Ball Plungers Stainless Steel, Long Body, SUS Ball/POM Ball

Caution

- Download Free! >> Economy Series Catalog (TH-EN-FY25) CLICK here

Product Description

- Economy series Ball Plungers Stainless Steel, Long Body, SUS Ball/POM Ball

- The series including of C-BSML, C-BSZL, C-NBSML and C-NBSZL

- Main Body Material: Stainless Steel SUS304.

- Ball Material: Stainless Steel SUS304 and POM.

- Spring Material: Stainless Steel SUS304.

- Economy Ball Plunger Mounting Method: Screw (Hex).

- Coarse Thread Size (M): 3, 4, 5, 6 and 8.

- Package Quantity: 10 and 20 PCS (Please check before order)

- Ball Plungers suitable for medical, electronic, and other equipment with high surface requirements.

- For MISUMI Economy series ball plungers without painting and coloring.

Economy Ball Plungers (Stainless Steel, Long Screw, SUS Ball/POM Ball)

- Long Body For Enhanced Stability

- High Load Capacity For Various Applications

- Stainless Steel Construction For Durability

- Suitable For Linear And Rotary Motion Mechanisms

- Easy Installation With Hex Screws

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

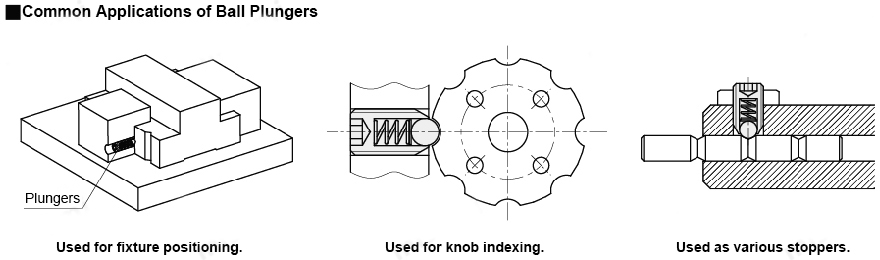

· Ball Plungers, also known as detent screws, ball detent screws, positioning balls, spring-loaded ball plungers, etc., use a spring to push out the front ball through a fixed stroke. They can be used for temporary positioning of workpieces, indexing adjustments, and more.

Product upgrade in progress: the hex socket is being deepened for easier disassembly. Products are shipped randomly. Both pre-upgrade and post-upgrade products are of good quality. Please be aware.

Material Specifications

| Type | Body | Ball | Spring |  Surface Treatment Surface Treatment | |||

Material Material |  Material Material |  Hardness Hardness |  Material Material | ||||

| Stainless Steel Ball Type | Ultra Light Load | E-LBMSL | SUS304 | SUS440C | 55HRC | SUS304 | No |

| Light Load | C-BSML | SUS304 | — | ||||

| Heavy Load | C-BSZL | ||||||

| Ultra Heavy Load | E-LBSXL | SUS440C | 55HRC | ||||

| Resin Ball Type | Ultra Light Load | E-LNMSL | SUS304 | POM | — | SUS304 | |

| Light Load | C-NBSML | ||||||

| Heavy Load | C-NBSZL | ||||||

| Ultra Heavy Load | E-LNSXL | ||||||

| Type |  Package Quantity | d | Stroke S | L | ℓ | B | Light Load | Heavy Load | ||||

Type Type |  Outer Diameter M Outer Diameter M(Coarse Thread) | Stainless Steel Ball | Resin Ball | Load (N) | Load (N) | |||||||

| min. | max. | min. | max. | |||||||||

| C-BSML (Stainless Steel Ball Type · Light Load) C-BSZL (Stainless Steel Ball Type · Heavy Load) C-NBSML (Resin Ball Type · Light Load) C-NBSZL (Resin Ball Type · Heavy Load) | 3 | 20P | 1.5 | 0.5 | 0.5 | 12 | 2 | 1.5 | 1.5 | 3 | 2 | 5 |

| 4 | 2.38 | 0.8 | 0.8 | 16 | 3 | 2 | 2 | 5 | 5 | 20 | ||

| 5 | 3 | 1 | 1 | 4 | 2.5 | 3 | 10 | 5 | ||||

| 6 | 10P | 3.5 | 1.2 | 1.2 | 20 | 5 | 3 | 5 | 15 | 10 | 30 | |

| 8 | 5 | 1.6 | 1.7 | 25 | 6 | 4 | 7 | 20 | 15 | 50 | ||

The minimum load indicates the initial load for reference only, while the maximum load indicates the load when the ball head is pressed in to its maximum limit.

