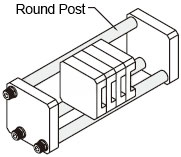

Round Posts One End Threaded, One End Tapped

Caution

- *The surface treatment of this product is electrolytic nickel or electroless nickel plating. Please pay attention

- Download Free! >>Economy Series Catalog ver2023 (TH-EN)_Part13 CLICK here

Product Description

・ Product Type: Round Posts One End Threaded, One End Tapped, C-PETGR series.

・ Round post is essential for connecting, fastening, and supporting across industries like automation, electronics, and more.

・ This is an economy item; The price is cheaper than the MISUMI standard product.

・ Post outer diameter [mm]: 6, 8, 10, 12, 15

・ Overall length [mm]: 20, 30, 40, 50, 60, 80, 100, 120, 150, 200

・ Round post came with flat groove for fastening by wrench.

・ Material: Structural steel or SUM material are generally used

・ Surface treatment: Nickel plating

Economy Round Posts One End Threaded, One End Tapped

- Ideal for diverse applications with one end threaded and one end tapped.

- Durable Construction: Nickel-plated steel ensures long-lasting performance and resistance to rust.

- Available in customizable diameters and lengths to suit your needs.

- High-quality round posts at a lower cost.

- Flat groove design facilitates secure fastening with a wrench in tight spaces.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product Overview of Hexagonal Posts

At the same time, there are a variety of materials to choose from, allowing it to be widely used in automation, electronics and electrical appliances, medical treatment, communication and other fields.

Product Feature of Hexagonal Posts

Feature of Hexagonal Posts 2: a variety of materials to choose from: general structural steel, stainless steel, aluminum, brass, resin, etc.

Feature of Hexagonal Posts 3: a wide range of surface treatments are available to meet the requirements of various industries: ferroferric oxide protective film (blackening treatment), electroless nickel plating, chromate (black), anodize (black, white), etc.

Feature of Hexagonal Posts 4: products with surface treatment (electroless nickel plating) and material (stainless steel SUS304) for good anti-rust performance are widely used in precision equipment and dust-free environment.

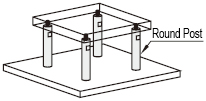

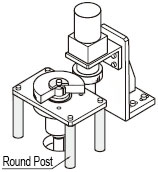

Feature of Hexagonal Posts 5: with the main functions of connection, fastening, support and separation, it is often used in mechanisms with various frames as a connection and support component.

Dimensional Drawing of Hexagonal Posts

Specifications Overview of Hexagonal Posts

| Type of Hexagonal Posts |  Material Material |  Surface Treatment Surface Treatment | D (mm) | L (mm) |

| C-PETGR | Structural steel or SUM material are generally used | Nickel plating | 6~12 | 20~100 |

This product of Hexagonal Posts is not RoHS compliant

This product of Hexagonal Posts is not RoHS compliant Taps may not have been surface treated internally.

Taps may not have been surface treated internally. The surface of the product is barrel plated, so the appearance may have some bumps and bruises.

The surface of the product is barrel plated, so the appearance may have some bumps and bruises. The thread specifications only ensure the actual matching accuracy of screws and nuts.

The thread specifications only ensure the actual matching accuracy of screws and nuts.Usage Method of Hexagonal Posts

| Intended Use of Hexagonal Posts | Support and fixing | Fastening and connection | Separation |

| Usage Method of Hexagonal Posts Diagram |  |  |  |

| Features of Hexagonal Posts | - Hexagonal Posts can bear large load in vertical direction - ±0.05mm can be selected as the minimum tolerance of length specification, which ensures the stability of the mechanism | - Simple and aesthetic connection | - Connected to the baffle to effectively block the mechanism in operation and prevent interference - Hexagonal Posts, Easy to fasten and install in narrow spaces |

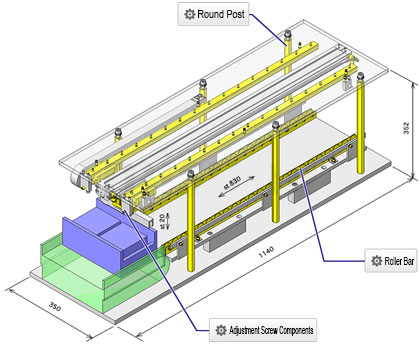

Example Use of Hexagonal Posts

Precautions of Hexagonal Posts

The post is generally fastened by torque method. For bolts, fasten them within the range of fastening torque, otherwise excessive torque will cause thread fracture.

