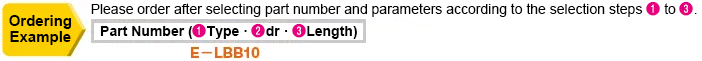

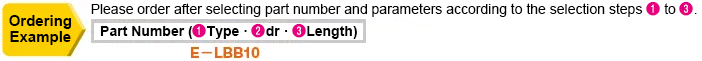

Ball Bushings Straight

Caution

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part02 CLICK here

Product Description

Bushings are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Inner Diameter Minimum/Maximum (mm.) : 5 and 50

● Overall Length Minimum/Maximum (mm.) : 15 and 100

● Operating Temperature (℃) : -20 to 110

● Material

Housing and Ball - SUJ2 Equivalent

Retainer - 6063T5

[Application]

Bushings are commonly used in various applications in factory automation systems

Product Overview of Linear Bushings

Product Features of Linear Bushings

Feature of Linear Bushings 1: Effective utilization of space. The combination of the guide shaft and the linear bushing enables effective use of space, suitable for small mechanism designs.

Feature of Linear Bushings 2: Good interchangeability. Linear bushings have good interchangeability because they can be used with shafts randomly.

Feature of Linear Bushings 3: Appropriate specifications can be selected according to the conditions of use.

Feature of Linear Bushings 4: More cost effective than the linear guide.

Dimensional Drawing of Linear Bushings

| Case | Ball | Retainer | Ambient Operating Temp | ||

Material of Linear Bushings Material of Linear Bushings |  Hardness Hardness |  Surface Treatment Surface Treatment |  Material Material |  Material Material | |

| Equivalent to SUJ2 | 58HRC~ | Electroless Nickel Plating | Equivalent to SUJ2 | 6063T5 | -20~110℃ |

Specification Table of Linear Bushings

| Part Number of Linear Bushings | Max. Stroke | Rows of balls | D | L | R | B | W | D1 | |||||||||

Type Type |  dr dr | Tolerance |  Length Length | Single | Double | Single | Double | Tolerance Range | Tolerance Range | Single | Double | Tolerance Range | |||||

| E-LBB | 5 | 0 -0.009 | Not Specified (Single Type) L (Double Type) | 16 | 7 | 3 | 6 | 10 | 0 -0.016 | 15 | ±0.2 | 5 | 10 | 8 | 0 -0.5 | 1.1 | 9.6 |

| 6 | 20 | 7.2 | 12 | 19 | 6.2 | 12.4 | 11.3 | 11.5 | |||||||||

| 8 | 24 | 8.5 | 15 | 24 | 8 | 16 | 15.3 | 14.3 | |||||||||

| 10 | 33 | 14 | 19 | 0 -0.019 | 29 | 9 | 18 | 19.4 | 1.3 | 18 | |||||||

| 12 | 34 | 17 | 21 | 30 | 10 | 20 | 20.4 | 20 | |||||||||

| 13 | 36 | 23 | 32 | 22 | |||||||||||||

| 16 | 40 | 18 | 4 | 8 | 28 | 37 | 13 | 26 | 23.3 | 1.6 | 27 | ||||||

| 20 | 0 -0.010 | 47 | 22 | 32 | 0 -0.022 | 42 | 14 | 28 | 27.3 | 30.5 | |||||||

| 25 | 50 | 37 | 45 | 15 | 30 | 28.3 | 35.3 | ||||||||||

| 30 | 85 | 47 | 3 | 6 | 45 | 64 | 18 | 36 | 40.8 | 1.85 | 43 | ||||||

| 35 | 0 -0.012 | 90 | 55 | 52 | 0 -0.03 | 70 | ±0.3 | 20 | 40 | 45.3 | 2.1 | 49 | |||||

| 40 | 110 | 69 | 60 | 80 | 56.3 | 57 | |||||||||||

| 45 | 65 | 24 | 48 | 2.15 | 62 | ||||||||||||

| 50 | 140 | 89 | 72 | 100 | 72.3 | 2.65 | 70 | ||||||||||

Unlike Linear Bushings, a non-circulating ball mechanism is used, so the stroke is limited. Please be sure to use it within the maximum stroke.

Unlike Linear Bushings, a non-circulating ball mechanism is used, so the stroke is limited. Please be sure to use it within the maximum stroke.

