(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

Cylinders with Guides(Environment, Applications:Low Friction (Internal Resistance))

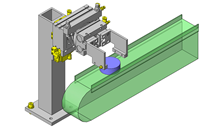

Cylinders with guides are actuators that incorporate the guide and cylinder into a single unit. A guide mechanism needs to be provided since piston rods can bend, rotate or buckle in response to forces such as lateral loads. Using a cylinder with a guide eliminates the need to provide a separate guide mechanism, improving accuracy and rigidity while saving space. The available guide types include linear guides used in combination with the cylinder, and twin rod cylinders that have 2 air-pressure cylinders incorporated into a single unit. When selecting cylinders with guides, the type should be selected to match the objective (positioning, direct diversion, lifting or the like). Other factors to consider when making the selection include the cylinder diameter, stroke and mounting method, as well as the installation location of the mounted equipment (such as a cleanroom or food processing plant).

Configure

Specification/Dimensions

-

Cylinder I.D: D(Ø)

-

Stroke: L(mm)

- 1

- 1,000

- 1,100

- 1,200

- 1,300

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 15+50

- 15+60

- 16

- 17

- 18

- 19

- 20

- 20+18

- 20+25

- 21

- 22

- 23

- 25

- 26

- 27

- 29

- 30

- 30+10

- 30+11

- 30+50

- 31

- 32

- 33

- 35

- 35+35

- 35+75

- 36

- 38

- 40

- 40+40

- 40+85

- 42

- 44

- 45

- 45+45

- 45+55

- 50

- 50+25

- 50+30

- 50+40

- 50+50

- 51

- 53

- 55

- 55+20

- 60

- 60+15

- 60+230

- 63

- 64

- 65

- 68

- 70

- 72

- 74

- 75

- 75A

- 75B

- 75+25

- 75+75

- 76

- 77

- 78

- 80

- 83

- 85

- 90

- 95

- 100

- 100A

- 100B

- 100+0

- 100+5

- 100+20

- 100+75

- 100+125

- 100+200

- 102

- 105

- 105+188

- 110

- 113

- 114

- 115

- 120

- 120+30

- 120+130

- 124

- 125

- 125A

- 125B

- 125+150

- 127

- 128

- 130

- 134

- 135

- 136

- 140

- 144

- 145

- 149

- 150

- 150A

- 150B

- 150+25

- 150+30

- 153

- 154

- 155

- 159

- 160

- 161

- 165

- 170

- 175

- 175+100

- 175+125

- 178

- 180

- 185

- 188

- 190

- 195

- 197

- 198

- 199

- 200

- 200B

- 203

- 205

- 210

- 213

- 215

- 220

- 222

- 225

- 228

- 229

- 230

- 235

- 240

- 245

- 249

- 250

- 250A

- 250B

- 250+50

- 254

- 255

- 260

- 265

- 266

- 267

- 270

- 275

- 276

- 280

- 285

- 288

- 290

- 292

- 300

- 300B

- 305

- 308

- 310

- 315

- 320

- 325

- 330

- 335

- 340

- 345

- 350

- 351

- 355

- 356

- 360

- 365

- 370

- 375

- 380

- 381

- 385

- 390

- 395

- 399

- 400

- 404

- 405

- 406

- 410

- 420

- 425

- 430

- 431

- 432

- 435

- 440

- 445

- 450

- 455

- 456

- 457

- 458

- 460

- 465

- 467

- 470

- 475

- 480

- 485

- 490

- 495

- 500

- 500A

- 505

- 510

- 520

- 525

- 530

- 535

- 540

- 550

- 560

- 570

- 575

- 580

- 585

- 600

- 609

- 610

- 620

- 625

- 630

- 635

- 640

- 650

- 660

- 670

- 675

- 700

- 711

- 720

- 725

- 730

- 750

- 757

- 760

- 762

- 775

- 800

- 850

- 870

- 900

- 920

- 925

- 950

- 966

- 975

- 1000

-

Rod Operation Method

-

Main Body Shape

-

Cylinder Operation Method

-

Additional Function

- Standard

- High Rigidity, High Precision, High-Grade Guide

- With Rod Rotation Stopper

- With Fall Prevention Mechanism

- With Intermediate Stop Function

- With Rod Rotation Stopper Function

- With Speed Adjustment Function

- With Cylinder Thrust Force Doubling Function

- With Stroke Adjustment Function

-

Environment, Applications

- Standard

- Low Friction (Internal Resistance)

