XY-Axis Motorized Positioning Stages, Linear Ball Guide Type, Positioning Repeatability ±5μ

Caution

- Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

・ Product Type: XY-Axis Motorized Positioning Stages, C-XYMBS series.

・ Table size [mm]: 40x40, 60x60, 60x100, 80x80

・ Table movement stroke [mm]: 18, 28, 43, 20

・ Cable length [m]: 2, 4

・ Movement structure: Ball Screw Φ6, Lead 1mm with Linear Ball Guide.

・ Maximum movement speed: 10 mm/sec

・ One-Way Positioning Accuracy: Within 20μm

・ Repetitive Positioning Accuracy: Within ±5.0μm

・ This is an economy item; The price is cheaper than the MISUMI standard product.

The above diagram shows the situation when cover plate L is selected. For detailed dimensions when selecting cover plate R, please refer to the CAD data.

The above diagram shows the situation when cover plate L is selected. For detailed dimensions when selecting cover plate R, please refer to the CAD data. In the above diagram, when the 820 cover plate is type L, the upper shaft is type L and the lower shaft is type R. When the 820 cover plate is type R, the upper shaft is type R and the lower shaft is type L.

In the above diagram, when the 820 cover plate is type L, the upper shaft is type L and the lower shaft is type R. When the 820 cover plate is type R, the upper shaft is type R and the lower shaft is type L. The length of the motor-side connector cable varies depending on the model. Please refer to the actual product for details.

The length of the motor-side connector cable varies depending on the model. Please refer to the actual product for details. The purchased model includes the slide table body, corresponding driver, and cable. No additional purchase is necessary.

The purchased model includes the slide table body, corresponding driver, and cable. No additional purchase is necessary.C-XYMBS□□□-R-S3

Material Material |  Surface treatment Surface treatment |  Accessories Accessories |

| Alloy steel | Electroless nickel plating | Positioning pins Quantity: 4 |

| Type | Slide Table Length (mm) |  Cover Plate Position Cover Plate Position |  Motor Motor |  Driver Driver |  Cable Length (m) Cable Length (m) | Mechanical Specifications | ||||

Type Type |  Type Type | Travel distance (mm) | Load capacity (N) | Weight (kg) | ||||||

| C-XYMBS | XY axis | 420 | 40 × 40 | L | Blank (with standard stepper motor) S3 (with 28-frame stepper motor mounting bracket) | A (single-axis pulse driver) N (without driver) E (EtherCat bus driver) | 2 4 | 18 | 94 | 0.8 |

| R | ||||||||||

| 630 | 60 × 60 | L | 28 | 92 | 1.2 | |||||

| R | ||||||||||

| 650 | 60 × 100 | L | 43 | 90 | 1.6 | |||||

| R | ||||||||||

| 820 | 80 × 80 | L | 20 | 109.0 | 2.2 | |||||

| R | ||||||||||

| Type | Accuracy specifications*1 | Sensor | ||||||||

| Resolution (pulses) | Maximum speed | Unidirectional positioning accuracy | Repeat positioning accuracy | Non-effective movement | Parallelism | Motion straightness | Motion parallelism | Limit sensor | Origin sensor (ORG1) | |

| 420 | 5 µm | 10 mm/sec | Within 20 µm | Within ±5.0 µm | 10µm | 30 µm | 10µm | 20µm | Yes | Yes |

| 630 | ||||||||||

| 650 | ||||||||||

| 820 | ||||||||||

Driver: The driver model used in this series is E-DR42B.

Driver: The driver model used in this series is E-DR42B. Bus driver brand and model: Leadshine DM3C-EC522.

Bus driver brand and model: Leadshine DM3C-EC522. Cable: The cable models used in this series are HRS12-2M (2-meter cable) / HRS12-4M (4-meter cable).

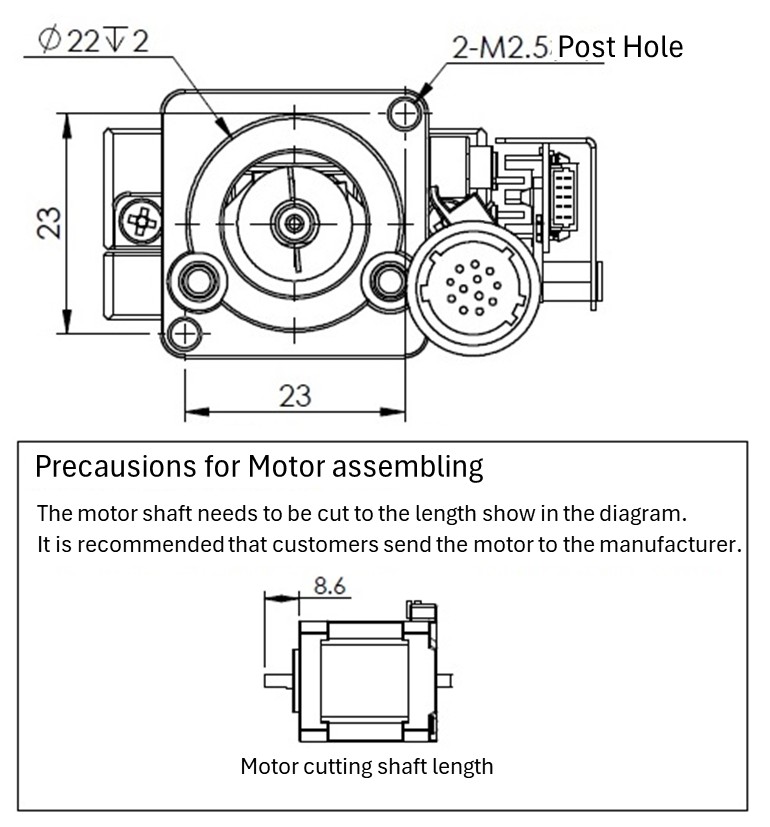

Cable: The cable models used in this series are HRS12-2M (2-meter cable) / HRS12-4M (4-meter cable). Servo motor mounting bracket type. Recommended motor brands: Yaskawa, Inovance, Mitsubishi, Leadshine, Moons, etc. Recommended power: 50W, 100W. Please carefully check the motor mounting dimensions.