The minimum load indicates the initial load for reference only, while the maximum load indicates the load when the ball head is pressed in to its maximum limit.| Type |  Package Quantity | d | S | L | ℓ | B | Ultra Light Load | Ultra Heavy Load | |||

Type Type |  Outer Diameter M Outer Diameter M(Coarse Thread) | Load (N) | Load (N) | ||||||||

| min. | max. | min. | max. | ||||||||

| E-LBMSL (Stainless Steel Ball Type · Ultra Light Load) E-LBSXL (Stainless Steel Ball Type · Ultra Heavy Load) E-LNMSL (Resin Ball Type · Ultra Light Load) E—LNSXL (Resin Ball Type · Ultra Heavy Load) | *3 | 10P | 1.5 | 0.4 | 13 | 3 | 1.5 | 1 | 2 | 2 | 5 |

| 4 | 2.38 | 0.8 | 15 | 2.5 | 2 | 0.5 | 2 | 4 | 12 | ||

| 5 | 3 | 1.1 | 18 | 3.5 | 2.5 | 1 | 3 | 8 | 25 | ||

| 6 | 3.5 | 1.2 | 20 | 4 | 3 | 2 | 5 | 10 | 40 | ||

| 8 | 5 | 1.7 | 23 | 6 | 4 | 2.5 | 6 | 18 | 50 | ||

| 10 | 6 | 2.2 | 27 | 7 | 5 | 3 | 8 | 22 | 60 | ||

| 12 | 8 | 2.7 | 32 | 9 | 6 | 4 | 10 | 25 | 70 | ||

| 16 | 5P | 10 | 3.7 | 40 | 11 | 8 | 6 | 15 | 40 | 120 | |

The minimum load indicates the initial load for reference only, and the maximum load indicates the load when the ball head is pressed in to its maximum limit.

The minimum load indicates the initial load for reference only, and the maximum load indicates the load when the ball head is pressed in to its maximum limit.· Complete range of specifications to meet various size, length, and load requirements.

· Made entirely of stainless steel, with no painting or coating, making it suitable for equipment with higher surface requirements.

· No wrench slot at the front end; please use with a hex wrench.

· Simple ball plunger structure: the tip ball is pushed out by an internal spring for a fixed stroke, and can be released by overcoming the spring force and pressing in the ball.

· Flexible installation: Suitable for linear and rotary motion mechanisms that require positioning; can be installed with standard threads for easy assembly and disassembly.

· Applicable to various scenarios such as indexing, positioning, and stop limiting of fixtures.

· The stroke can be finely adjusted by changing the screw-in depth.

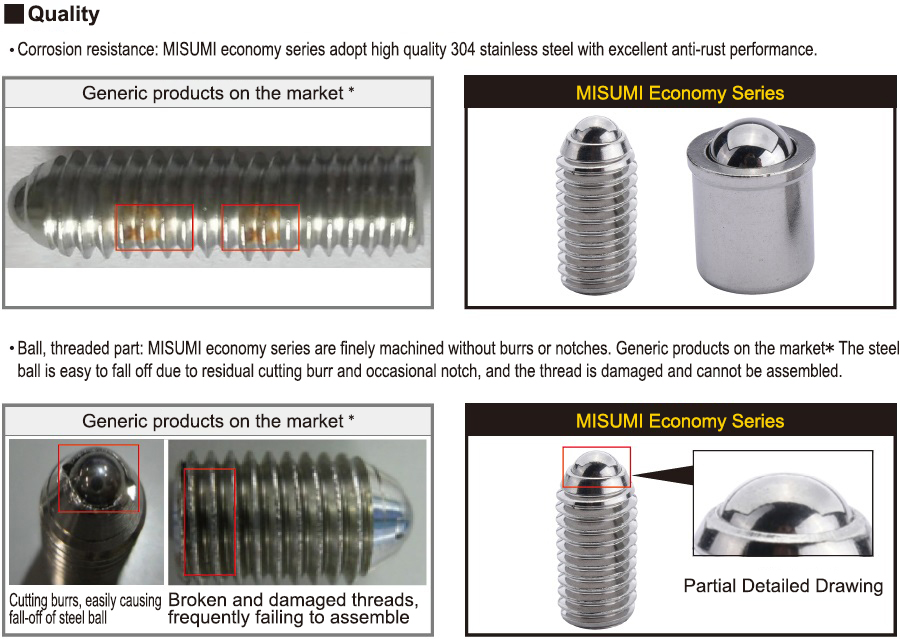

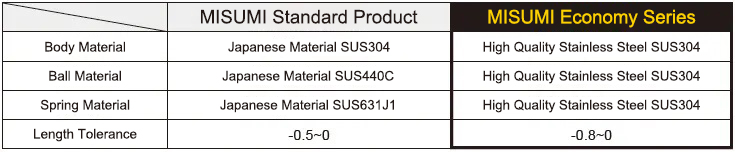

■ Differences between MISUMI Economy Ball Plungers and MISUMI Standard Products

· Except for the zinc-plated type, the body, ball, and spring of the MISUMI economy ball plunger are all made of high-quality stainless steel, with no painting or coloring, making them suitable for equipment with high surface requirements such as medical and electronics.

· Stroke (S), groove size (B), and load are all reference values and not guaranteed values

· No anti-loosening treatment applied