(!) Since support from Microsoft will end on January 14 2020, Windows 7 user might not be able to use MISUMI website effectively. Please consider to update your system as ‘MISUMI Website system requirement’.

- แจ้งวันหยุดทำการในเดือน กรกฎาคมและสิงหาคม 2567 | Notice holiday in July and August 2024 > คลิก

Flat Belt(Surface Cover Shape:Waffle)

Configure

Specification/Dimensions

-

Belt Width(mm)

- 5

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 160

- 170

- 180

- 190

- 200

- 210

- 220

- 230

- 240

- 250

- 260

- 270

- 280

- 290

- 300

- 310

- 320

- 330

- 340

- 350

- 360

- 370

- 380

- 390

- 400

- 410

- 420

- 430

- 440

- 450

- 460

- 470

- 480

- 490

- 500

[10-1200/5mm Unit(s)]

-

Belt Specifications

- General Purpose

- Compliant with Food Sanitation Law.

- For Mini Belt Conveyor

- Antibacterial/Antifungal

- Knife Edge

- Inclined Transfer

- Excellent in Sliding Property

- Conductive

- Heat Resistant

- Oil Resistant

- Non-adhesive Characteristics

- Electronic Parts Transfer

-

Surface Cover Material

- Polyurethane

- Polyester Impregnated Woven Cloth

- Rubber (NBR Nitrile Rubber )

- Rubber (EPDM)

- Polyamide

- SUS304H

- Silicon Rubber

- Vinyl Chloride

- Special Rubber

- Fluororesin

- Cotton

- Thermoplastic Elastomer

- Suede like Non-woven Fabrics

-

Surface Cover Color

- White

- Green

- Navy

- Black

- Silver

- Blue

- Ivory

- Brown

- Gray

- Colorless

-

Surface Cover Shape

-

Tension Member Material

-

Meandering Prevention Crosspiece

-

Endless Type

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

- 3 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

MISUMI

Flat Belts-Food Transfer

This conveyor belt is not only ideal for use in mini belt conveyor systems but also boasts food industry. It is available in a wide range of sizes to suit your needs.

[Feature]

● Belt Width Minimum / Maximum (mm.) : 10 mm. and 500 mm.

● Thickness (mm.): 0.8, 1.3, 1.4 and 1.7

● Belt Length (m.) : The size is configurable between 0.5 to 20 m, and the minimum length can be increased by increments 0.01 m.

● Suitable for Minimum Pulley Belt Diameter Size (mm.) : 15, 20, 30, 50 and 100

● Surface Cover Material: Thermoplastic Polyurethane

● Color: White and Sky Blue

[Application]

It is used in conjunction with pulleys to transfer materials in a conveyor system.Days to Ship: 9 Day(s)

9 Day(s)

-

You can add up to 6 items per a category to the compare list.

Mamaline Tailorbelt-U Non Sticky, Polyurethane

MITSUBOSHI BELTING

It is clean, brightly colored and supports food and logistics applications

Adopts special polyurethane with incredible water and mildew resistance.

Complies with the Food Sanitation Act of Japan (Japanese Ministry of Health, Labour and Welfare Notice No. 370) and can be used widely for transporting unpackaged food, cardboard boxes, or plastic.Days to Ship: 10 Day(s)

10 Day(s)

-

You can add up to 6 items per a category to the compare list.

LOGISTAR Tailorbelt-V For Inclined Conveyance (Inclination Angle Standard 10°or Less)

MITSUBOSHI BELTING

Suitable for a wide range of applications from transporting cardboard boxes to agricultural products

Adopts high-quality PVC with outstanding oil, chemical, ozone and abrasion resistance.

Can also support transportation of logistics applications to machine parts, steel plates, building boards, etc.Days to Ship: 10 Day(s)

10 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Belt Width(mm) |

| Belt Specifications |

| Surface Cover Material |

| Surface Cover Color |

| Surface Cover Shape |

| Tension Member Material |

| Meandering Prevention Crosspiece |

| Endless Type |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MITSUBOSHI BELTING | MITSUBOSHI BELTING |

| Product Series | LOGISTAR Tailorbelt-V For Inclined Conveyance (Inclination Angle Standard 10°or Less) | ||

| CAD |

| ||

| From | |||

| Days to Ship | 9 Day(s) | 10 Day(s) | 10 Day(s) |

| Belt Width(mm) | 10 ~ 500 | 10 ~ 1200 | 10 ~ 1200 |

| Belt Specifications | Compliant with Food Sanitation Law. / For Mini Belt Conveyor | Compliant with Food Sanitation Law. / Antibacterial/Antifungal / Conductive / Non-adhesive Characteristics | Inclined Transfer / Conductive |

| Surface Cover Material | - | Polyurethane | Vinyl Chloride |

| Surface Cover Color | White / Blue | White / Blue | Black |

| Surface Cover Shape | Waffle | Waffle | Waffle |

| Tension Member Material | Polyester | Polyester | Polyester |

| Meandering Prevention Crosspiece | - | - | - |

| Endless Type | - | Finger | Step Type Butt Welding |

Loading...

