Linear Bushing - Standard, Double[RoHS Compliant]

Caution

- No seal supplied for dr=3 or 4.

- Bushings are applied with anti-rust oil harmless to lubricants. After cleaning (recommended cleaning method: ultrasonic cleaner or white kerosene) and drying the bushings, grease application is recommended before use.

Product Description

Linear Bushing are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Inner Diameter Minimum/Maximum (mm.) : 3 and 50

● Overall Length Minimum/Maximum (mm.) : 23 and 192

● Operating Temperature (℃) :

Standard Type : -20 to 80°C

High Temperature Type : -20 to 120°C

● Material

Housing and Ball - SUJ2 Equivalent

Retainer

Standard Type -Plastic

High Temperature Type - Stainless Steel

[Application]

Linear Bushing are commonly used in various applications in factory automation systems

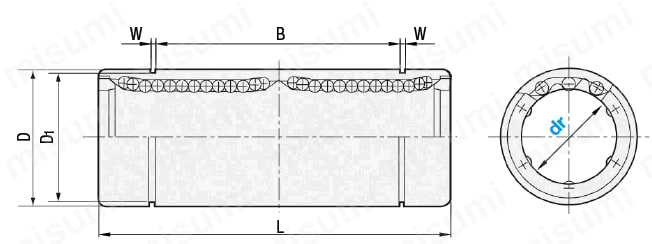

Dimensional Drawing of Linear Bushings

| Type Linear Bushings | Outer Cylinder | Balls | Retainer | Operating Ambient Temperature | [A] Accessory | |||

| [M] Material | [M]Hardness | [S] Surface Treatment | [M] Material | [M] Material | ||||

| Standard Specification | C-LMUW | SUJ2 Equivalent | 58HRC or more | — | SUJ2 Equivalent | Plastic | -20 to 80°C | Seal [M] Material Nitrile Rubber |

| High Temperature Specifications | C-LMUWF−N | Stainless Steel | -20 to 120°C | — | ||||

| C-LMUWMF−N | Electroless Nickel Plating | |||||||

Specification Table of Linear Bushings

| Part Number (Type, dr) |

| C-LMUW10 |

| C-LMUWF−N20 |

| dr | D | L | B | W | D1 | Eccentricity (Max.) | Balls Rows | Basic Load Rating | Allowable Static Moment (N⋅m) | Reference Mass (g) | ||||||

| Surface Treatment | Surface Treatment | C (Dynamic) N | Co (Static) N | |||||||||||||

| Tolerance | Not Provided | Provided | Tolerance | Tolerance | ||||||||||||

| Tolerance | Tolerance | |||||||||||||||

| 3 | +0.003 -0.013 | 7 | +0.006 -0.013 | +0.006 -0.017 | 19 | +0.3 -0.6 | — | — | — | — | 0.02 | 4 | 138 | 210 | 0.51 | 3.2 |

| 4 | 8 | 23 | 176 | 254 | 0.63 | 4.8 | ||||||||||

| 5 | 10 | 28 | 18.2 | 0 -0.4 | 1.1 | 9.6 | 263 | 412 | 1.38 | 11 | ||||||

| 6 | 12 | +0.006 -0.015 | +0.006 -0.020 | 35 | 24.8 | 11.5 | 0.03 | 324 | 529 | 2.18 | 16 | |||||

| 8 | 15 | 45 | 32.8 | 14.3 | 431 | 784 | 4.31 | 31 | ||||||||

| 10 | 19 | +0.006 -0.018 | +0.006 -0.023 | 55 | 41.4 | 1.3 | 18 | 588 | 1100 | 7.24 | 62 | |||||

| 12 | 21 | 57 | 43.4 | 20 | 657 | 1200 | 10.9 | 80 | ||||||||

| 13 | 23 | 61 | 22 | 813 | 1570 | 11.6 | 90 | |||||||||

| 16 | 28 | 70 | 49.8 | 1.6 | 27 | 5 | 1230 | 2350 | 19.7 | 145 | ||||||

| 20 | +0.003 -0.015 | 32 | +0.006 -0.021 | +0.006 -0.027 | 80 | 57.8 | 30.5 | 0.04 | 1400 | 2740 | 26.8 | 180 | ||||

| 25 | 40 | 112 | +0.3 -0.7 | 78.3 | 0 -0.5 | 1.85 | 38 | 6 | 1560 | 3140 | 43.4 | 440 | ||||