② Anti-rust specification selection and maintenance of Hexagonal Posts.

If there are requirements for anti-corrosion performance, select products with surface treatment of electroless nickel plating or those made of stainless steel (SUS304) when choosing general structural steel products.

General structural steel posts without surface treatment are recommended to be stored in a constant-temperature and dry environment, and regularly applied with anti-rust oil for maintenance.

Application Industries of Hexagonal Posts

| Medical of Hexagonal Posts | Semiconductor of Hexagonal Posts | Electronic & Electrical Appliances of Hexagonal Posts | ||

|  |  | ||

| Smart phone of Hexagonal Posts | Food of Hexagonal Posts | Automotive of Hexagonal Posts | ||

|  |  |

Related Products of Hexagonal Posts

| (Economy series of Hexagonal Posts) Silicon Rubber, Urethane Molded Bearings Flat, with Threaded Shaft | (Economy series of Hexagonal Posts) Strut Clamps Equal Dia., Perpendicular Configuration/Reversed | (Economy series of Hexagonal Posts) Metal Washers Standard Class T Dimension Selection, T Dimension Configurable | ||

|  |  | ||

| Typical model of Hexagonal Posts: UMSWH3-10 | Typical model of Hexagonal Posts: KDST15 | Typical model of Hexagonal Posts: WSSM13-6-5 | ||

| Advantages of Hexagonal Posts: high quality, low price, short delivery time | Advantages of Hexagonal Posts: full range, high precision and high quality | Advantages of Hexagonal Posts: full range of matching shaft products |

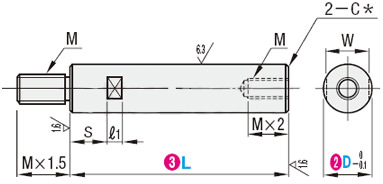

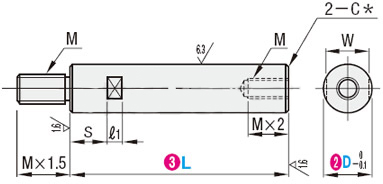

Dimensional Drawing of Hexagonal Posts

Specification Table of Hexagonal Posts

to

to  .

. | Part Number ( Type of Hexagonal Posts· Type of Hexagonal Posts· D) D) | - |  L L | |

| C-PETGR12 | - | 80 |

■Material Specifications of Hexagonal Posts

| Type of Hexagonal Posts |  Material Material |  Surface Treatment Surface Treatment |

| C-PETGR | Structural steel or SUM material are generally used | Nickel plating |

This product of Hexagonal Posts is not RoHS compliant

This product of Hexagonal Posts is not RoHS compliant Taps may not have been surface treated internally.

Taps may not have been surface treated internally. The surface of the product is barrel plated, so the appearance may have some bumps and bruises.

The surface of the product is barrel plated, so the appearance may have some bumps and bruises. The thread specifications only ensure the actual matching accuracy of screws and nuts.

The thread specifications only ensure the actual matching accuracy of screws and nuts.| Part Number of Hexagonal Posts | L (Fixed Size Selection) | M (Coarse Thread) | S | W | ℓ1 | ||||||||

| Type | D | ||||||||||||

| C-PETGR | 6 | 20 | 30 | 40 | 50 | 60 | 3 | 3.5 | 5 | 8 | |||

| 8 | 30 | 40 | 50 | 60 | 80 | 4 | 6 | 7 | 8 | ||||

| 10 | 20 | 30 | 40 | 50 | 60 | 80 | 5 | 6 | 8 | 8 | |||

| 12 | 30 | 40 | 50 | 60 | 80 | 6 | 7.5 | 10 | 10 | ||||

| 15 | 40 | 50 | 60 | 80 | 100 | 8 | 10 | 13 | 10 | ||||

L dimension tolerance is ±0.2

L dimension tolerance is ±0.2