Related Categories to Flat Belt

FAQ Flat belt

- Question: What types of materials are used for flat belt surface covers?

- Answer: The belt surface’s material can be divided into 2 groups.

1. PVC, PU: mostly used in medical and food industries because they're resistant to chemicals and contamination. And it doesn’t become powder after being damaged.

2. Rubber: it can be divided by type of work.

2.1 Oil Resistant materials, such as SBR and NBR, are used to transport materials containing oil.Because it has low oil absorbency.

2.2 Wear resistant materials such as BR and NR are used in heavy industry because they absorb friction and compressed force well.

2.3 Heat resistant materials such as CR, EPDM, and SI can be used in high temperatures and are chemically resistant. - Question: What are some common problems that can occur with flat belts, and how can they be prevented?

- Answer: 1. Belt edge damage: the cause is a misalignment of the pulley that made the belt scrape the edge of the conveyor until it was damaged. It can be prevented by tightening the bolt and nut of the bearing housing.

2. Belt slack: it can be fixed by adjusting the tension of the conveyor.

3. Belt surface damaged: the cause is that the size of the belt and pulley is inappropriate.

4. Belt Rip: in many cases, this could happen from sharpening materials such as conveyor structures or broken rollers. It can be prevented by doing preventive maintenance on time. - Question: What factors should be considered when selecting a flat belt for a particular application?

- Answer: 1. Choose the conveyor’s material that matches the product being conveyed. Example: use PU conveyors for the medication and food industries.

2. The width of the belt has to match the product being conveyed. meaning the product has to not be too close to the belt’s edge.

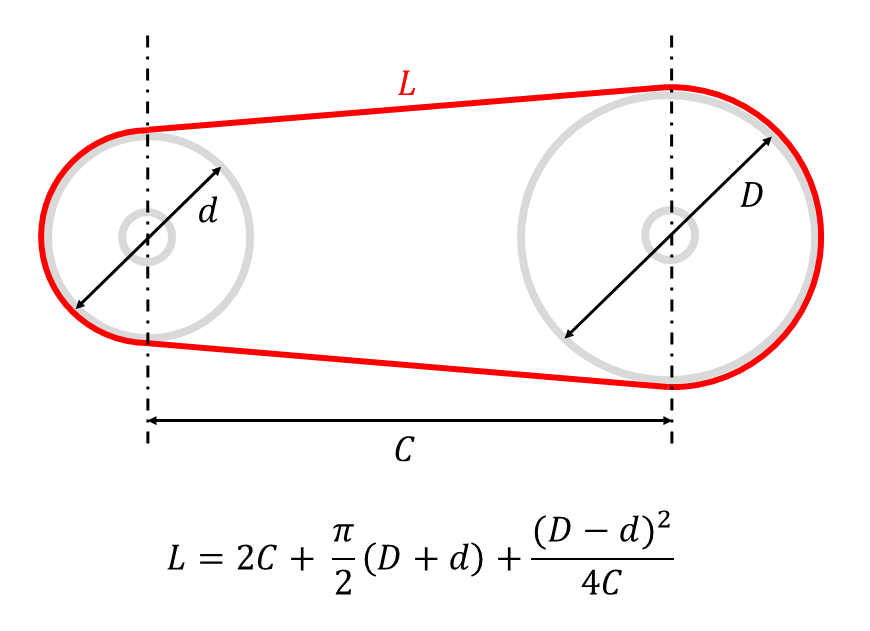

3. Choose the conveyer’s belt that matches the belt speed. if the working’s speed isn’t appropriate to the type of conveyor. It’s going to cause damage and other problems to the conveyor, like belt slack. - Question: How do you calculate the length of a flat belt? Please use the picture "Belt Length Formula1"

- Answer: the formula to calculate length conveyor’s flat belt for 2 pulley system:

if L = Overall length of belt

D = Diameter of large pulley

d = Diameter of small pulley

C = The distance between diameter of large and small pulley

How can we improve?

How can we improve?