| Part Number | Max. Stroke | Rows of balls | D | L | R | B | W | D1 | |||||||||

Type Type |  dr dr | Tolerance |  Length Length | Single | Double | Single | Double | Tolerance Range | Tolerance Range | Single | Double | Tolerance Range | |||||

| E-LBB | 5 | 0 -0.009 | Not Specified (Single Type) L (Double Type) | 16 | 7 | 3 | 6 | 10 | 0 -0.016 | 15 | ±0.2 | 5 | 10 | 8 | 0 -0.5 | 1.1 | 9.6 |

| 6 | 20 | 7.2 | 12 | 19 | 6.2 | 12.4 | 11.3 | 11.5 | |||||||||

| 8 | 24 | 8.5 | 15 | 24 | 8 | 16 | 15.3 | 14.3 | |||||||||

| 10 | 33 | 14 | 19 | 0 -0.019 | 29 | 9 | 18 | 19.4 | 1.3 | 18 | |||||||

| 12 | 34 | 17 | 21 | 30 | 10 | 20 | 20.4 | 20 | |||||||||

| 13 | 36 | 23 | 32 | 22 | |||||||||||||

| 16 | 40 | 18 | 4 | 8 | 28 | 37 | 13 | 26 | 23.3 | 1.6 | 27 | ||||||

| 20 | 0 -0.010 | 47 | 22 | 32 | 0 -0.022 | 42 | 14 | 28 | 27.3 | 30.5 | |||||||

| 25 | 50 | 40 | 59 | 15 | 30 | 28.3 | 35.3 | ||||||||||

| 30 | 85 | 47 | 3 | 6 | 45 | 64 | 18 | 36 | 40.8 | 1.85 | 43 | ||||||

| 35 | 0 -0.012 | 90 | 55 | 52 | 0 -0.03 | 70 | ±0.3 | 20 | 40 | 45.3 | 2.1 | 49 | |||||

| 40 | 110 | 69 | 60 | 80 | 56.3 | 57 | |||||||||||

| 45 | 65 | 24 | 48 | 2.15 | 62 | ||||||||||||

| 50 | 140 | 89 | 72 | 100 | 72.3 | 2.65 | 70 | ||||||||||

Unlike linear bushings, a non-circulating ball mechanism is used, so the stroke is limited. Please be sure to use it within the maximum stroke.

Unlike linear bushings, a non-circulating ball mechanism is used, so the stroke is limited. Please be sure to use it within the maximum stroke.| Basic Load Rating | ||||

| C (Dynamic) N | Co (Static) N | |||

| dr | Single | Double | Single | Double |

| 5 | 118 | 160 | 102 | 146 |

| 6 | 232 | 380 | 160 | 320 |

| 8 | 358 | 590 | 262 | 520 |

| 10 | 656 | 1140 | 490 | 1030 |

| 12 | 1120 | 1810 | 850 | 1720 |

| 13 | 1180 | 1830 | 880 | 1750 |

| 16 | 1590 | 2230 | 1660 | 2360 |

| 20 | 1640 | 2310 | 1730 | 2520 |

| 25 | 1710 | 2420 | 1360 | 2780 |

| 30 | 3120 | 4920 | 3220 | 6710 |

| 35 | 3260 | 5180 | 3610 | 7200 |

| 40 | 4380 | 6930 | 4960 | 9810 |

| 45 | 4420 | 7060 | 5120 | 9960 |

| 50 | 5810 | 9210 | 7130 | 14300 |

| Case | Ball | Retainer | Ambient Operating Temp | ||

Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment |  Material Material |  Material Material | |

| Equivalent to SUJ2 | 58HRC~ | Electroless Nickel Plating | Equivalent to SUJ2 | 6063T5 | -20~110℃ |

① Before use, please apply grease to the ball row inside the linear bushing, and then replenish it in due course. Grease forms an oil film on the surfaces of steel ball and rolling surface (guide shaft·bushing) of linear bushing, which effectively reduces friction and prevents sintering. Grease reduction and aging will greatly affect the life of linear bushing.

② Recommended grease: lithium soap grease. Click

Grease

Greasefor details. ③ Recommended grease filling interval: Usually every 6 months.

④When the moving distance is long, it is recommended to move once every three months or when the moving distance exceeds 1000km within the time limit, the 1000km shall prevail.

⑤ When the linear bushing is subjected to large moment load (eccentric load), one piece of single type is not applicable, so it is recommended to use one piece of double type or multiple pieces of single type.

■ Dust prevention measures:

If dust or foreign matter enters the inside of the linear bushing, it may damage the circulation of steel balls, resulting in unexpected failures. When used in harsh environment, please install dust cover and protection cover, etc.

■ MISUMI linear bushing is recommended to be installed on the holder with H7 tolerance. The linear bushing is in clearance fit with the housing.

■Unlike linear bushings, a non-circulating ball mechanism is used, so the stroke is limited. Please be sure to use it within the maximum stroke.

■For preloaded use, it is recommended to use a MISUMI quenched guide shaft with an outer diameter tolerance of h5.

■ MISUMI linear bushing is recommended to be combined with guide shaft with quenching g6 tolerance.

Usage Method.

Usage Method.For anti-rust performance and maintenance of metal materials and their surface treatment, please refer to

Anti-rust Performance.

Anti-rust Performance.

*Economy series products are more suitable for medium precision linear motion and rotary motion than standard products

| Electronic & Electrical | Automotive | Lithium battery | ||

|  |  | ||

| LCD | Smart Phones | Semiconductor | ||

|  |  |