Use) | 750W | SGM7J-08AFC6S | SGD7S-5R5A00B202 | |||

| With Brake (Vertical Use) | SGM7J-08AFC6E | |||||

| Delta | M | Without Brake (Horizontal Use) | 100W | 220V | ECM-B3L-C20401RS1 | ASD-B3-0121-L |

| With Brake (Vertical Use) | ECM-B3L-C20401SS1 | |||||

| Without Brake (Horizontal Use) | 200W | ECM-B3M-C20602RS1 | ASD-B3-0221-L | |||

| With Brake (Vertical Use) | ECM-B3M-C20602SS1 | |||||

| Without Brake (Horizontal Use) | 400W | ECM-B3M-C20604RS1 | ASD-B3-0421-L | |||

| With Brake (Vertical Use) | ECM-B3M-C20604SS1 | |||||

| Without Brake (Horizontal Use) | 750W | ECM-B3M-C20807RS1 | ASD-B3-0721-L | |||

| With Brake (Vertical Use) | ECM-B3M-C20807SS1 | |||||

| P | Without Brake (Horizontal Use) | 1000W | ECM-B3M-E21310RS1 | ASD-B3-0121-L | ||

| With Brake (Vertical Use) | ECM-B3M-E21310SS1 | |||||

| Without Brake (Horizontal Use) | 1500W | ECM-B3M-E21315RS1 | ASD-B3-1521-L | |||

| With Brake (Vertical Use) | ECM-B3M-E21315SS1 | |||||

| Without Brake (Horizontal Use) | 2000W | ECM-B3M-E21320RS1 | ASD-B3-2023-L | |||

| With Brake (Vertical Use) | ECM-B3M-E21320SS1 |

■Components

| Component name | Type | 100W | |||

| Direct connection | Coupling | Disk Coupling Clamp Type | Outside diameter | Ball screw side | Motor side |

| Φ26 | Φ7 | Φ8 | |||

| Parallel connection | Ball screw pulley | Nickel Plating Steel | 2GT-40Teeth×Φ7 | ||

| Motor pulley | 2GT-40Teeth×Φ8 | ||||

| Timing belt | Glass fiber core rubber | 220-2GT-12 | |||

| Sensor (Optional) | DMSE-020-2M (DC 2-wire, Normal open) | ||||

■E-ECRL Sensor Specification

■Sensor Wiring Diagram

■Sensor parameters

| Mode | Output Type | Install Method | Detection Method | Working Voltage | Current Consumption | Output Current | Repeatability | Switching Frequency | Indicator Light | Working Environment Temperature | Cable Length | Protection Rating |

| DMST DMSE | DC 2-wire, Normal open | Screw clamp to cylinder groove | Magnet ring | 5~30V DC | ≦0.05mA | ≦100mA | <0.2㎜ | ≦2000Hz | Red light | -20~+70℃ | 2m | IP67 |

Product Features

■Structure

■Advantages

・Repeat positioning accuracy ±0.01mm

・Primarily used for horizontal installation. Its built-in linear guide and ball slider help withstand radial loads and prevent output shaft rotation.

・Besides standard functions, it is more suitable for applications with longer strokes.

■Advantages

・Repeat positioning accuracy ±0.01mm

・Primarily used for horizontal installation. Its built-in linear guide and ball slider help withstand radial loads and prevent output shaft rotation.

・Besides standard functions, it is more suitable for applications with longer strokes.

| Main Body Installation |

| |||||||||||||

| ||||||||||||||

| Front-End Installation | Rear-End Installation (Parallel Type Only) | |||||||||||||

|  | |||||||||||||

Precautions

■Precautions for Use

①Operating environment: Room temperature (-20℃ to 40℃). Avoid corrosive, flammable, electromagnetic, or moist environments.

②Ensure the installation surface is vibration and pressure-resistant, with flatness within ±0.05mm/500mm.

③Use a motor with a brake when the electric cylinder is mounted vertically.

④Protect the cylinder from vibration and impact. Prevent the push rod from rotating and the cylinder from deforming.

①Operating environment: Room temperature (-20℃ to 40℃). Avoid corrosive, flammable, electromagnetic, or moist environments.

②Ensure the installation surface is vibration and pressure-resistant, with flatness within ±0.05mm/500mm.

③Use a motor with a brake when the electric cylinder is mounted vertically.

④Protect the cylinder from vibration and impact. Prevent the push rod from rotating and the cylinder from deforming.