- High Speed, High Frequency

- Slow Speed

- Heat Resistant

- No Copper, fluoropolymer Type Material (Partially Plated)

- Clean Room

- Non-use of Copper-zinc Material

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

- 2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

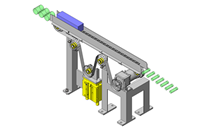

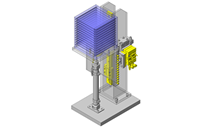

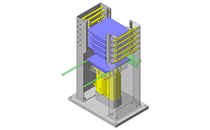

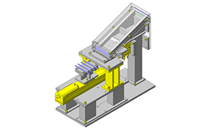

STS Series Cylinder With Multi-Function Guide

CKD

Rectangular, space saving cylinder in which the cylinder switch is integrally housed in the body and overall length of the cylinder is ultimately shortened. The body structure has been optimized for short strokes and long strokes, and guides are provided on both sides to achieve high accuracy, high stiffness, and space saving. There are many variations to suit various applications and environments such as lifters and pushers.

[Features]

·With 2 guide rods that use plain bearings or roller bearings. High non-rotating accuracy and runout accuracy contribute to improving the accuracy of the equipment to be incorporated.

·Cylinder with 2 guide rods, high rigidity and strong lateral load.

·In addition to aluminum (standard), steel (optional) is available as the material for the end plate.

·With the guide rod, it is not necessary to install a separate detent mechanism, which contributes to the compactness of the built-in device.

[Applications]

·Ideal for lifters, pushers, etc.Days to Ship: 12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

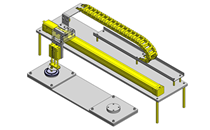

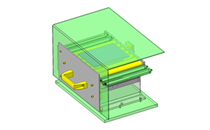

Cylinder With Multifunction Guide, STL Series

CKD

Rectangular, space-saving cylinders in which the cylinder switch is integrally housed in the body. The overall length of the cylinder has been minimized. The body structure has been optimized for short strokes and long strokes. There is a guide on both sides, ensuring high-accuracy, high-rigidity and allowing for use in space-saving applications. Compliant with a broad variety of types for use in different environments and applications, including as a lifter or pusher.

[Features]

· Includes 2-guide rods that use either sliding type or roller type bearings. The high non-rotating accuracy and high runout accuracy helps improve the accuracy of the device to be embedded.

· A cylinder with 2-guide rods, high-rigidity and excellent strength against lateral loads.

· Available with an end plate that is made either of aluminum (standard) or steel (optional).

· The inclusion of the guide rods means there is no need to add a separate anti-rotation mechanism, thus keeping the device to be embedded compact.

[Applications]

· Ideal for lifters, pushers, etc.Days to Ship: 12 Day(s)

12 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Cylinder I.D: D(Ø) |

| Stroke: L(mm) |

| Rod Operation Method |

| Main Body Shape |

| Cylinder Operation Method |

| Additional Function |

| Environment, Applications |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | CKD | CKD |

| Product Series | ||

| CAD |

| |

| From | ||

| Days to Ship | 12 Day(s) | 12 Day(s) |

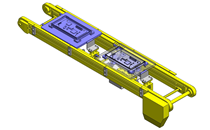

| Cylinder I.D: D(Ø) | 8 ~ 80 | 8 ~ 80 |

| Stroke: L(mm) | 10 ~ 100 | 50 ~ 300 |

| Rod Operation Method | Single-Rod | Single-Rod |

| Main Body Shape | With Guide | With Guide |

| Cylinder Operation Method | Double Acting | Double Acting |

| Additional Function | High Rigidity, High Precision, High-Grade Guide / With Rod Rotation Stopper Function | High Rigidity, High Precision, High-Grade Guide / With Rod Rotation Stopper Function |

| Environment, Applications | Low Friction (Internal Resistance) | Low Friction (Internal Resistance) |

Loading...

Related Categories to Cylinders with Guides

FAQ Cylinders with Guides

- Question: What are Cylinders with Guides?

- Answer: Cylinders with guides are pneumatic or hydraulic actuators that integrate a guide mechanism directly with the cylinder. This design prevents piston rods from bending, rotating, or buckling when subjected to lateral loads, thereby improving the overall accuracy and rigidity of the system. They are commonly used in applications requiring precise linear motion control.

- Question: What are the main types of Cylinders with Guides?

