Floating Joints Quick Connection Type With Holder

Caution

- Easy to install, compact design ensuring strength, and saving cost.

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part14 CLICK here

Product Description

・ Product type: Floating Joints Quick Connection Type with Holder, C-FJRHA series.

・ Connecting Thread x pitch: M4 x 0.7, M5 x 0.8, M6 x 1.0, M8 x 1.25, M10 x 1.25

・ Connects Floating Joints to driven workpiece, absorbing lateral misalignment

・ Miniaturized design post-strength testing, reducing installation area by over 30%.

・ Shortened connection length by more than 20%, easing installation accuracy requirements.

・ Hard chrome-plated surface treatment for excellent abrasion resistance, ensuring rust and abrasion resistance.

・ This is an economy item; The price is cheaper than the MISUMI standard product.

Product Overview of Floating Joints

Product Feature of Floating Joints

Feature 2: The connection length of Floating Joints is shortened by more than 20%, and the installation area is reduced by more than 30%.

Feature 3: Floating Joints can reduce the requirements on installation accuracy (coaxiality or concentricity) between the Floating Joints and the driven workpiece.

Feature 4: Hard chrome-plated surface treatment Floating Joints with excellent abrasion resistance, ensuring anti-rust and abrasion-resistant performance.

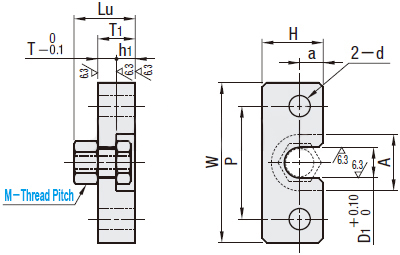

Dimensional Drawing of Floating Joints

Specifications Overview of Floating Joints

| Type of Floating Joints | Floating Joints Type |  Floating Joints Material Floating Joints Material |  Holder Material Holder Material |  Surface Treatment Surface Treatment |  Surface Hardness Surface Hardness |

| C-FJRHA | C-FJR | Equivalent to SUM material | General structural steel | Hard Chrome Plated | 750HV to |

| Part Number | Floating Joints connector | Holder | |||||||||||||||

Type Type |  M-Pitch M-Pitch | T | D | L | h | B | (C) | D1 | A | T1 | h1 | W | H | a | P | d | Lu |

| C-FJRHA | 4-0.7 | 3 | 7 | 5 | 3 | 10 | 11.5 | 8 | 14 | 7 | 4 | 32 | 13 | 5 | 23 | 4.5 | 12 |

| 5-0.8 | 3 | 8 | 6 | 3 | 12 | 13.9 | 9 | 16 | 7 | 4 | 34 | 14 | 5 | 25 | 4.5 | 13 | |

| 6-1.0 | 4 | 10 | 7 | 4 | 14 | 16.2 | 11 | 19 | 9 | 5 | 41 | 16.5 | 6 | 30 | 5.5 | 16 | |

| 8-1.25 | 4 | 13 | 8 | 4 | 17 | 19.6 | 14 | 22 | 9 | 5 | 44 | 20 | 8 | 33 | 5.5 | 17 | |

| 10-1.25 | 5 | 16 | 8 | 4 | 21 | 24.2 | 18 | 27 | 10 | 5 | 51 | 24 | 9 | 39 | 6.6 | 18 | |

Precautions of Floating Joints

This product is only used to absorb the tiny (lateral misalignment) or (angular misalignment) between the Floating Joints and the driven workpiece in linear motion. Never use it for rotating motion connection

② Be sure to use a Floating Joints equipped with a cushioning mechanism

When the driven workpiece is stopped, do not let the Floating Joints be subjected to impact force. Be sure to use a Floating Joints equipped with a cushioning mechanism (rubber or air cushioning).

③ In order to prevent the driven workpiece from losing control, please set up a stop cushioning structure externally.

When the connecting thread is subjected to excessive impact load, it may cause damage to the of Floating Joints, make the driven workpiece lose control, and even fall, thus damaging the equipment or causing harm to human body. Therefore, besure to set up a stop cushioning structure externally.

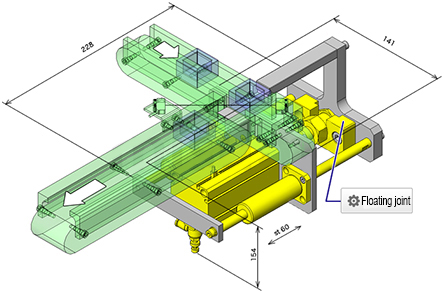

Example Use of Floating Joints

Mechanism function:

During the transportation process, the Floating Joints power can be used to change the moving direction of the workpiece.

Role of Floating Joints:

The Floating Joints push rod and the workpiece ejector rod are connected by a Floating Joints. Because lateral misalignment and angular misalignment are allowed, the installation of the structure becomes convenient and the service life of themechanism is prolonged.

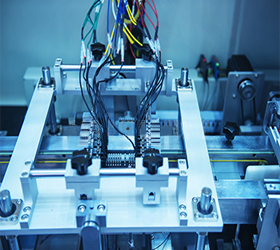

Application Industries of Floating Joints

| Smart phone | Electronic & Electrical Appliances | Lithium battery | ||

|  |  | ||

| Automotive | Robotics | Medical | ||

|  |  |

Related Products of Floating Joints

| Bearing Housing Assembly Single Bearing Type with Retaining Ring | Shaft Supports T Shape Slit | Post Clamp |

|  |  |

| Typical model: BGRAB6000ZZ | Typical model: SHSTM8-25 | Typical model: KDST20 |