Usage Method

| 【Parallel Electric Cylinder Timing Pulley and Belt Installation Method】 | 【Magnetic Switch Installation Method】 | 【Return-to-Origin Speed Setting Method】 |

■Motor Installation and Timing Belt Tension Adjustment Method

Radial Type Direct Connection E-ECRL

1) Remove the plastic cover and loosen the bolts on the coupling

2) Install the motor and tighten the bolts.

3) Finally, reattach the plastic cover on the coupling seat to complete the motor installation.

Radial Type Parrallel Connection E-ECRL

1) Remove the cover, install the motor, and tighten the screws.

2) Install the timing pulley on the motor side, ensuring it is parallel to the pulley on the ball screw end, and tighten the pulley screws.

3) Fit the timing belt and ensure the tension bearing is positioned above the belt (E-ECRL5/8)

4) Adjust belt tension with the adjustment screw and secure with fastening screws.

5) Measure belt tension with a tester to match the reference range (see table).

6) Reattach the cover to finish motor installation and pulley adjustment.

Electric cylinder belt tension value (reference)

Radial Type Direct Connection E-ECRL

1) Remove the plastic cover and loosen the bolts on the coupling

2) Install the motor and tighten the bolts.

3) Finally, reattach the plastic cover on the coupling seat to complete the motor installation.

Radial Type Parrallel Connection E-ECRL

1) Remove the cover, install the motor, and tighten the screws.

2) Install the timing pulley on the motor side, ensuring it is parallel to the pulley on the ball screw end, and tighten the pulley screws.

3) Fit the timing belt and ensure the tension bearing is positioned above the belt (E-ECRL5/8)

4) Adjust belt tension with the adjustment screw and secure with fastening screws.

5) Measure belt tension with a tester to match the reference range (see table).

6) Reattach the cover to finish motor installation and pulley adjustment.

Electric cylinder belt tension value (reference)

| Motor Power W | Electric Cylinder Mode | Timing Belt Type | Belt Width (mm) | Pulley Center Distance (mm) | Belt Thickness (M) | Tension Value (N) (Reference) |

| 100W | E-ECTL40/E-ECRL5 | 2GT | 12 | 55 | 1.3 | 12~17 |

| 200W | E-ECTL50/E-ECRL8 | 3GT | 15 | 81 | 2.5 | 32~42 |

| 400W | E-ECTL60/E-ECRL8 | |||||

| E-ECTLT60 | 5GT | 75 | 4 | 60~75 | ||

| 750W | E-ECTL75/E-ECRL10 | 107 | ||||

| E-ECTLT75 | 8YU | 25 | 104 | 5.2 | 125~155 | |

| 1000W | E-ECTL90/E-ECTLT90 | 8M | 30 | 128 | 6.1 | 409~450 |

| 1500W | ||||||

| 2000W | E-ECTL90 | |||||

| E-ECTLT110 | 50 | 160 | 573~630 |

Example of Use

■Radial Load Electric Cylinder Usage Example

Application: Sorting Mechanism

・Use the cylinder's push-pull function to sort items by height on the same conveyor

・The cylinder-based sorting mechanism ensures fast and smooth

Application: Sorting Mechanism

・Use the cylinder's push-pull function to sort items by height on the same conveyor

・The cylinder-based sorting mechanism ensures fast and smooth

Application Industry

| Electronic | Smartphone | Lithium battery | ||

|  |  | ||

| Automotive | Robotics | Medical | ||

|  |  |

Related Documents

■Regular Lubrication Method

・The Electric Cylinder requires regular lubrication. Initially, add grease after 300 hours of operation. Subsequently, lubricate every 2000 hours.

・Use general lithium-based grease for lubrication. Mobil lithium grease EP3 is recommended.

・Use a grease gun for lubrication. Do not use liquid lubricants.

1)Open the cylinder cover and apply oil to the bearings in the motor mount and the sliding table

2)Manually move the sliding table and apply oil every 15mm along the stroke direction

・The Electric Cylinder requires regular lubrication. Initially, add grease after 300 hours of operation. Subsequently, lubricate every 2000 hours.

・Use general lithium-based grease for lubrication. Mobil lithium grease EP3 is recommended.

・Use a grease gun for lubrication. Do not use liquid lubricants.

1)Open the cylinder cover and apply oil to the bearings in the motor mount and the sliding table

2)Manually move the sliding table and apply oil every 15mm along the stroke direction

Related Products

| Single Axis Robots, Guide Built in Type | Single Axis Actuators KS series | Electric Cylinder, Standard type | ||

|  |  | ||

| Representative Part number: E-MGT5-L10-100-BC-P10-C | Representative Part number:C-KS4001-B1-100-F1-W2 | Representative Part number: E-ECTL40-10-S100-BC-P100W |