Servo motor mounting bracket type. Recommended motor brands: Yaskawa, Inovance, Mitsubishi, Leadshine, Moons, etc. Recommended power: 50W, 100W. Please carefully check the motor mounting dimensions.■ General specifications

| Feed screw | Ball screw ⌀6, lead 1 mm | |

| Motor | Type | 2-phase stepper motor |

| Step angle | 1.8° | |

| Driver | Power supply voltage | DC12 to 50 V |

| Output current | 0.1 to 2.2 A | |

| Pulse signal voltage | 5 to 24 V | |

| Pulse input mode | Dual pulse / pulse + direction | |

| Microstep settings | 200 to 51200 | |

| Connector | Type | HR10A-10J-12P (Hirose) |

| Receiver side type | HR10A-10P-12S (Hirose) | |

| Sensor board | Power supply voltage | 24 V DC ±10% |

| Sensor type | Miniature photoelectric sensor EE-SX4320 (Omron) | |

| Control output | NPN open collector output | |

| Output logic | When detected (light blocked): output transistor OFF (not conducting) | |

■ Wiring diagram

t1 < 0.1 µs t2 ≥ 0.9 µs t3 ≥ 10 µs

t4: ENA (enable signal) t4 should be set high at least 10 µs before DIR. In general, it is recommended to leave ENA+ and ENA- unconnected.

Feature 2: By rearranging the internal steel balls and extending the base, selectable travel ranges from 18 mm to 43 mm are available.

Feature 3: By adding positioning holes to the upper and lower bases of the slide table, quick assembly and disassembly are achieved.

Feature 4: The 40/60/80 series positioning hole diameters and positions are standardized, allowing slide tables of different sizes to be combined, offering diverse combinations.

Feature 5: The voltage for limit sensors/drivers has been increased to 32 V, reducing failures such as burnout caused by unstable voltage.

Indicates the distance the slide table surface can move. (In each product page, the illustration is shown at the center position of the travel range.)

■ Load Capacity

The maximum load that can be applied to the center of the slide table surface and the value that can be driven at maximum speed.

■ Unidirectional Positioning Accuracy

Positioning is performed sequentially at fixed intervals in one direction from the reference point (stroke end). Across the entire stroke, the difference between the actual measured value at each positioning point (from the reference point to the actual moved position) and the theoretical value (the position the command is supposed to move to) is measured and calculated. The maximum difference is defined as the unidirectional positioning accuracy.

■Repeatability

At any given point, perform positioning from the same direction 7 times, measure the deviation of the stop position, and calculate half of the maximum deviation. Repeat this operation at three points: the center and both ends of the stroke. The largest calculated value is defined as the repeatability.

*1 The cables inside the dashed box are 2-meter or 4-meter cables.

■ Maintenance of the Slide Table

There is no unified regular maintenance standard due to differences in grease types and operating environments. Depending on the drive conditions and the type of guide rail, please be sure to check the grease at least once a month.

■ About Wiring

The motor and sensor cables of this product use a cable + connector configuration. If the cable on the slide table side is frequently bent, it may cause the cable tie to break, which can lead to loose motor and sensor terminals, resulting in poor contact or broken wires. It is recommended to secure the connector on the slide table side when routing the cables.

Images are for reference only.

Images are for reference only.| Electronics/Home Appliances | Automotive | Medical | ||

|  |  | ||

| Smartphones | Semiconductors | Lithium batteries | ||

|  |  |

| Stepper driver | High-precision X-axis automatic stage | Medium-precision X-axis automatic stage | ||

|  |  | ||

| Representative model: C-DR42A | Representative model: XMSG413-LA24-C-N | Representative model: XMBS415-L-N |

The compatible driver supports dual pulse and pulse + direction control. For installation dimensions and user manual, please refer to: E-DR42B.

■ Bus Driver

For installation dimensions and user manual of the driver, refer to Leadshine DM3C-EC522

■ Positioning Pin Drawing

| Direction of movement | ||||||

| X axis | Rotary axis | Goniometer | Z axis | Multi-axis combination | ||

| Guide mechanism |  Linear ball | Thin type, repeatability ±1.5µ Standard type, repeatability ±1µ Standard type, repeatability ±1.5µ With recirculator, standard type, repeatability ±1.5µ/±2µ With recirculator, standard type, repeatability ±1µ With recirculator cover, standard type, repeatability ±1µ Repeatability ±5µ | — | — | Lifting type Repeatability ±5µ Repeatability ±5µ | Repeatability ±5µ |

Crossed roller | Repeatability ±1.5µ Repeatability ±1µ | — | Repeatability ±0.006° Repeatability ±0.01° | Repeatability ±1µ | Repeatability ±0.01° | |

| Displacement mechanism |  Ball screw | — | Repeat positioning accuracy ±0.005° Repeat positioning accuracy ±0.01° | — | — | — |

Worm gear and worm | — | Repeatability ±0.05° Repeatability ±0.08° | — | — | — | |