- Answer: There are several types of cylinders with guides, each suitable for different applications:

- Compact Guide Cylinders: These are space-saving and ideal for applications where installation space is limited. They feature a short guide rod to minimize space requirements.

- Dual-Rod Cylinders: These cylinders have two rods for enhanced stability and non-rotational accuracy, making them suitable for applications like pick-and-place operations.

- Guide Rod Cylinders: These include integrated guide rods for higher precision and are often used in conveyor systems and automated machinery.

- Linear Guide Cylinders: These are equipped with linear bearings or bushings for smooth and precise linear motion.

- High-Precision Cylinders: These are designed for applications requiring high rigidity and precision, often featuring advanced guide mechanisms. - Question: How do I choose the right Cylinder with Guide for my application?

- Answer: When selecting a cylinder with a guide, consider the following factors:

- Load Requirements: Determine the maximum load the cylinder will need to support. Choose a cylinder with a suitable guide type that can handle the load without deformation.

- Stroke Length: Select a stroke length that matches your application's requirements. Cylinders come in various stroke lengths, so ensure you choose one that provides the necessary travel distance.

- Precision Needs: For applications requiring high precision, opt for cylinders with linear guides or high-rigidity guides.

- Environmental Conditions: Consider the operating environment. For example, if the cylinder will be used in a high-temperature or clean room setting, select a model designed to withstand those conditions.

- Mounting Options: Ensure the cylinder offers suitable mounting options for your setup. Some cylinders allow mounting from multiple directions to accommodate different installation needs. - Question: What are the benefits of using Cylinders with Guides?

- Answer: - Increased Accuracy: Integrated guides enhance the precision of linear movements, which is crucial for applications requiring exact positioning.

- Space Efficiency: By combining the guide and cylinder into a single unit, these cylinders save space and reduce the complexity of the system design.

- Improved Load Handling: They offer superior load support and resistance to lateral forces compared to standard cylinders, preventing issues like bending or rotation.

- Reduced Maintenance: With integrated guides, there are fewer components that require maintenance, leading to reduced downtime and maintenance costs.

- Versatility: Cylinders with guides are available in various configurations, making them suitable for a wide range of applications, from simple automation tasks to complex industrial processes. - Question: How do I maintain Cylinders with Guides?

- Answer: Proper maintenance of cylinders with guides includes:

- Regular Inspection: Periodically check for wear and tear on the guide rods and seals. Replace any worn components to maintain optimal performance.

- Lubrication: Ensure that the guide rods and bearings are adequately lubricated to minimize friction and wear.

- Cleaning: Keep the cylinder and guide mechanism free from dust and debris to prevent contamination that can lead to malfunction.

- Alignment Check: Regularly verify the alignment of the cylinder and guide to ensure smooth operation and prevent undue stress on the components. - Question: What are common applications of Cylinders with Guides?

- Answer: Cylinders with guides are used in various industrial applications, including:

- Automated Assembly Lines: For precise positioning and movement of components during assembly.

- Conveyor Systems: To control the movement of materials along conveyor belts.

- Packaging Machinery: For accurate and consistent packaging of products.

- Pick-and-Place Systems: In robotics and automation for handling and placing components with precision.

- Testing Equipment: For controlling test fixtures and tools in quality control processes. - Question: How do I troubleshoot common issues with Cylinders with Guides?

- Answer: - Misalignment: If the cylinder is not operating smoothly, check the alignment of the guide and cylinder. Realign as necessary to ensure proper function.

- Leakage: Inspect seals and connections for leaks. Replace any damaged seals or tighten connections to stop the leak.

- Unusual Noise: Excessive noise may indicate wear on the guide or bearings. Lubricate and inspect the components for damage, replacing them if needed.

- Inconsistent Movement: Check for obstructions or contamination in the guide mechanism. Clean and lubricate the cylinder to restore smooth movement. - Question: What is the difference between single-rod and dual-rod cylinders?

- Answer: Single-rod cylinders have one piston rod and are typically used for applications where the load and movement are straightforward. Dual-rod cylinders have two piston rods, providing greater stability and non-rotational accuracy, making them ideal for applications involving higher loads or where precise positioning is required.

- Question: Can Cylinders with Guides be used in cleanroom environments?

- Answer: Yes, some cylinders with guides are designed for cleanroom environments. These models are constructed with materials and finishes that prevent particle generation and contamination. They are suitable for use in sensitive applications such as semiconductor manufacturing and pharmaceutical production.

How can we improve?

How can we improve?