| 30 | 45 | 123 | 85.3 | 43 | 2490 | 5490 | 82.8 | 480 | ||||||||

| 35 | +0.003 -0.018 | 52 | +0.006 -0.024 | +0.006 -0.032 | 135 | 94.8 | 2.1 | 49 | 0.05 | 2650 | 6270 | 110 | 795 | |||

| 40 | 60 | 151 | 116.8 | 57 | 3430 | 8040 | 147 | 1170 | ||||||||

| 50 | 80 | 192 | 142.8 | 2.6 | 76.5 | 6080 | 15900 | 397 | 3100 | |||||||

[!] No seal supplied for dr = 3 or 4. No Seal Type has lower sliding resistance (0.4 to 1.2 N) and slides smoothly. Separate dust-proofing measures are necessary to keep the dust entering into sliding parts.

[ ! ] Spacers and Stoppers for Linear Bushings can be selected from here.

[ ! ] For shaft and housing tolerances, see "Recommended Tolerance of Shaft Diameter / Housing Diameter."

| Specifications | Standard | High Temperature | |

| Surface Treatment | Not Provided | Not Provided | Provided |

| dr | C-LMUW | C-LMUWF−N | C-LMUWMF−N |

| * 3 | ● | ||

| * 4 | ● | ||

| 5 | ● | ● | ● |

| 6 | ● | ● | ● |

| 8 | ● | ● | ● |

| 10 | ● | ● | ● |

| 12 | ● | ● | ● |

| 13 | ● | ● | ● |

| 16 | ● | ● | ● |

| 20 | ● | ● | ● |

| 25 | ● | ● | ● |

| 30 | ● | ● | ● |

| * 35 | ● | ||

| * 40 | ● | ||

| * 50 | ● | ||

[ ! ] Only C-LMUW can be selected for dr dimension = 3 or 4.

[ ! ] C-□□□-N cannot be selected for dr* dimension.

| dr | Shaft Dia. | Housing Dia. | |

| g6 Tolerance | Tolerance | ||

| 3 | −0.002 −0.008 | 7 | +0.021 +0.006 |

| 4 | −0.004 −0.012 | 8 | |

| 5 | 10 | ||

| 6 | 12 | +0.024 +0.006 | |

| 8 | −0.005 −0.014 | 15 | |

| 10 | 19 | +0.027 +0.006 | |

| 12 | −0.006 −0.017 | 21 | |

| 13 | 23 | ||

| 16 | 28 | ||

| 20 | −0.007 −0.020 | 32 | +0.031 +0.006 |

| 25 | 40 | ||

| 30 | 45 | ||

| 35 | −0.009 −0.025 | 52 | +0.036 +0.006 |

| 40 | 60 | ||

| 50 | 80 | ||

Cautions/Prohibitions of Linear Bushings

(1) For grease lubrication, apply grease to the ball rows within the linear bushings before use, then periodically apply grease during the use.

The grease has an effect of reducing friction by forming a layer between the balls and shaft rolling surfaces, preventing seizures.

Grease loss and deterioration will cause shorter life of linear guides.

(2) Recommended Grease: Lithium soap based grease

(3) Recommended Lubrication Intervals: Every 6 month

Recommended lubrication is that every 3 months when travel distance is extensive, or every 1000 km when travel distance exceeds 1000 km within the period.

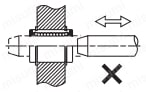

(4) If large moment load (offset load) is to be applied, Short / Single Type Linear Bushings are not suitable.

Use of Double Type or Multiple Linear Bushings is recommended.

■Dust-Proofing Measures of Linear Bushings

Please be aware that if foreign objects or dusts get inside the linear bushing, it will interfere with the circulation of the steel balls and cause failures.

Please attach a dust cover or protection cover for harsh usage environments.

■Use of a hardened shaft with g6 tolerance is recommended for MISUMI Linear Bushings.

How to Use of Linear Bushings

| Illustration | Instructions for Use |

| If large load (offset load) is to be applied, Single Type Linear Bushings are not suitable. Use of Double Type or Multiple Linear Bushings is recommended. |

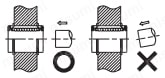

| Linear Bushings are not suitable for rotating motion due to their structure. Forcing to rotate may cause failures. |

| Linear Bushings are not suitable for usage with repetitive insertion and extraction of shafts. |

| When assembling with linear shafts, forcing the shaft into the bushing with angular misalignment may cause the ball retainers to deform and balls to fall out. Be sure to align the centers and insert the shaft gently. |

App. Example of Linear Bushings

▲Example of use in conveyor transfer with air cylinder